Method for preparing regenerated rubber

A technology of regenerated rubber and rubber powder, which is applied in the direction of plastic recycling and recycling technology, which can solve the problems of time-consuming production process of reclaimed rubber, and achieve the effects of low action temperature, excellent performance and good desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

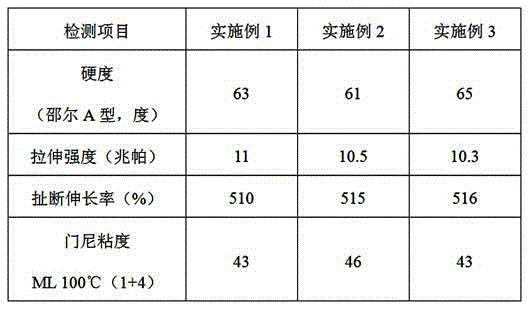

Examples

Embodiment 1

[0019] The preparation method of the present embodiment regenerated rubber comprises the following steps:

[0020] A, prepare rubber powder: clean 1 kilogram of waste rubber, dry, cut glue, pulverize, cross 100 mesh molecular sieves, obtain 0.85 kilogram of rubber powder;

[0021] B. Preparation of desulfurizer: Mix 7 grams of N-methyldiethanolamine and 8 grams of toluene evenly, then add 8 grams of iron oxide, heat up to 35° C., and keep warm for 13 minutes to obtain a desulfurizer;

[0022] C. Desulfurization regeneration: transfer the rubber powder into the ultrasonic extractor, then add desulfurizer and 5 grams of coumarone drop by drop, stir evenly, adjust the ultrasonic power to 800 watts, control the temperature to 30°C, and react for 5 minutes; then heat up to 60°C, react for 6 minutes;

[0023] D. Tablet compression: After the reaction in step C is complete, the resulting product is compressed into tablets to obtain reclaimed rubber.

Embodiment 2

[0025] The preparation method of the present embodiment regenerated rubber comprises the following steps:

[0026] A, prepare rubber powder: clean 10 kilograms of waste rubber, dry, cut glue, pulverize, cross 100 mesh molecular sieves, obtain 8.6 kilograms of rubber powder;

[0027] B. Preparation of desulfurizer: Mix 80 grams of N-methyldiethanolamine and 120 grams of xylene evenly, then add 160 g of iron oxide, heat up to 42° C., and keep warm for 9 minutes to obtain a desulfurizer;

[0028] C. Desulfurization regeneration: transfer the rubber powder into the ultrasonic extractor, then add desulfurizer and 175 grams of rosin drop by drop, stir evenly, adjust the ultrasonic power to 600 watts, control the temperature to 45°C, and react for 2 minutes; then heat up to 70 ℃, react for 3 minutes;

[0029] D. Tablet compression: After the reaction in step C is complete, the resulting product is compressed into tablets to obtain reclaimed rubber.

Embodiment 3

[0031] The preparation method of the present embodiment regenerated rubber comprises the following steps:

[0032] A, prepare rubber powder: clean 50 kilograms of waste rubber, dry, cut glue, pulverize, cross 100 mesh molecular sieves, obtain 48.2 kilograms of rubber powder;

[0033] B. Preparation of desulfurizer: Mix 200 grams of N-methyldiethanolamine and 500 grams of benzene evenly, then add 300 grams of iron oxide, heat up to 50° C., and keep warm for 6 minutes to obtain a desulfurizer;

[0034] C. Desulfurization regeneration: transfer the rubber powder into the ultrasonic extractor, then add desulfurizer and 960 grams of fatty acid drop by drop, stir evenly, adjust the ultrasonic power to 400 watts, control the temperature to 60°C, and react for 3.5 minutes; then raise the temperature to 80 ℃, react for 1 minute;

[0035] D. Tablet compression: After the reaction in step C is complete, the resulting product is compressed into tablets to obtain reclaimed rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com