Method of using ferric sulfate solution to perform acid leaching on laterite-nickel ore for extracting nickel and cobalt

A technology of laterite nickel ore and iron sulfate, applied in the direction of improving process efficiency, can solve the problems of high cost, complicated process, low yield, etc., and achieve the effects of prolonging service life, reducing equipment pressure, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

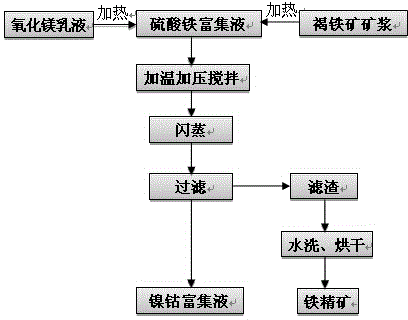

Image

Examples

Embodiment

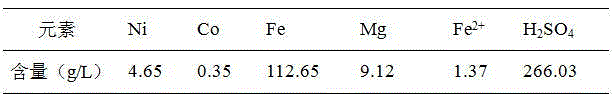

[0024] Sulfate enrichment solution rich in ferric iron: the main components of the atmospheric pressure leaching solution rich in iron, nickel and cobalt used in the experiment are as follows:

[0025] Table 1.1 Main chemical components of atmospheric pressure leachate

[0026]

[0027] Neutralizing raw materials: MgO powder and water are added with water according to the mass ratio of 1:1, fully stirred and mixed to make magnesium oxide emulsion.

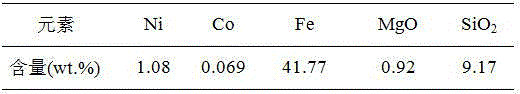

[0028] The raw material composition of limonite-type lateritic nickel ore is shown in Table 1.2;

[0029] Table 1.2 Limonite type lateritic nickel ore raw material composition

[0030]

[0031] Grinding the above-mentioned limonite-type lateritic nickel ore to 200 mesh, adding water and stirring at a solid-to-liquid mass ratio of 1:1 to form a slurry;

[0032] Leaching: Put the iron-rich sulfate enrichment solution (pH ≈ 0.8,) and limonite slurry into the autoclave at the same time at a ratio of 1:2, heat to 95°C, and stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com