Preparation method of PbSe quantum dot near-infrared light-emitting diode

A light-emitting diode and near-infrared technology, applied in the field of optoelectronics, can solve the problems of difficulty in adjusting the emission wavelength of near-infrared light, unable to meet the requirements of near-infrared light applications, affecting the performance of gas detection systems, etc., and achieve the effect of high quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of a PbSe quantum dot near-infrared light-emitting diode, comprising the following steps:

[0028] Step 1: Add 5ml of OA, 12ml of ODE and 0.892g of PbO powder into the three-necked flask, then inject nitrogen into the three-necked flask to completely remove the air inside the three-necked flask;

[0029] Step 2: heating the three-necked flask to 176°C until the PbO powder completely disappears, and the mixed solution in the three-necked flask becomes colorless;

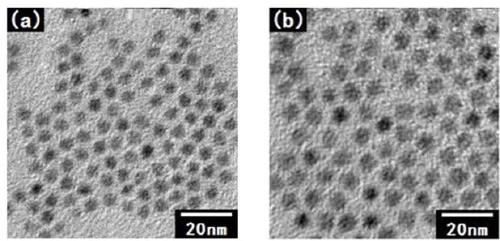

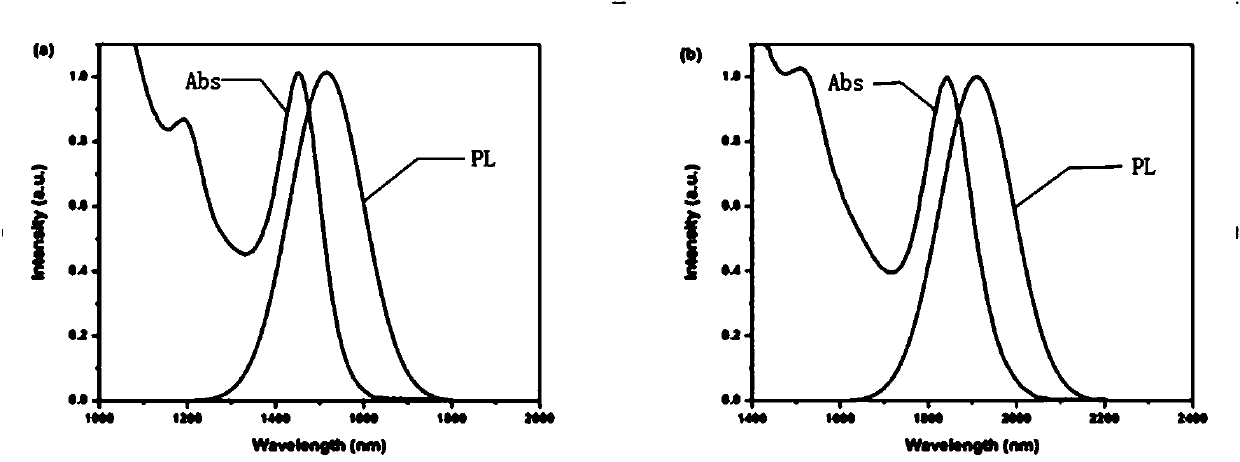

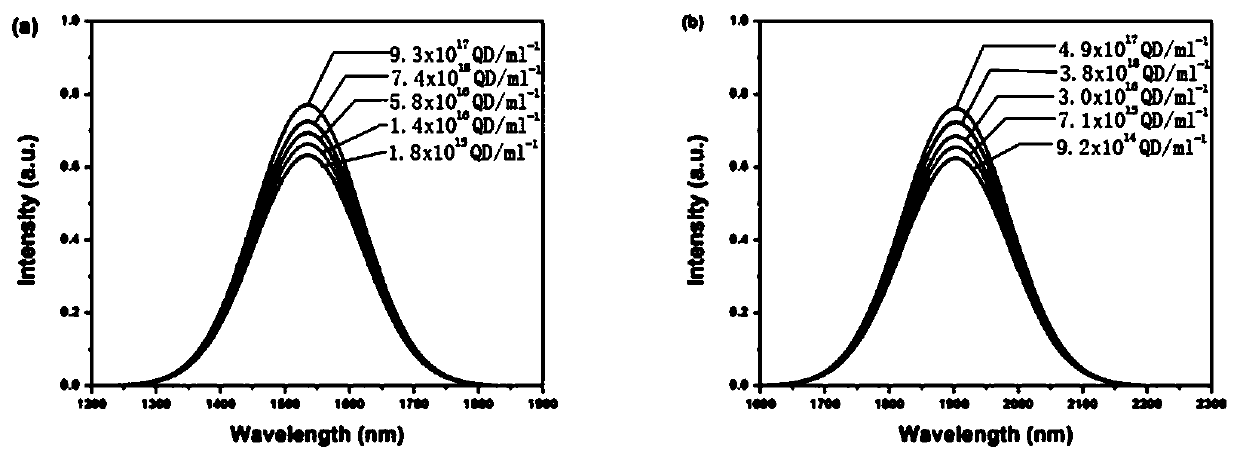

[0030] Step 3: Add 6.9ml of Se-TOP solution into the three-necked flask. The Se-TOP solution contains 0.64g of Se powder. Heat the three-necked flask at 143°C for 2 minutes to obtain a diameter of 4.64 nm PbSe QDs samples;

[0031] Step 4: Add 30ml of toluene into the three-necked flask, and then immerse the three-necked flask in a water bath at room temperature to completely quench the reaction;

[0032] Step 5: The PbSe QDs sample is precipitated and redispersed with methanol and ethane...

Embodiment 2

[0035] A preparation method of a PbSe quantum dot near-infrared light-emitting diode, comprising the following steps:

[0036] Step 1: Add 5ml of OA, 12ml of ODE and 0.892g of PbO powder into the three-necked flask, then inject nitrogen into the three-necked flask to completely remove the air inside the three-necked flask;

[0037] Step 2: heating the three-necked flask to 176°C until the PbO powder completely disappears, and the mixed solution in the three-necked flask becomes colorless;

[0038] Step 3: Add 6.9ml of Se-TOP solution into the three-necked flask. The Se-TOP solution contains 0.64g of Se powder. Heat the three-necked flask at 130°C for 7 minutes to obtain a diameter of 6.03 nm PbSe QDs samples;

[0039] Step 4: Add 30ml of toluene into the three-necked flask, and then immerse the three-necked flask in a water bath at room temperature to completely quench the reaction;

[0040] Step 5: The PbSe QDs sample is precipitated and redispersed with methanol and ethane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com