Electrochemical machine tool for removing internal-crossing array small-hole burrs

An electrochemical machining and cross-array technology, which is applied in the field of the structure and control system of electrochemical deburring machine tools, can solve the problems of difficulty in workpiece positioning and distribution of electrolyte, and no machine tool for removing burrs from small holes in a circular array, etc. Simple, high similarity of rounded corners, good positioning and clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

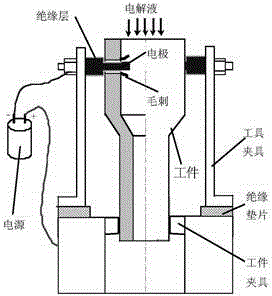

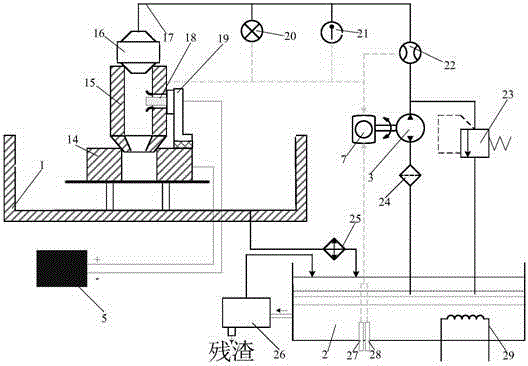

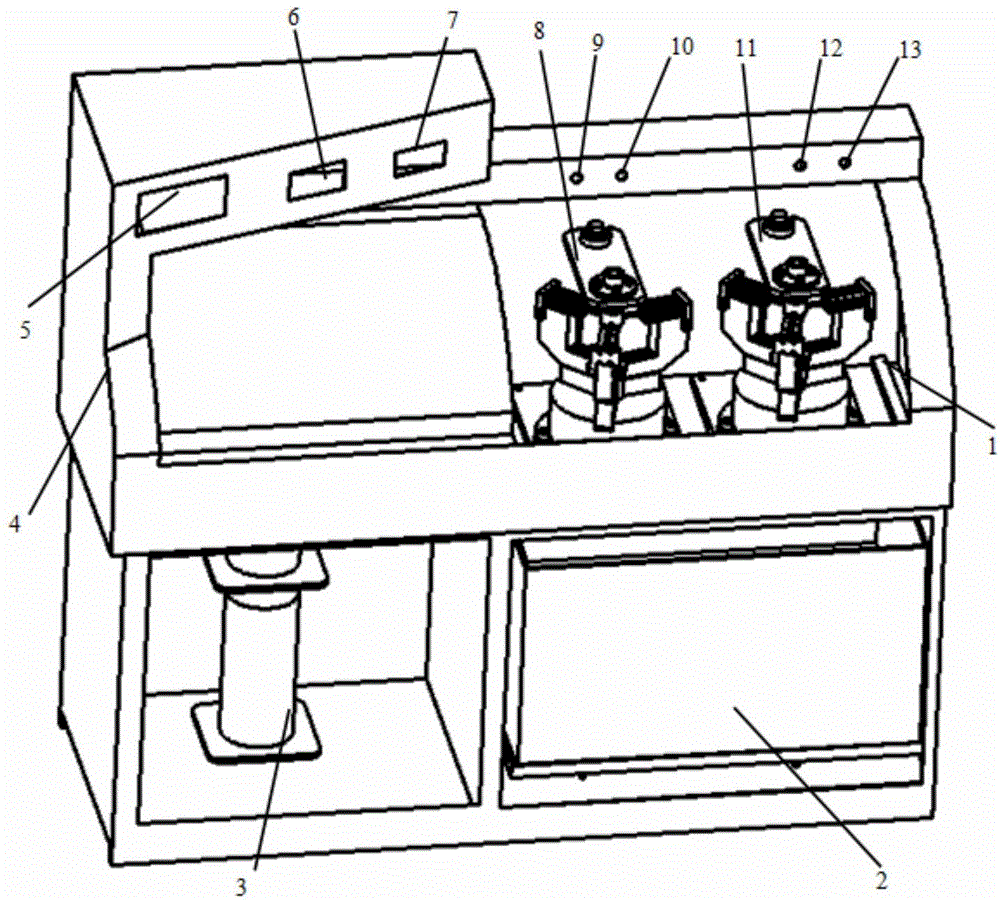

[0019] Such as Figure 1 ~ Figure 4 As shown, the present invention mainly includes machine tool body 4, power supply 5, electrolyzer 2, pipeline 17, filter 24, stainless steel water pump 3, overflow valve 23, flow meter 22, thermometer 21, pressure gauge 20, working box 1, Cooler 25, precipitation centrifugal separator 26, pH value detection sensor 27, conductivity sensor 28, heater 29, control system 7, electrode 18, two sets of fixtures 8, 11 and corresponding fixture action controllers 9, 10, 12, 13. The tooling fixture is made up of workpiece fixture 14, electrode fixture 19 and nozzle device 16, and described flow meter 22, thermometer 21, pressure gauge 20, pH value detection sensor 27 and conductivity sensor 28 can be integrated together and form detection system 6, Placed on the upper left side of the machine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com