Method for preparing indium oxide octahedral nanocrystal film

A technology of octahedron and nanocrystal, applied in the field of preparing indium oxide octahedral nanocrystal film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] InCl 3 4H 2 O is indium salt, and the glass plate is the substrate:

[0020] (1) Make a mixed solution of ethylene glycol, water, absolute ethanol, and glacial acetic acid at a volume ratio of 2:3:5:12, and then add InCl 3 4H 2 O is dissolved in it to form an indium ion concentration of 1.20 mol L -1 solution, and stirred rapidly at room temperature for 2 h;

[0021] (2) Add citric acid to the solution described in (1), stir and dissolve, and the concentration of citric acid is 0.30 mol L -1 ;

[0022] (3) Heating the solution described in (2) to 50°C, stirring at this temperature for 5 h, and cooling to obtain a sol;

[0023] (4) Put 2 drops of the sol described in (3) onto a clean 2 × 2 cm 2 On the substrate, the film was coated by spin-coating process at a speed of 3000 rpm for 40 seconds, and the obtained film was dried at 100°C for 2 h to obtain a gel film;

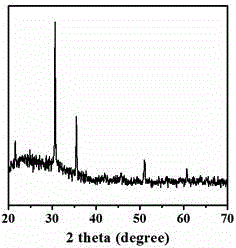

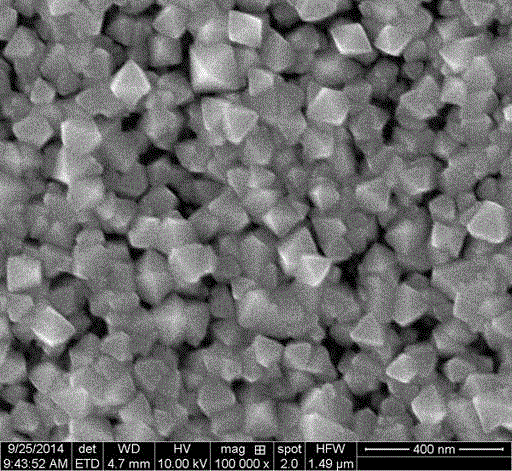

[0024] (5) Sintering the gel film described in (4) at 500°C to obtain an indium oxide octahedral na...

Embodiment 2

[0027] InCl 3 4H 2 O is indium salt, and the glass plate is the substrate:

[0028] (1) Make a mixed solution of ethylene glycol, water, absolute ethanol, and glacial acetic acid in a volume ratio of 3:0:5:12, and then add InCl 3 4H 2 O is dissolved in it to form an indium ion concentration of 1.00 mol L -1 solution, and stirred rapidly at room temperature for 2 h;

[0029] (2) Add citric acid to the solution described in (1), stir and dissolve, and the concentration of citric acid is 0.10 mol L -1 ;

[0030] (3) Heating the solution described in (2) to 40°C, stirring at this temperature for 3 h, and cooling to obtain a sol;

[0031] (4) Put 2 drops of the sol described in (3) onto a clean 2 × 2 cm 2 On the substrate, the film was coated by spin-coating process at a speed of 3000 rpm for 40 seconds, and the obtained film was dried at 100°C for 2 h to obtain a gel film;

[0032] (5) Sintering the gel film described in (4) at 500°C to obtain an indium oxide octahedral na...

Embodiment 3

[0035] InCl 3 4H 2 O is indium salt, and FTO conductive glass is the substrate:

[0036] (1) Make a mixed solution of ethylene glycol, water, absolute ethanol, and glacial acetic acid in a volume ratio of 2:3:5:15, and then add InCl 3 4H 2 O is dissolved in it to form an indium ion concentration of 2.20 mol L -1 solution, and stirred rapidly at room temperature for 2 h;

[0037] (2) Add citric acid to the solution described in (1), stir and dissolve, and the concentration of citric acid is 0.10 mol L -1 ;

[0038] (3) Heating the solution described in (2) to 40°C, stirring at this temperature for 3 h, and cooling to obtain a sol;

[0039](4) Put 2 drops of the sol described in (3) onto a clean 2 × 2 cm 2 On the substrate, the film was coated by spin-coating process at a speed of 3000 rpm for 40 seconds, and the obtained film was dried at 100°C for 2 h to obtain a gel film;

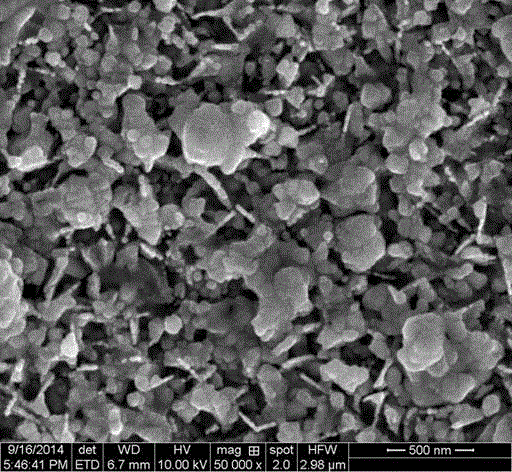

[0040] (5) Sintering the gel film described in (4) at 500°C to obtain an indium oxide octahedra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com