Synchronous motor and power system for extended-range electric vehicles

A technology for synchronous motors and electric vehicles, applied to electric vehicles, engine-driven traction, motors, etc., can solve the problems of unsuitable working environment, low maximum speed, weak anti-vibration ability, etc., to save space in the engine compartment, Reduced volume and good vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

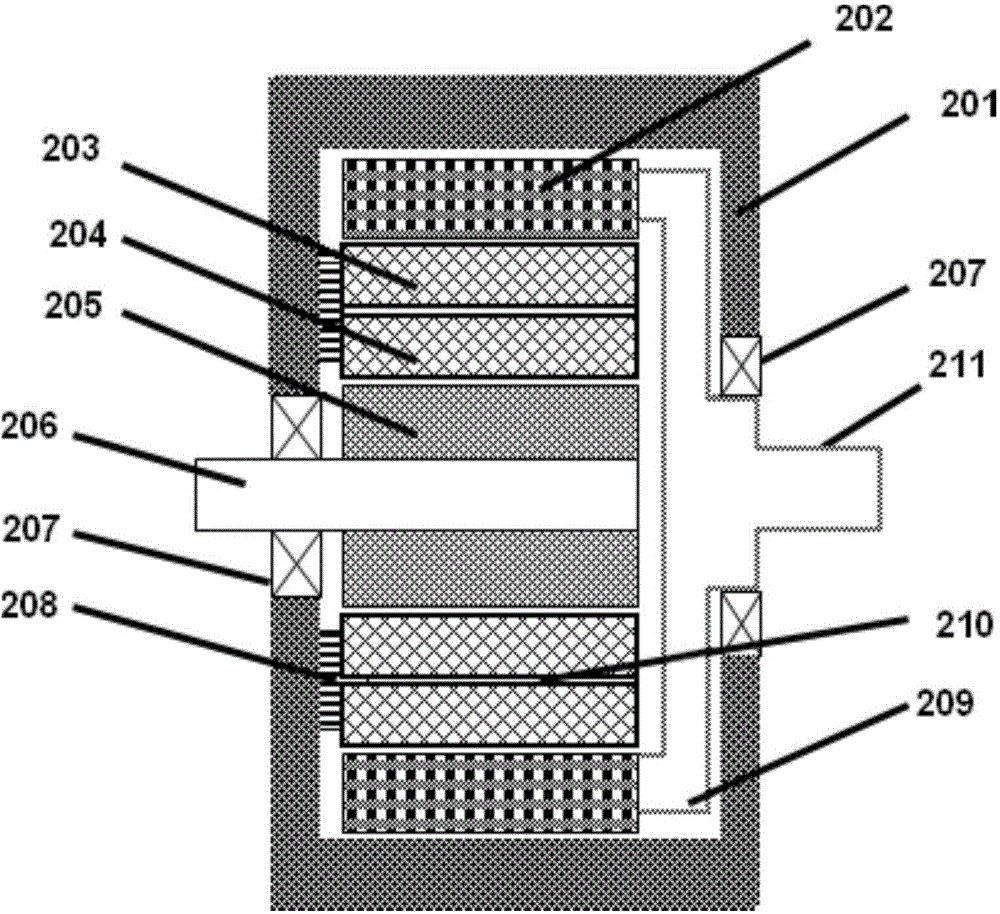

[0037] see image 3 , which is an embodiment of the present application for a synchronous motor for an extended-range electric vehicle. The casing 201 encloses an inner cavity, and an outer rotor 202 , a first stator 203 , a second stator 204 and an inner rotor 205 are arranged in the inner cavity. The housing is, for example, made of cast aluminum. The first stator 203 and the second stator 204 are fixed on the housing 201 by fixing bolts 208 . The first stator 203 surrounds the second stator 204 with a certain gap between them, and the cooling water channel 210 is disposed in the gap. The outer rotor is rotatably disposed on the periphery of the first stator 203, which is a permanent magnet component. The inner rotor 205 is rotatably provided inside the second stator 204, which is an electrically exciting part. The motor input shaft 206 is rotatably fixed to the casing 201 through the bearing 207 , and the motor output shaft 211 is also rotatably fixed to the casing 201 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com