Recycled aggregate ecological water permeable brick and production method thereof

A technology of recycled aggregate and production method, which is applied in the field of building material concrete, which can solve the problems of groundwater circulation damage, lack of water permeability function, poor environmental protection function, etc., and achieve high water permeability, increase product added value, and high water retention rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

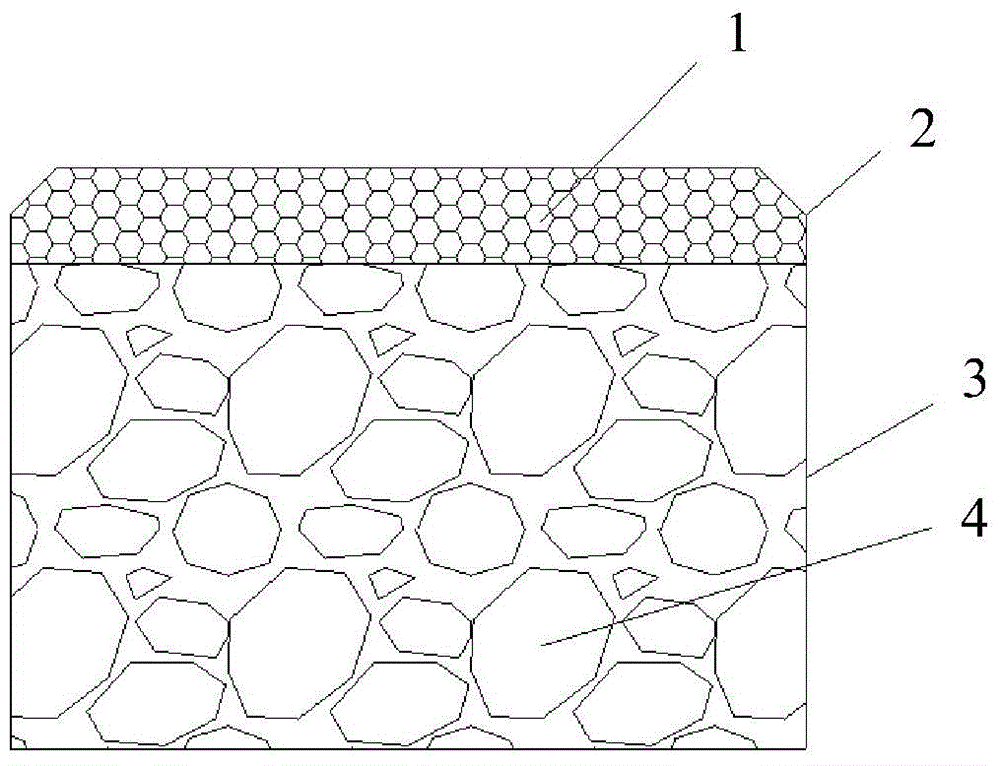

[0023] see figure 1 , in an embodiment of the present invention, a recycled aggregate ecological permeable brick includes 300-500 parts by weight of base material, 50-80 parts of fabric, and 1000-1400 parts of water; the base material includes 300-500 parts by weight of base material 200-445 parts of recycled aggregate, 50-90 parts of gel material, and 5-10 parts of admixture; recycled aggregate is single-grained aggregate with a particle size of 4-12mm made from construction waste; gel The materials include 39-82 parts by weight of cement, 5-8 parts of lime, and 3-5 parts of fly ash; the admixtures include 3-6 parts by weight of polycarboxylate water reducer and 2-4 parts of rubber powder Parts; the fabric is one or a combination of quartz sand, river sand, recycled sand and machine-made sand with a particle size of 10-14 mesh.

[0024] In the step of grading the recycled aggregate, the recycled aggregate is sieved into single-grain grade aggregate with a particle size of 4-...

Embodiment 2

[0034] see figure 1 , in the embodiment of the present invention, a recycled aggregate ecological permeable brick includes 300 parts by weight of base material, 50 parts of fabric, and 1000 parts of water; the base material includes 200 parts by weight of recycled aggregate , 90 parts of gel material, 10 parts of admixture; the recycled aggregate is a single-grained aggregate with a particle size of 4-6mm made from construction waste; the gel material includes 82 parts by weight of cement, lime 5 parts, 3 parts of fly ash, additives include 6 parts by weight of polycarboxylate superplasticizer, 4 parts of rubber powder; the fabric is one of quartz sand, river sand, recycled sand and machine-made sand with a particle size of 10 mesh or a combination thereof.

[0035] The production method of recycled aggregate ecological permeable bricks, the specific steps are as follows:

[0036] Classification of recycled aggregates: multiple screening of recycled aggregates, and screening...

Embodiment 3

[0045] see figure 1, in the embodiment of the present invention, a recycled aggregate ecological permeable brick includes 400 parts by weight of base material, 65 parts of fabric, and 1200 parts of water; the base material includes 330 parts by weight of recycled aggregate , 62 parts of gel material, 8 parts of admixture; the recycled aggregate is a single-grained aggregate with a particle size of 6-8mm made from construction waste; the gel material includes 52 parts of cement, lime 6 parts, 4 parts of fly ash, additives include 5 parts by weight of polycarboxylate superplasticizer, 3 parts of rubber powder; the fabric is one of quartz sand, river sand, recycled sand and machine-made sand with a particle size of 12 mesh or a combination thereof.

[0046] The production method of recycled aggregate ecological permeable bricks, the specific steps are as follows:

[0047] Classification of recycled aggregates: multiple screening of recycled aggregates, and screening of recycled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com