Ultrahigh pressure water jet-based compressor housing opening and disassembling equipment and control method of equipment

A compressor and ultra-high pressure technology, which is applied in the field of compressor shell opening and dismantling equipment and its control, can solve the problems of affecting the shell opening operation, burning out electrodes, and fast wear of the grinding wheel, so as to improve the shell opening efficiency and fast tool setting Accurate, efficient effect of shell opening operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

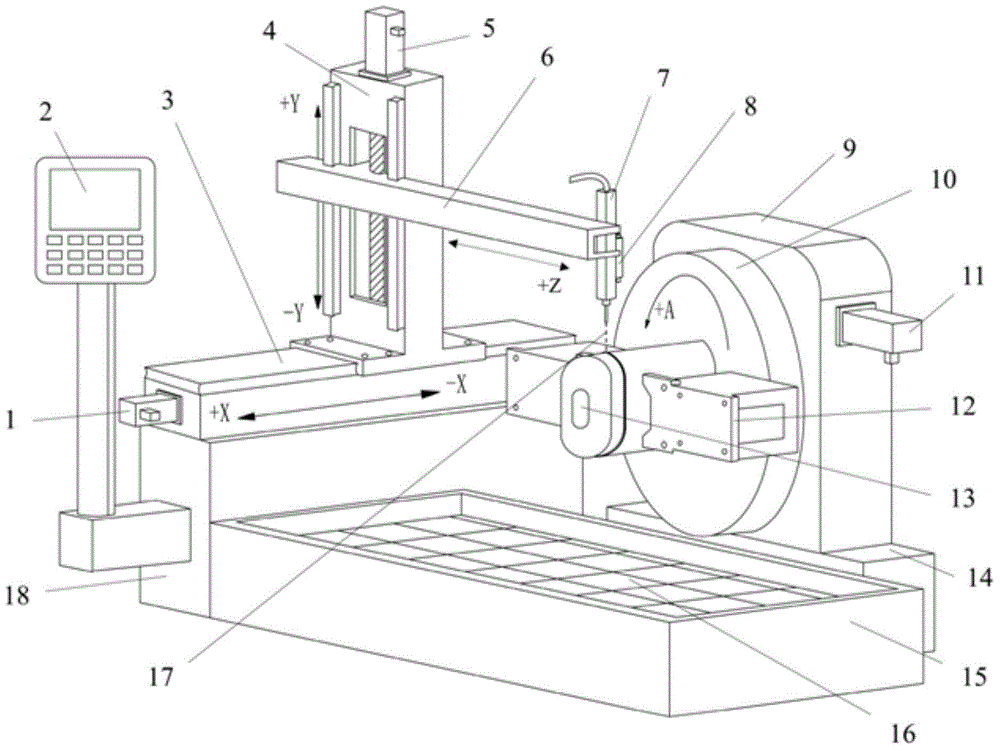

[0031] In this embodiment, the structural form of the compressor shell opening and dismantling equipment based on ultra-high pressure water jet is:

[0032] Such as figure 1As shown, a first horizontal base 14 and a second horizontal base 18 are respectively provided on adjacent two sides of a horizontally arranged rectangular sump 15; a turntable is set on the first horizontal base 14, and the turntable includes a vertical The turntable base 9 on the first horizontal base 14, and the turntable base 9 that is arranged on the turntable base 9, towards the side where the rectangular sump 15 is, the turntable layer 10 that can turn in the vertical plane, on the turntable layer 10 Fixture 12 is set, and the compressor 13 to be disassembled is horizontally clamped on the fixture 12, and the rotary servo motor 11 drives the compressor 13 to rotate through the rotary layer 10, and the rotary axis of the rotary layer 10 coincides with the compressor 13; A worktable that can move in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com