Mixed fatty acid modified smell eliminating matt alkyd resin and preparation method thereof

A technology of mixing fatty acids and alkyd resins, which is applied in the field of coatings, can solve the problems of solvent gradient volatility, fullness, leveling performance, hardness, scratch resistance, transparency and matting performance, etc., to achieve excellent cleanness. Odor and solvent gradient volatility, good matting effect, high fullness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

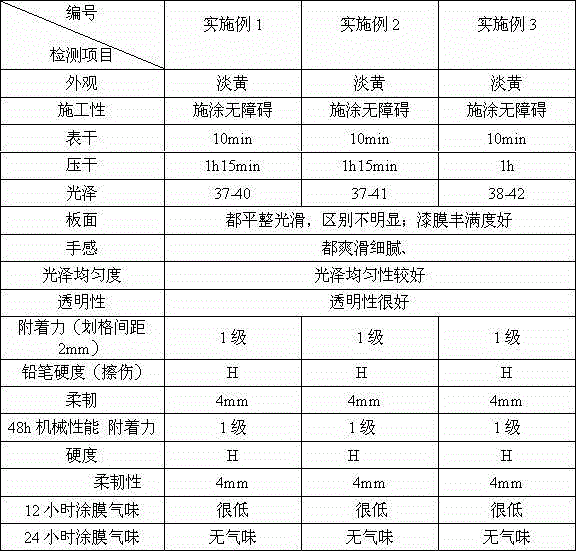

Examples

Embodiment 1

[0023] Add 200 g of oleic acid, 30 g of isooctanoic acid, 30 g of isononanoic acid, 40 g of isophthalic acid, 180 g of pentaerythritol, and 60 g of glycerol in a 2000 mL four-neck flask equipped with a stirring device, a thermometer, and nitrogen protection. , 50 neopentyl glycol, 220 g phthalic anhydride, 30 g xylene, 1 g hypophosphorous acid, start heating and stir to raise the temperature to 150 ° C for 60 min;

[0024] Raise the temperature to 180°C for 2 hours, then raise the temperature to 210-215°C at 10°C / h and keep the heat until the acid value is less than 12mg KOH / g and the viscosity is greater than 25000 mPa·s (25°C), then cool down;

[0025] When the temperature of the resin is lowered to about 150-160°C, dilute with 360 g of xylene solvent, stir and filter the material to obtain the product.

Embodiment 2

[0027] In a 2000 mL four-necked flask equipped with a stirring device, a thermometer and nitrogen protection, sequentially add 190 g of oleic acid, 50 g of isooctanoic acid, 20 g of isononanoic acid, 80 g of isophthalic acid, 180 g of pentaerythritol, and 30 g of glycerin Alcohol, 60 neopentyl glycol, 200g phthalic anhydride, 1.2g hypophosphorous acid, 30 g xylene, heating and stirring to raise the temperature to 150°C and keep it for 60min; Keep warm at -220°C until the acid value is less than 12mg KOH / g, and the viscosity is greater than 25000 mPa·s (25°C), then cool down;

[0028] When the temperature of the resin is lowered to about 150-160°C, dilute with 340 g of xylene with a solvent, filter and discharge to obtain the product.

Embodiment 3

[0030] In a 2000 mL four-neck flask equipped with a stirring device, a thermometer and nitrogen protection, sequentially add 160 g of oleic acid, 50 g of isooctanoic acid, 50 g of isononanoic acid, 80 g of isophthalic acid, 220 g of pentaerythritol, and 30 g of glycerin Alcohol, 30 neopentyl glycol alcohol, 200 g phthalic anhydride, 30 g xylene, 1.5 g hypophosphorous acid, heated and stirred, and heated to 150 ° C for 60 min;

[0031] Raise the temperature to 180°C for 2 hours, then raise the temperature to 210-215°C at 10°C / h and keep the heat until the acid value is less than 12mg.KOH / g, and the viscosity is greater than 25000 mPa·s (25°C), then cool down;

[0032] When the temperature of the resin is lowered to about 150-160°C, dilute with 350 g of xylene with a solvent, filter and discharge to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com