A trench mosfet structure and method of making the same

A manufacturing method and trench technology, which are applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of low withstand voltage capacity in the terminal area, increase the degree of depletion, improve the withstand voltage capacity, and improve The effect of pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

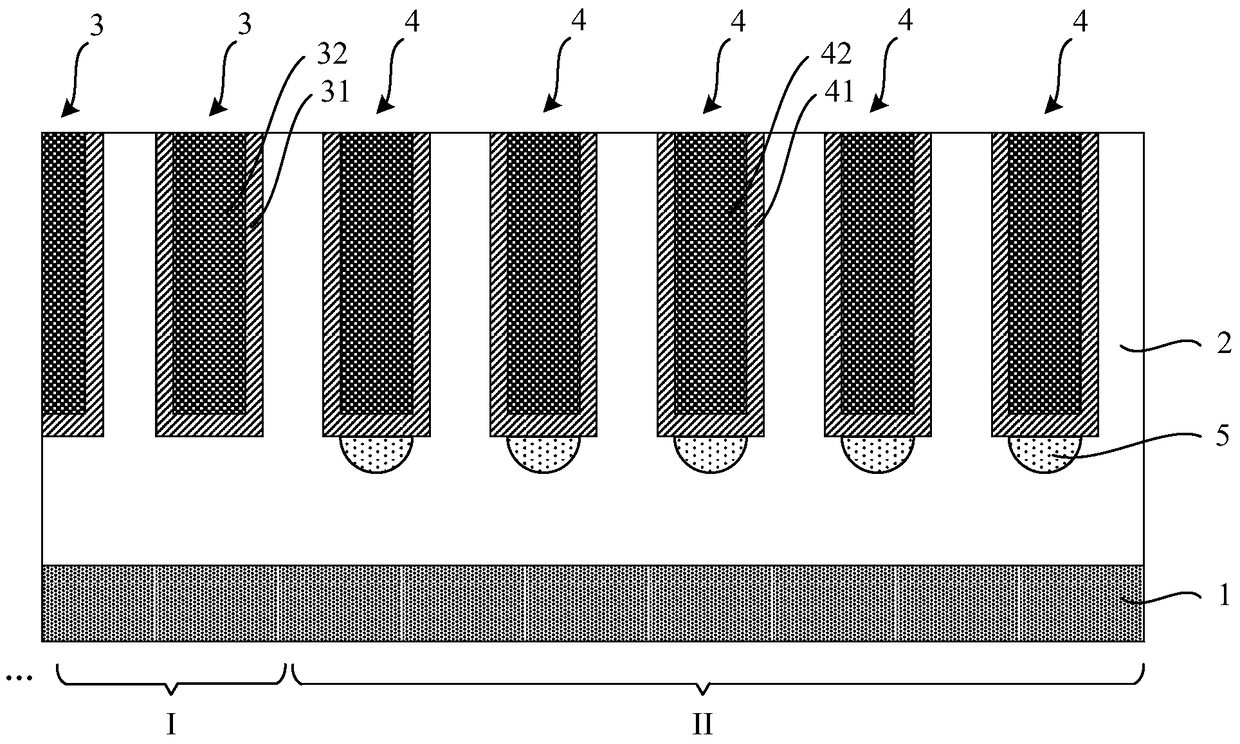

[0052] The present invention provides a trench MOSFET structure, please refer to figure 1, showing a cross-sectional view of the structure, including an N-type heavily doped substrate 1 and an N-type lightly doped epitaxial layer 2 formed on the N-type heavily doped substrate 1; the N-type lightly doped epitaxial layer Several trench structures 3 in the cell region and several trench structures 4 in the termination region are formed in 2, wherein at least one trench structure 4 in the termination region is connected to a P-type doped structure 5 at its bottom.

[0053] The cell region trench structure 3 is located in the cell region I of the trench MOSFET structure, and the termination region trench structure 4 is located in the termination region II of the trench MOSFET structure.

[0054] Specifically, the N-type heavily doped substrate 1 serves as the drain region of the trench MOSFET structure, and the N-type lightly doped epitaxial layer 2 serves as the drift region of th...

