Quenching process and equipment used in hollow variable-section shaft heads for vehicles

A variable-section, hollow technology, used in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve the problems of uneven hardness, low reliability and fatigue life, and high product manufacturing costs, to prevent quenching deformation and cracks, uniform The effect of high consistency of structure and mechanical properties and product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

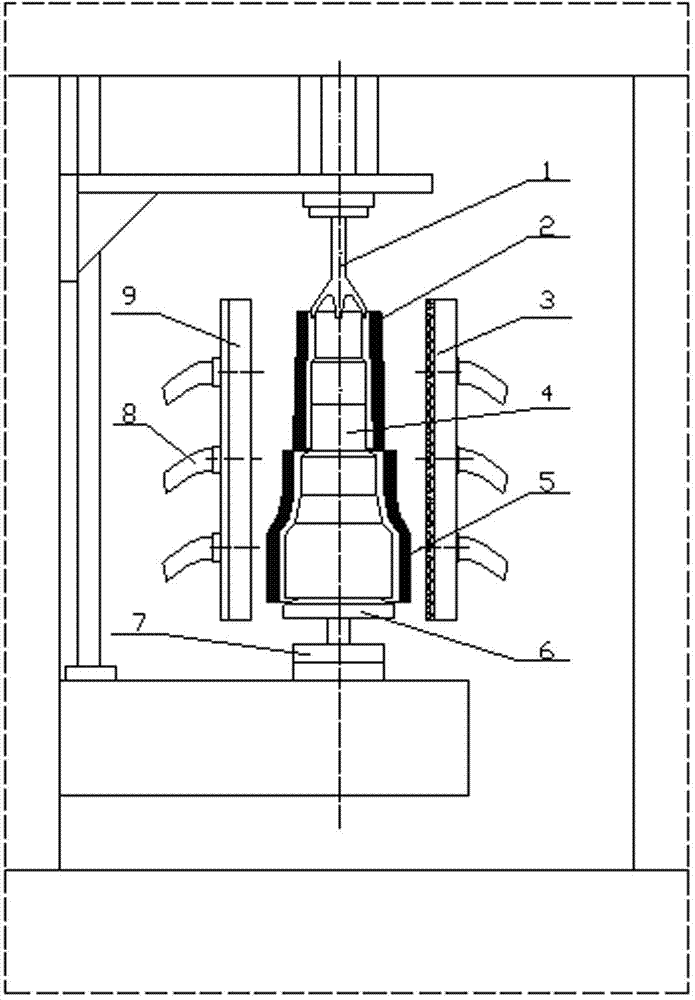

[0027] The quenching process of the present invention applied to the hollow variable-section shaft head for vehicles will be described in detail below in conjunction with the accompanying drawings.

[0028] The present invention is applied to the single-spindle structure CNC induction heating machine tool used in the quenching process of the hollow variable-section shaft head for vehicles. The workpiece 4 is placed, and an induction coil is set on the periphery of the workpiece 4. The induction coil is divided into two parts, which are respectively an induction coil 2 and an induction coil 5. The periphery of the induction coil is provided with water spray plates 3 and 9 with a plurality of water inlet pipes 8, and the workpiece 4 The upper part is provided with an upper top 1 for clamping.

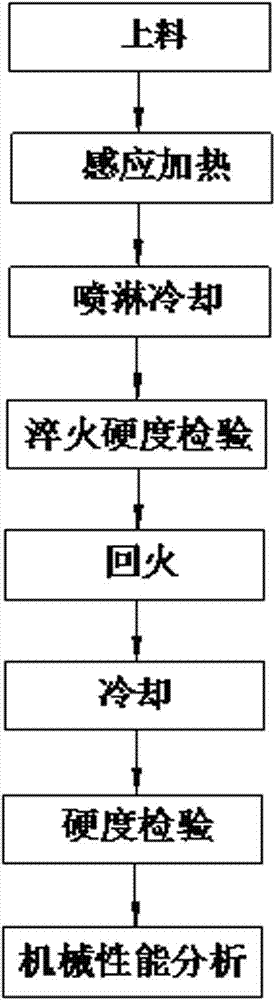

[0029] The present invention is a quenching process applied to a hollow variable-section shaft head for vehicles, which adopts the following process flow:

[0030] Loading - induction he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com