Long-wave broadband ultraviolet excited multi-functional fluorescent glass and preparation method thereof

A luminescent glass and multi-functional technology, which is applied in the field of multifunctional luminescent glass excited by long-wave broadband ultraviolet light and its preparation, can solve the problems of narrow absorption spectrum, application limitations, and low brightness, and achieve high transparency, high luminous efficiency, and high chemical efficiency. and the effect of optical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

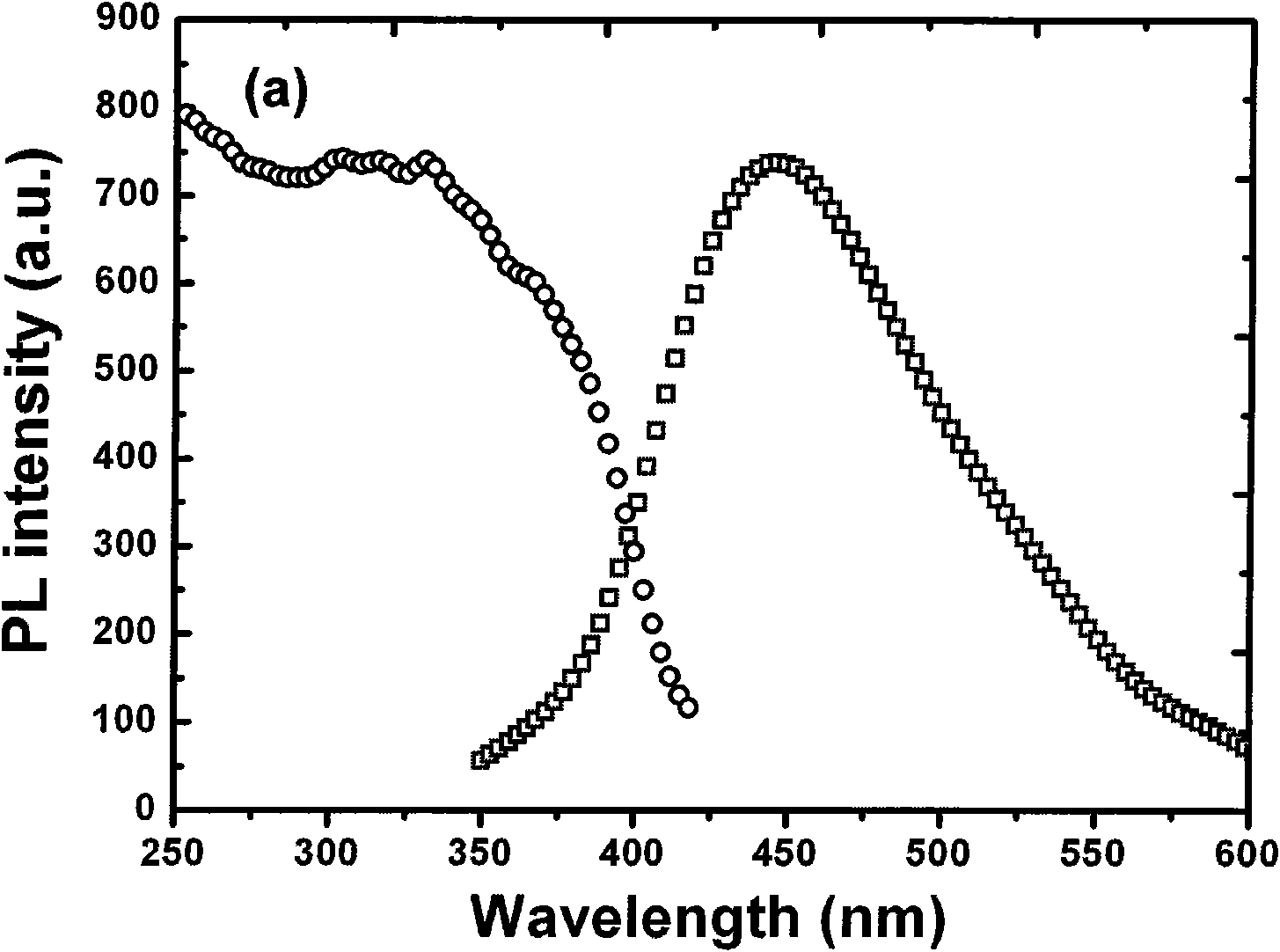

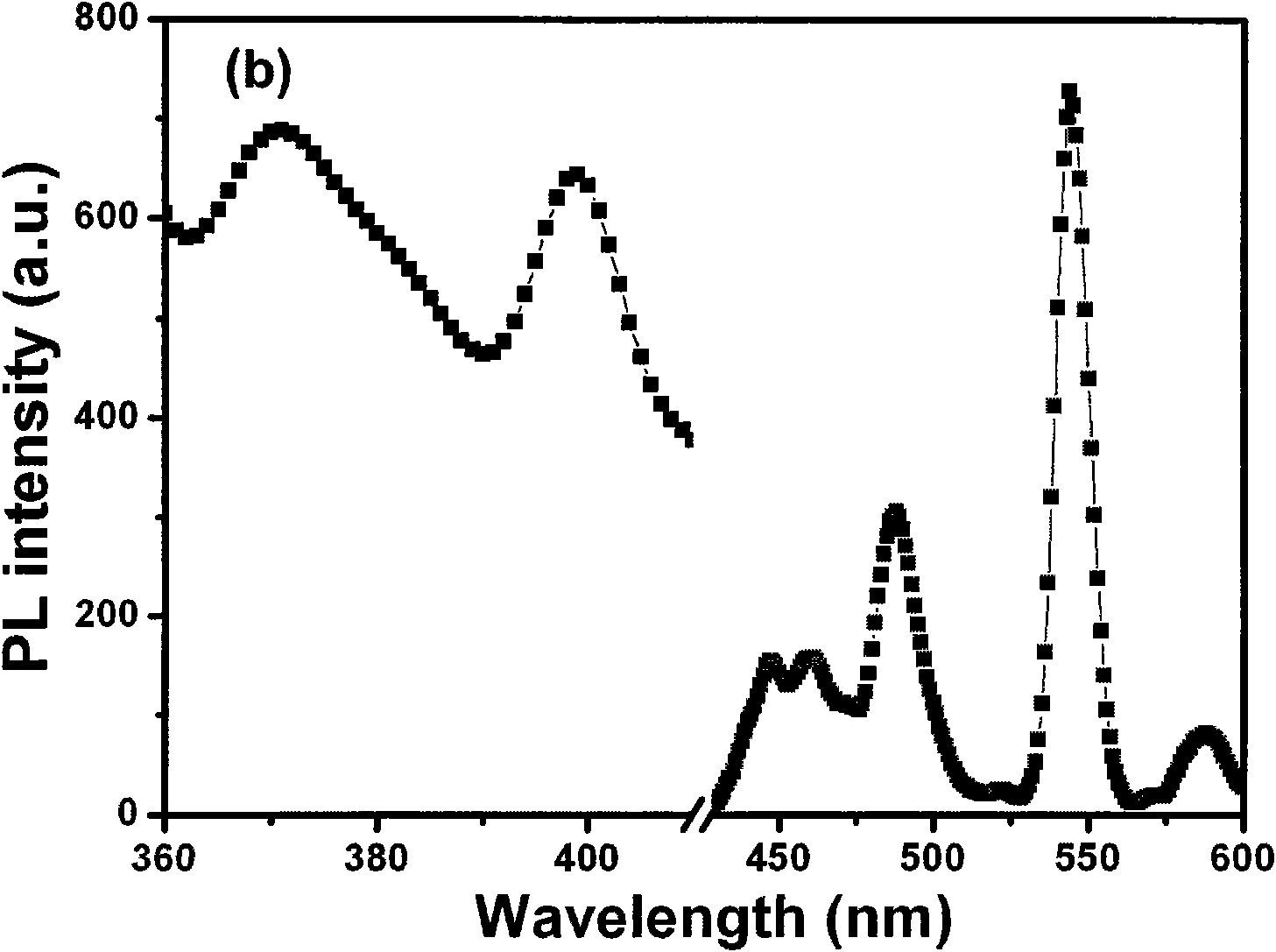

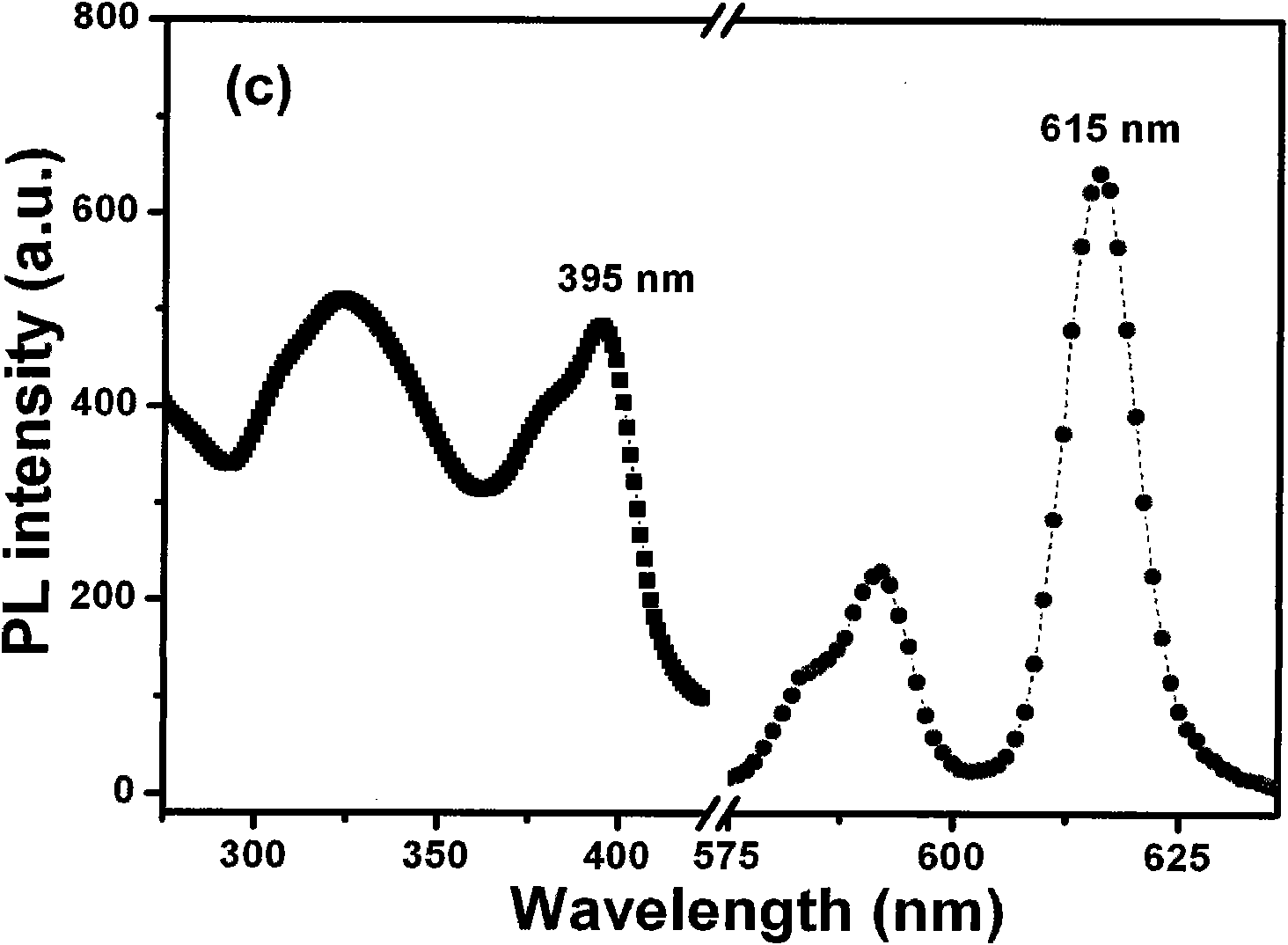

[0026] Take 0.0035mol 13X type zeolite (Na 2 O·Al 2 o 3 2.8SiO2 2 ·6H 2 O) drop into 30ml of 0.1mol / L EuCl 3 solution, stirred for 1 hour, placed in a water bath at 80°C for 24 hours, centrifuged