Embodiment 2

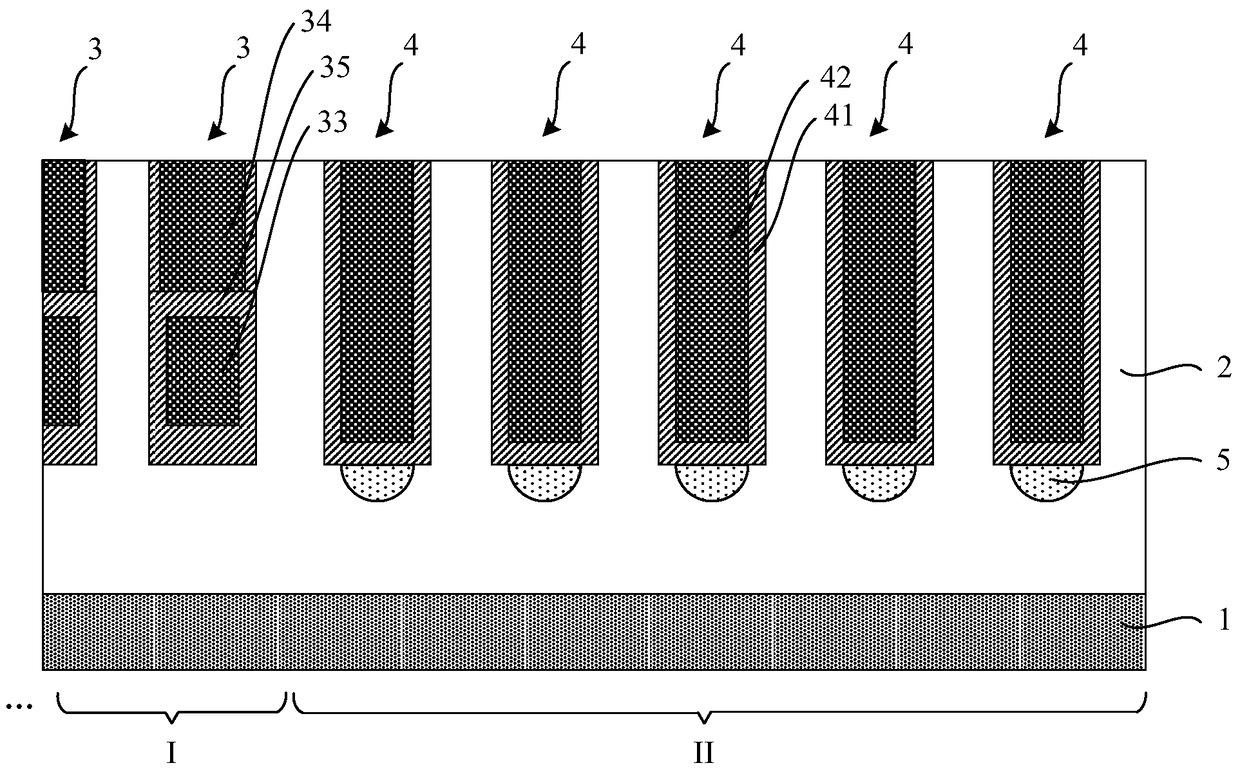

[0060] This embodiment adopts basically the same technical solution as Embodiment 1, the difference is that in Embodiment 1, the trench structure in the cell area adopts a conventional trench gate structure, while in this embodiment, the trench structure in the cell area The structure adopts the split gate structure.

[0061] see figure 2 , showing a cross-sectional view of a trench MOSFET structure in this embodiment, including an N-type heavily doped substrate 1 and an N-type lightly doped epitaxial layer 2 formed on the N-type heavily doped substrate 1; the N A plurality of cell region trench structures 3 and a plurality of termination region trench structures 4 are formed in the lightly doped epitaxial layer 2, wherein at least one termination region trench structure 4 is connected to a P-type doping structure 5 at its bottom.

[0062] Such as figure 2 As shown, the cell region trench structure 3 is a split gate, including a shielding gate 33 and a control gate 34 form...

Embodiment 3

[0066] A kind of fabrication method of trench MOSFET structure of the present invention is as follows, at least comprises the following steps:

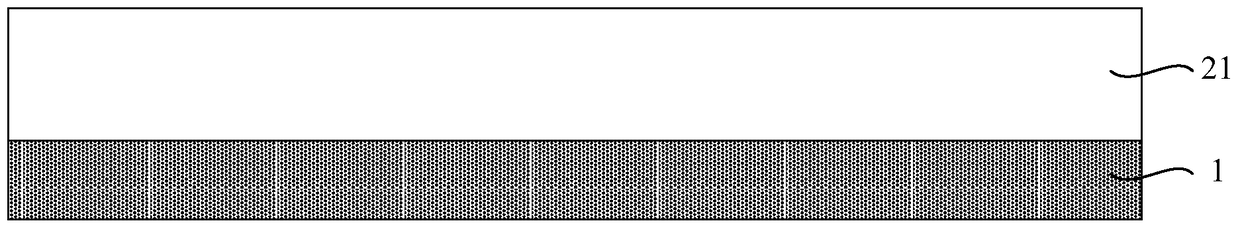

[0067] See first image 3 , performing step S1: providing an N-type heavily doped substrate 1 , and epitaxially first N-type lightly doped layer 21 on the N-type heavily doped substrate 1 .

[0068] The N-type heavily doped substrate 1 serves as the drain region of the trench MOSFET structure, and the N-type lightly doped epitaxial layer 1 serves as a part of the drift region of the trench MOSFET structure.

[0069] then see Figure 4 and Figure 5 , perform step S2: perform P-type ion implantation, and form at least one P-type doped structure 5 on the upper part of the first N lightly doped layer 21; corresponding to the location.

[0070] Specifically, such as Figure 4 As shown, firstly a mask layer 6 is formed on the surface of the first N-type lightly doped layer 21, and at least one opening 7 is formed in the mask layer 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com