Processing method for automatic dosing system

A technology of automatic dosing and processing methods, which is applied to metal processing equipment, metal processing machinery parts, maintenance and safety accessories, etc., and can solve problems such as time-consuming and cost-consuming, reduced ability of cooling and flushing cutting, poor work efficiency, etc. , to achieve the effect of saving man-hours and costs and maintaining concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to achieve the above-mentioned purpose and effect, the technical means and the structure adopted by the present invention are hereby illustrated in detail with respect to the preferred embodiments of the present invention. The structure and function are as follows to facilitate a complete understanding.

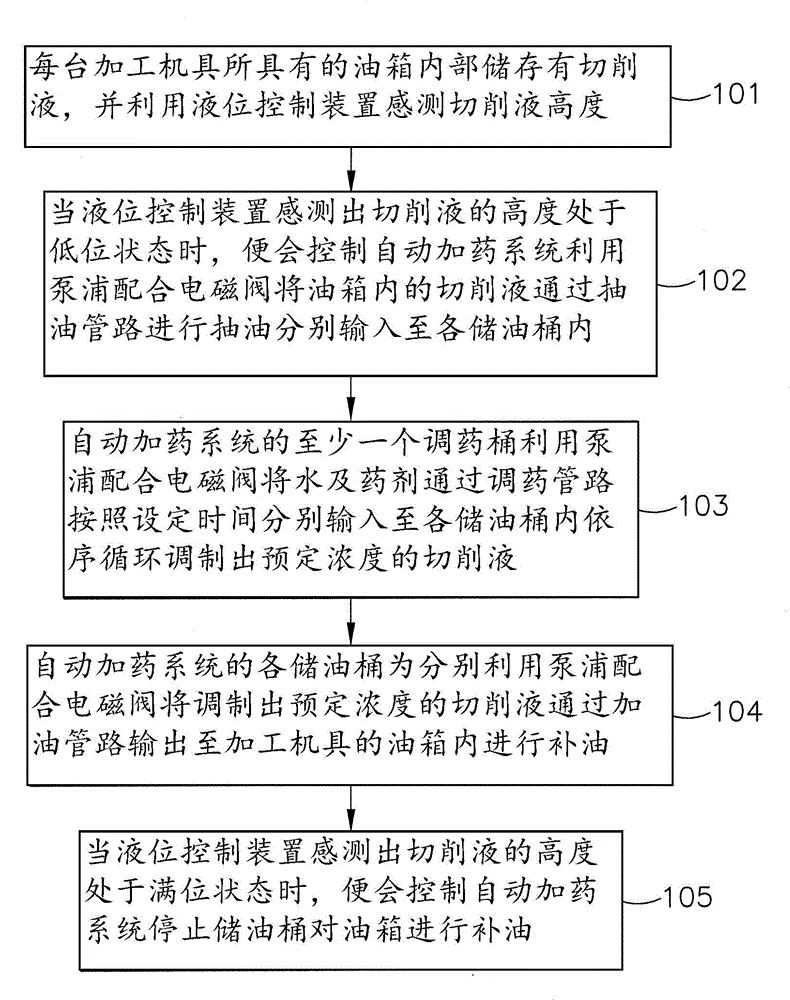

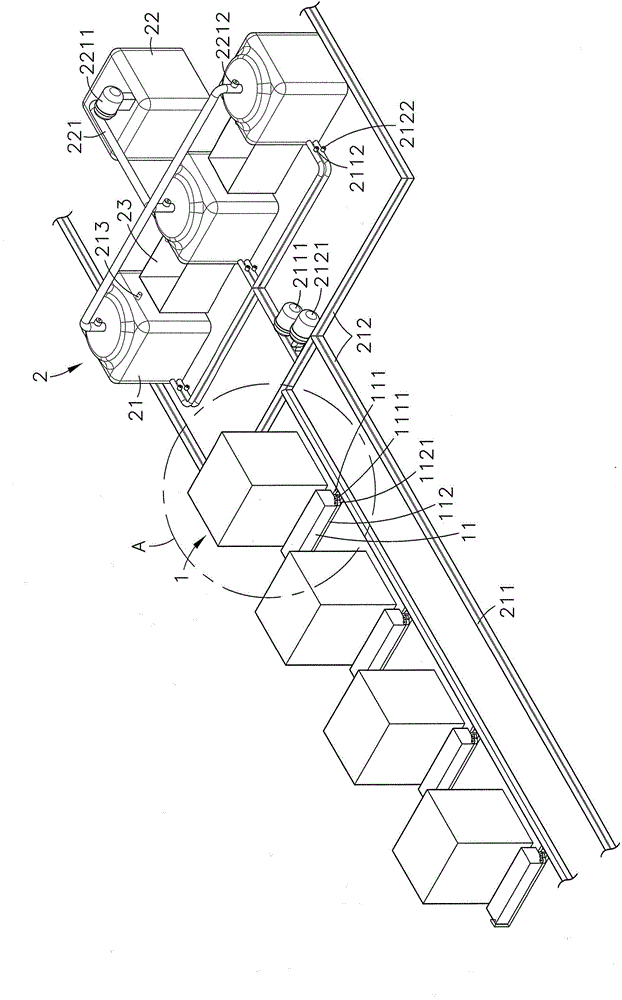

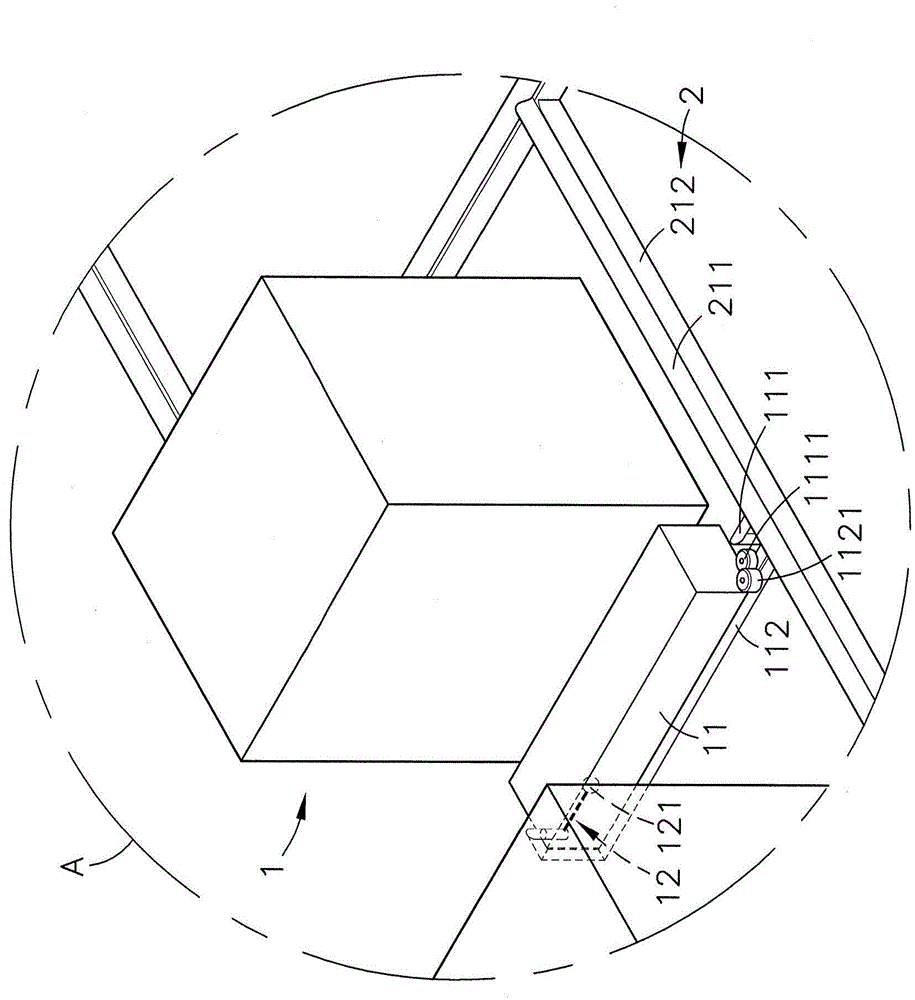

[0032] see figure 1 , figure 2 , image 3 Shown, respectively is the step flowchart of the present invention, the three-dimensional appearance figure of preferred embodiment and image 3 It can be seen clearly from the figure that the present invention includes a processing tool 1 and an automatic dosing system 2, so the main components and features of this case are described in detail as follows, wherein:

[0033] The processing tool 1 can be a lathe, a milling machine, a planer, a drilling machine, a numerical control machine tool (NC), a computer numerical control machine tool (CNC) or other processing machine tools for various processing, and the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com