to remove the supernatant, and dried in an oven at 100°C. The resulting precursor was mixed with 0.4211gSiO 2 After fully mixing, put it into a 30mL crucible, place it in a high-temperature furnace and sinter at 1500°C for 8 hours to obtain the target product. Its composition is determined by elemental analysis (ICP): SiO 2 0.21Al 2 o 3 0.08Eu 2 o 3 , has high transparency, and emits red light under 380nm ultraviolet light.

Embodiment 2

[0028] Take 0.0035mol 13X type zeolite Na 2 O·Al 2 o 3 2.8SiO2 2 ·6H 2 O into 30ml of 0.5mol / L EuCl 3 solution, stirred for 1 hour, placed in a water bath at 80°C for 20 hours, centrifuged to remove the supernatant, and dried in an oven at 100°C. The resulting precursor was mixed with 0.4211g SiO 2 After fully mixing, put it into a 30mL crucible, place it in a high-temperature furnace and sinter at 1450°C for 10 hours to obtain the target product. Its composition was determined by elemental analysis (ICP), and its composition was SiO 2 0.21Al 2 o 3 0.12Eu 2 o 3 , Under the irradiation of 380nm ultraviolet light, it emits red light.

Embodiment 3

[0030] Take 0.004mol 4A type zeolite Na 2 O·Al 2 o 3 2SiO2 2 4.5H 2 O into 30ml of 0.1mol / L EuCl 3 solution, stirred for 1 hour, placed in a water bath at 80°C for 24 hours, centrifuged to remove the supernatant, and dried in an oven at 100°C. The resulting precursor was mixed with 0.004mol SiO 2 After fully mixing, put it into a 30mL crucible, place it in a high-temperature furnace and sinter at 1450°C for 10 hours to obtain the target product. Its composition was determined to be SiO by elemental analysis (ICP) 2 0.33Al 2 o 3 0.11Eu 2 o 3 , Under the irradiation of 380nm ultraviolet light, it emits red light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com