Method for removing chlorophyll in microalgaes

A chlorophyll and removal technology is applied in the field of chlorophyll removal to achieve the effects of simplifying the process, improving the decolorization efficiency and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

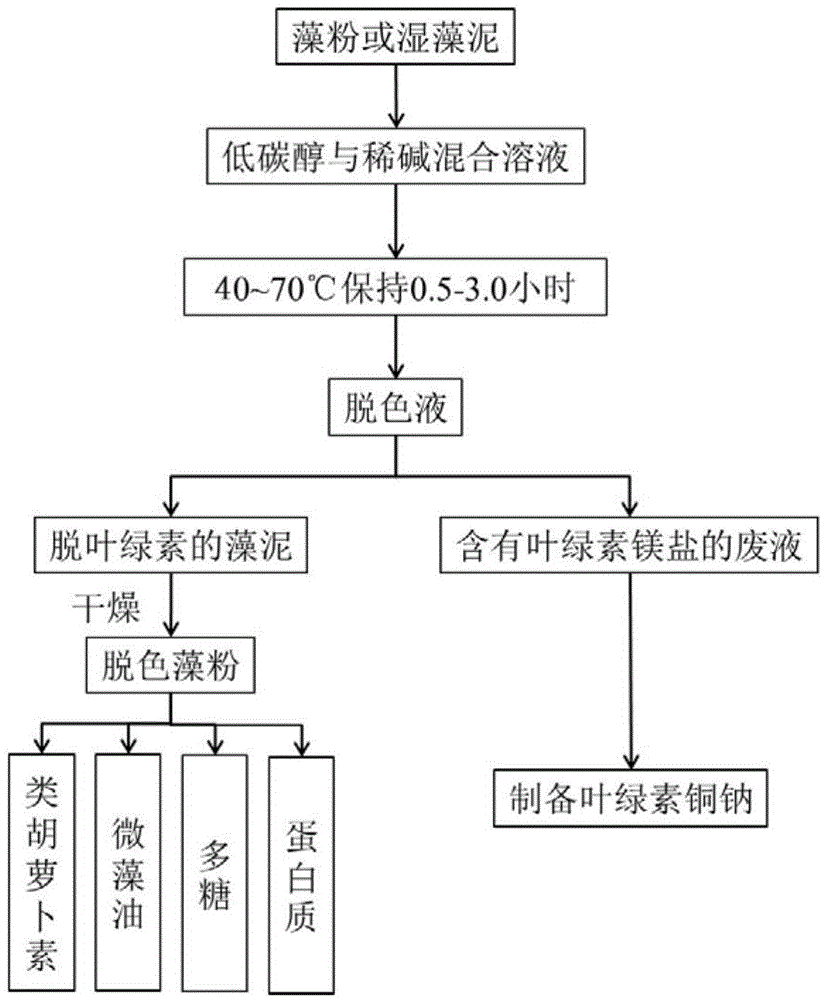

Embodiment 1

[0030] A kind of green algae was selected to study the chlorophyll removal process. Through measurement, it is found that the chlorophyll content of the algae powder is 0.48g / 100g-1.20g / 100g, the algae powder before decolorization is yellow-green or green, and the algae oil is dark brown or black. Optimal decolorization conditions were obtained through process parameter optimization: the decolorization solution was obtained by mixing 100% ethanol with 1% to 2% sodium hydroxide solution according to the volume ratio of 1:4, and then the green algae powder According to the material concentration of 1% to 2%, it is mixed with the decolorizing solution and reacted at 70° C. for 1.0 to 2.0 hours to remove the chlorophyll from the algae powder.

[0031] By the method of this embodiment, the removal rate of chlorophyll is more than 90%, the algae powder after decolorization becomes orange-red or gray-yellow, the extracted microalgae oil is transparent orange-red or slightly yellow, a...

Embodiment 2

[0034] A diatom was chosen to study the chlorophyll removal process. It is found by measuring that the chlorophyll content of the algae powder is 0.32g / 100g, and the algae powder before decolorization is dark brown. Mix ethanol with a concentration of 100% and a sodium hydroxide solution with a concentration of 0.5% according to a volume ratio of 1:10 or 1:5 to obtain a decolorizing solution, and then diatom algae powder is mixed with the decolorizing solution according to a material concentration of 0.5%. React at 40°C for 3.0 hours to remove chlorophyll from the algae powder.

[0035] Through the method of this embodiment, the removal rate of chlorophyll can reach more than 90%.

[0036] The decolorized waste liquid in this example can be used for the preparation of sodium copper chlorophyllin, the diatom powder of chlorophyll can be used for the extraction and preparation of microalgae oil, protein, polysaccharide and carotenoid, and the diatom powder of chlorophyll can be...

Embodiment 3

[0038] A species of Eurythmia euphratus was chosen to study the chlorophyll removal process. The algae powder before decolorization is green or yellow-green, and the algae oil is dark brown. Mix ethanol with a concentration of 100% and potassium hydroxide solution with a concentration of 2% according to the volume ratio of 1:4 to obtain a decolorizing solution, and then mix the algae powder with the decolorizing solution according to the material concentration of 1% to 5%. , react at 70°C for 1 to 2 hours to remove chlorophyll from the algae powder.

[0039] By the method of this embodiment, the removal rate of chlorophyll can exceed 95%, the algae flour after degreening becomes pale yellow or orange, the microalgae oil becomes yellow or transparent orange, and the neutral lipid ratio of microalgae oil increases , the ratio of glycolipids and phospholipids is reduced.

[0040] The decolorization waste liquid in this example can be used for the preparation of sodium copper ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com