Synthesis method for anti-staphylococcus aureus double-activity gallic acid-sulfated bagasse xylan

A technology based on gallic acid and staphylococcus, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, and microorganism measurement/inspection. It can solve the problems of insufficient anti-biological activity and achieve broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

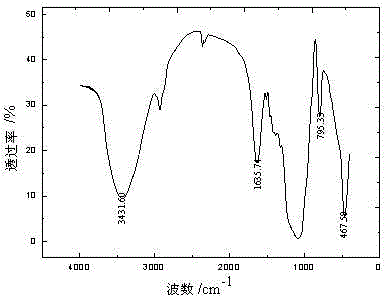

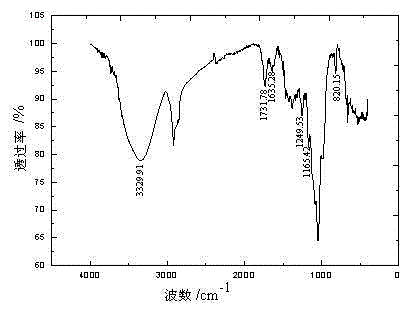

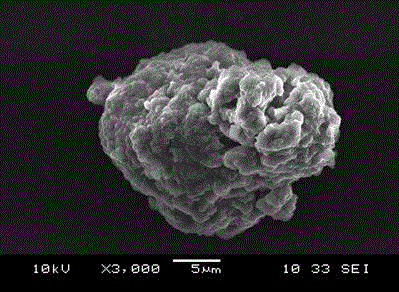

Image

Examples

Embodiment 1

[0049] (1) Weigh 3.0 g of bagasse xylan and dry it in a vacuum oven at 60° C. to constant weight to obtain dry basis bagasse xylan.

[0050] (2) Add 30 mL of ethanol solution with a mass fraction of 60% into a 250 mL four-neck flask, and install a stirrer and a reflux condenser.

[0051] (3) Add 0.5 g of ammonium sulfate to the resultant of step (2), and dissolve it under stirring to obtain an ethanol solution of ammonium sulfate.

[0052] (4) Add 2.5 g of bagasse xylan obtained in step (1) to the ammonium sulfate ethanol solution obtained in step (3), and stir evenly at a temperature of 25° C.

[0053] (5) Control the reaction temperature to be 10°C, add 3mL of concentrated sulfuric acid with a mass fraction of 98% dropwise to the mixed solution obtained in step (4) under stirring, control the dropwise addition within 30 minutes, and continue to React for 3 hours.

[0054] (6) Pour the mixture in step (5) into a beaker, add 10 mL of absolute ethanol to it, and precipitate o...

Embodiment 2

[0072] (1) Weigh 5.0 g of bagasse xylan and dry it in a vacuum oven at 60° C. to constant weight to obtain dry basis bagasse xylan.

[0073] (2) Add 50mL of absolute ethanol solution into a 250mL four-neck flask, and install a stirrer and a reflux condenser.

[0074] (3) Add 2.0 g of ammonium sulfate to the resultant of step (2), and dissolve it under stirring to obtain an ethanol solution of ammonium sulfate.

[0075] (4) Add 4.0 g of bagasse xylan obtained in step (1) to the ammonium sulfate ethanol solution obtained in step (3), and stir evenly under the condition that the temperature is 10-50° C.

[0076] (5) Control the reaction temperature to be 0°C, add 10mL of concentrated sulfuric acid with a mass fraction of 98% dropwise to the mixed solution obtained in step (4) under stirring, control the dropwise addition within 50 minutes, and continue after the dropwise addition React for 6 hours.

[0077] (6) Pour the mixture in step (5) into a beaker, add 20 mL of absolute e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com