Injection molding anisotropic bone substitute composite material and preparation method thereof

A composite material and injection molding technology, applied in medical science, prosthesis, etc., can solve problems such as limited effects, and achieve the effect of improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

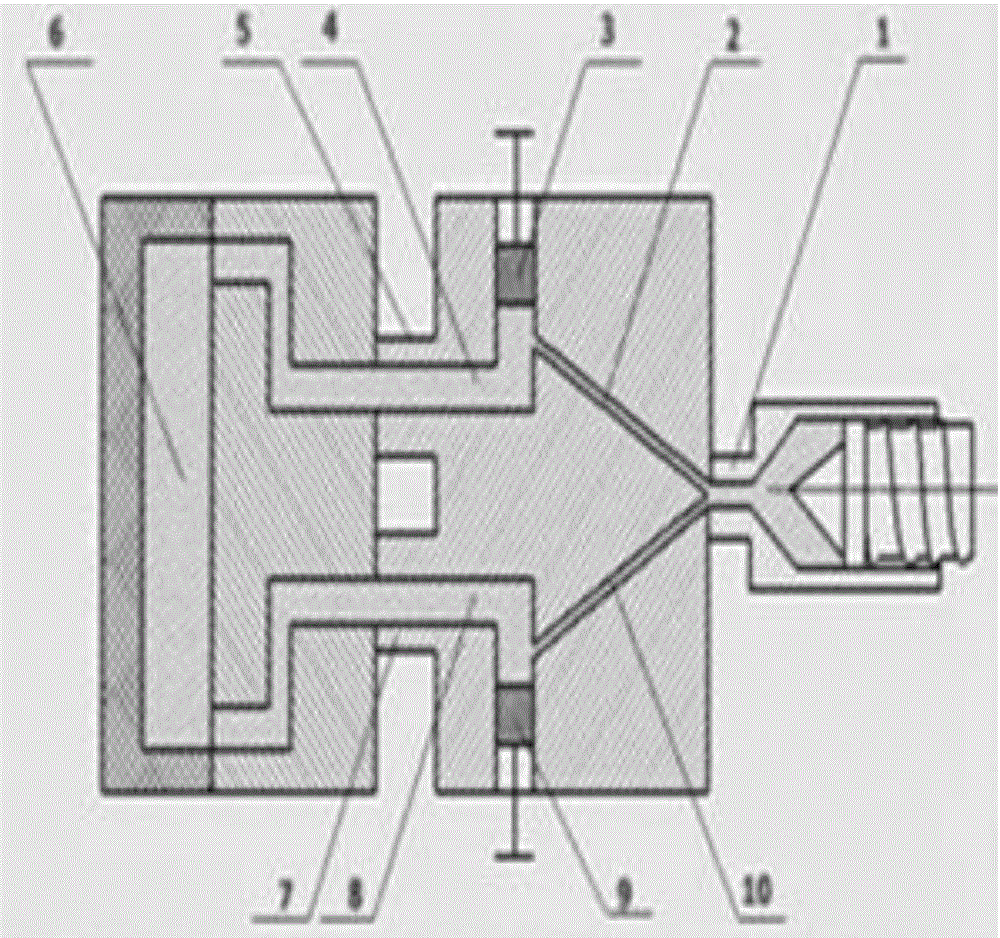

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of pure HDPE extruded pellets: put pure HDPE in a twin-screw extruder to melt and extrude, and the extruder conveys the compression section, and the temperatures of the melting section and the metering section are set to 170°C and 200°C, respectively. 190°C, the speed of the main engine is set at 120 rpm, and the speed of the feeding screw is 4 rpm, then the extruded product is forced to cool and pelletized, and dried at 90°C for 10 hours until the water content is not higher than 0.01% of its own weight;

[0034] (2) Vibration injection molding: Vibration injection molding is performed on the above-mentioned dried extruded pellets. The barrel and nozzle temperatures of the injection molding machine are set at 180°C and 190°C respectively, the temperature of the hot runner is set at 180°C, and the mold temperature is set at 180°C. It is set at 30°C, and the holding pressures of the three stages are set at 0, 25, and 35 MPa respectively.

Embodiment 2

[0036] (1) Preparation of 5wt% HA / HDPE mechanical mixture: 5% HA and 95% HDPE were mechanically mixed with a high mixer for 20 minutes to make them evenly mixed.

[0037] (2) Preparation of 5wt% HA / HDPE melt mixture: the above mixture is placed in a twin-screw extruder for melt extrusion, and the extruder conveys the compression section, and the temperatures of the melting section and the metering section are respectively set to 170°C and 200°C, 190°C, the speed of the main engine is set at 120 rpm, and the speed of the feeding screw is 4 rpm, then the mixture is forced to cool and granulate, and dried under vacuum at 90°C until the water content is not higher than its own weight. 0.01% made extruded material;

[0038] (3) Vibration injection molding: Vibration injection molding is performed on the above dried extruded pellets. The barrel and nozzle temperatures of the injection molding machine were set to 170°C and 180°C respectively, the temperature of the hot runner was se...

Embodiment 3

[0040] (1) Preparation of 10wt% HA / HDPE mechanical mixture: 10% HA and 90% HDPE were mechanically mixed with a high mixer for 20 minutes to make them evenly mixed.

[0041] (2) Preparation of 10wt% HA / HDPE melt mixture: the above mixture is placed in a twin-screw extruder for melt extrusion, and the extruder conveys the compression section, and the temperatures of the melting section and the metering section are respectively set to 170°C and 200°C, 190°C, the speed of the main engine is set at 120 rpm, and the speed of the feeding screw is 4 rpm, then the mixture is forced to cool and granulate, and dried under vacuum at 90°C until the water content is not higher than 0.01 of its own weight % obtained extruded material;

[0042] (3) Vibration injection molding: Vibration injection molding is performed on the above dried extruded pellets. The barrel and nozzle temperatures of the injection molding machine were set to 180°C and 180°C respectively, the temperature of the hot run...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com