Constant-tension adhesive tape rewinder allowing tape roll discharging position to be controlled

A rewinding machine and constant tension technology, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of rewinding processing requirements of polytetrafluoroethylene tapes, deformation of cylindrical tapes, and low production efficiency and other problems, to achieve the effect of small stress, smooth tape and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The constant tension adhesive tape rewinder with controllable unwinding position of this embodiment is formed as follows:

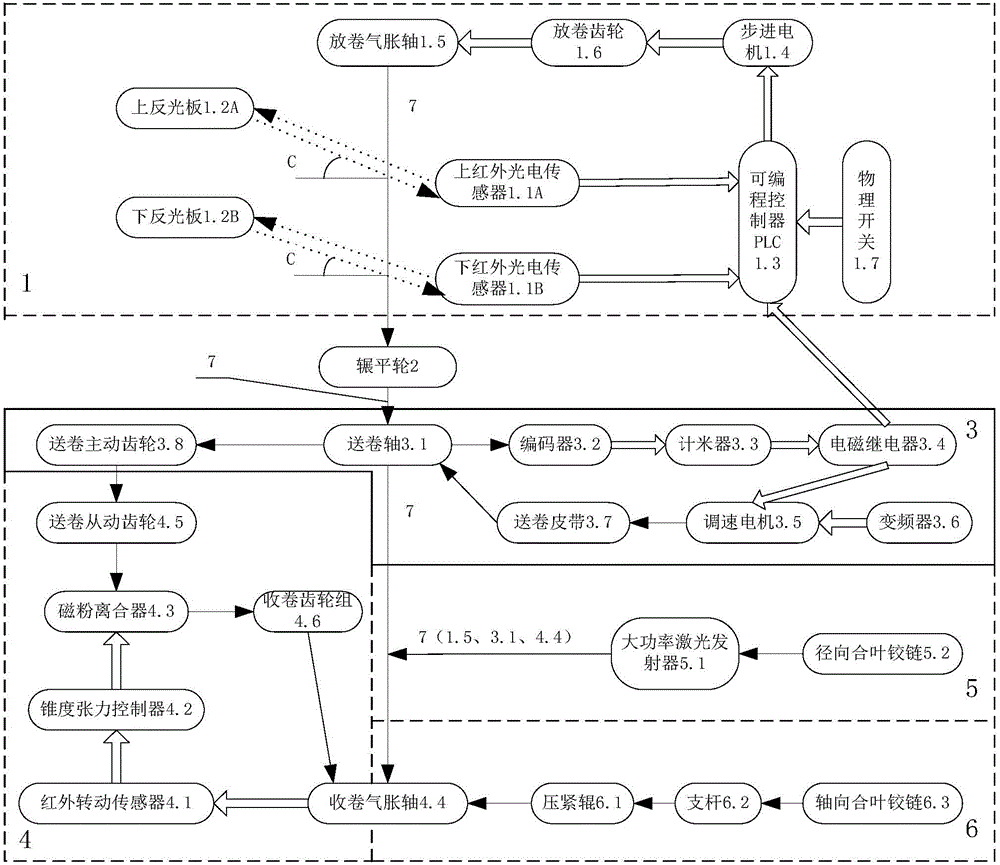

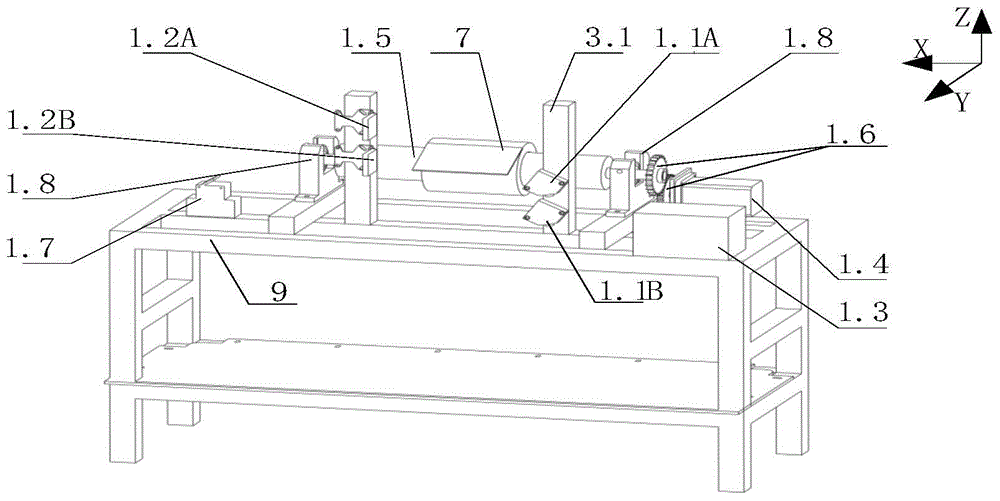

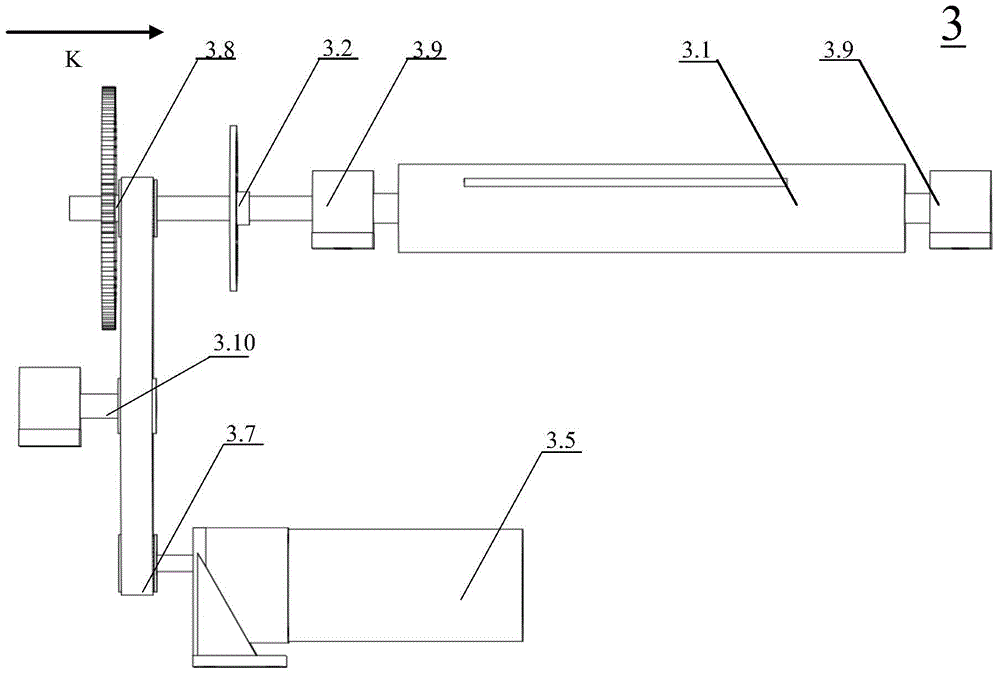

[0019] See Image 6 , on the frame 9, at the unwinding end, there is an unwinding air shaft 1.5 supported on the unwinding simply supported beam with tape 7 rolled on it. At the rewinding end, a rewinding inflatable shaft 4.4 supported on a rewinding simply supported beam is provided with an adhesive tape 7 . See figure 1 , between the unwinding air shaft 1.5 and the winding air shaft 4.4 are provided with: double closed-loop unwinding position control system 1; flattening wheel 2; sending reel 3.1 and winding length control system 3; semi-closed loop at the rewinding end Tension control system 4, deviation correcting device 5, pressing assembly 6. In order to ensure the strength of the frame, 4040 European standard heavy-duty industrial aluminum profiles and special connectors and adjustment parts can be used in actual production.

[0020] 1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com