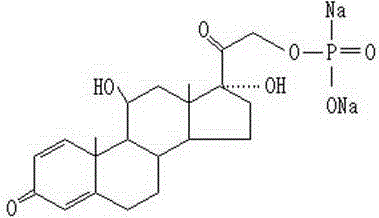

A kind of production technology of prednisolone sodium phosphate

A technology for prednisolone sodium phosphate and prednisolone phosphate is applied in the field of chemical pharmacy and achieves the effects of simple process route, low cost and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Weigh 100g of prednisolone phosphate, dissolve it in 500ml of methanol, add 550ml of purified water after dissolving, add dropwise sodium hydroxide aqueous solution to adjust the pH value to 9.5, control the temperature at 15-20°C, filter the feed liquid, and pour the feed liquid into Add 2200ml of ethanol to the dilution tank, stir to obtain a large amount of crystallization, then let it stand, overnight, filter, and dry after obtaining the material. The product quality meets the standards of EP6.0 and USP31.

Embodiment 2

[0015] Weigh 100g of prednisolone phosphate, dissolve in 450ml of methanol, and add 600ml of purified water after dissolving. Add sodium hydroxide aqueous solution dropwise to adjust the pH value to 9.4, control the temperature at 15-20°C, and filter the feed liquid. The feed solution is poured into a dilution tank with 2000ml of ethanol, stirred to obtain a large amount of crystallization, left standing, overnight, filtered, and dried after obtaining the feed. The product quality meets the standards of EP6.0 and USP31.

Embodiment 3

[0017] Weigh 100g of prednisolone phosphate, dissolve it in 450ml of methanol, add 550ml of purified water after dissolving, add dropwise sodium hydroxide aqueous solution to adjust the pH value to 9.6, control the temperature at 20-25°C, filter the feed liquid, and pour the feed liquid into Add 1800ml of ethanol to the dilution tank, stir to obtain a large amount of crystallization, then stand still, filter overnight, and dry after obtaining the material. The product quality meets the standards of EP6.0 and USP31.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com