Polypropylene porous membrane and preparation method thereof

A polypropylene and porous film technology, applied in the field of polypropylene porous film and its preparation, can solve the problems of poor performance of polypropylene porous film, difficult processing and molding, etc., and achieve the effect of promoting solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

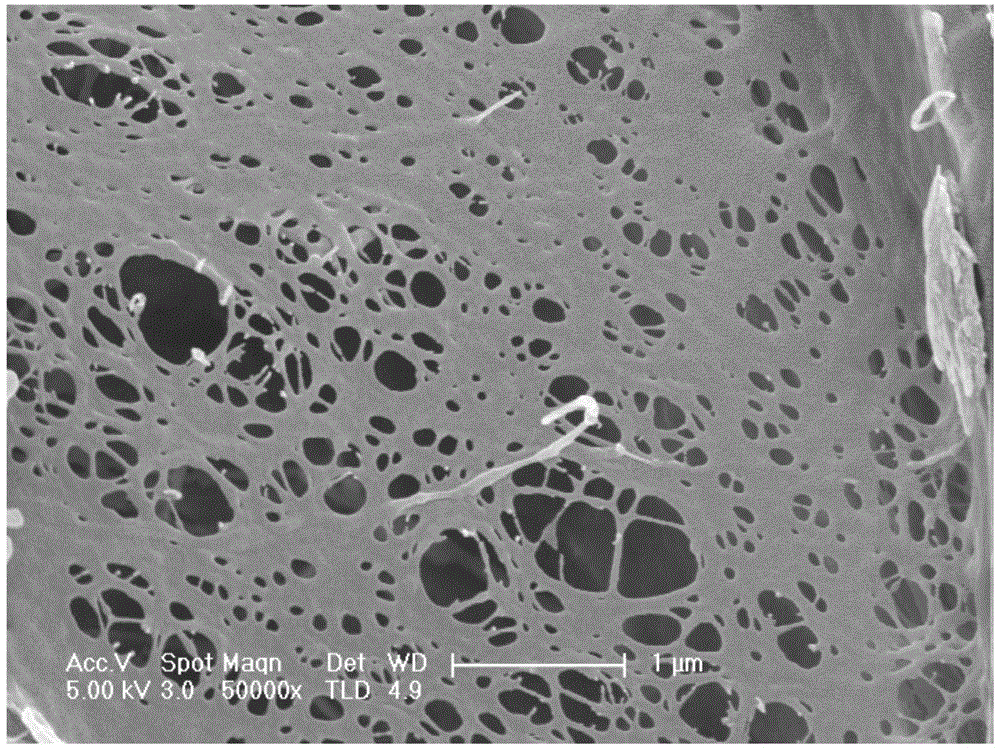

[0031] Such as figure 1 Shown, a kind of polypropylene porous membrane comprises following components: the polypropylene resin of 100 weight parts, the compatibilizer of 5 weight parts, the porogen of 5 weight parts, wherein: the molecular weight distribution value of described polypropylene resin for 14.

[0032] The polypropylene resin is isotactic polypropylene, the compatibilizer is acrylic acid grafted polypropylene, and the porogen is an acrylate-containing silicone polyether copolymer.

[0033] The preparation method that a kind of polypropylene porous film as above adopts comprises the following steps:

[0034] a) After mixing isotactic polypropylene, acrylic acid grafted polypropylene, and acrylate-containing silicone polyether copolymer in proportion, kneading by a screw extruder, and extruding to obtain a polypropylene porous membrane Composite film substrate;

[0035] b) put the composite film substrate obtained in step a) into a sealed high-pressure foaming con...

Embodiment 2

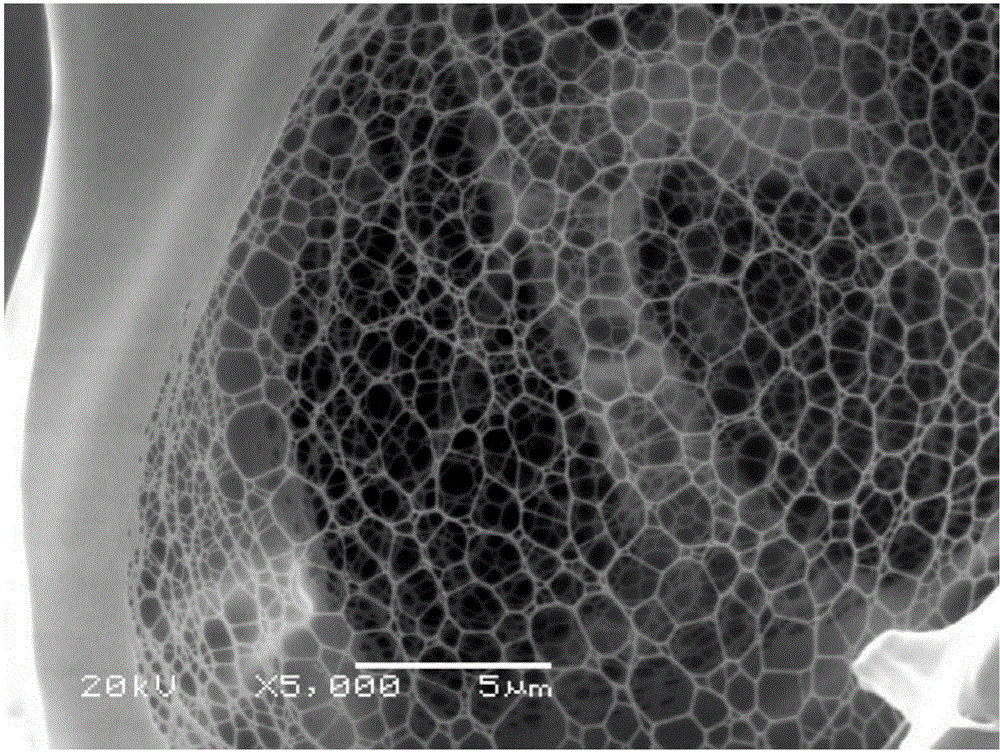

[0037] Such as figure 2 Shown, a kind of polypropylene porous membrane comprises following components: the polypropylene resin of 100 weight parts, the compatibilizer of 11 weight parts, the porogen of 15 weight parts, wherein: the molecular weight distribution value of described polypropylene resin for 25.

[0038] The polypropylene resin is random copolymerized polypropylene, the compatibilizer is glycidyl methacrylate grafted polypropylene, and the porogen is fluorine-containing silicone polyether copolymer.

[0039] The preparation method that a kind of polypropylene porous film as above adopts comprises the following steps:

[0040] a) After mixing random copolymerized polypropylene, glycidyl methacrylate grafted polypropylene, and fluorine-containing silicone polyether copolymer in proportion, kneading by a screw extruder, and extruding to obtain Composite film substrate of polypropylene porous membrane;

[0041] b) the composite film base material obtained in step a...

Embodiment 3

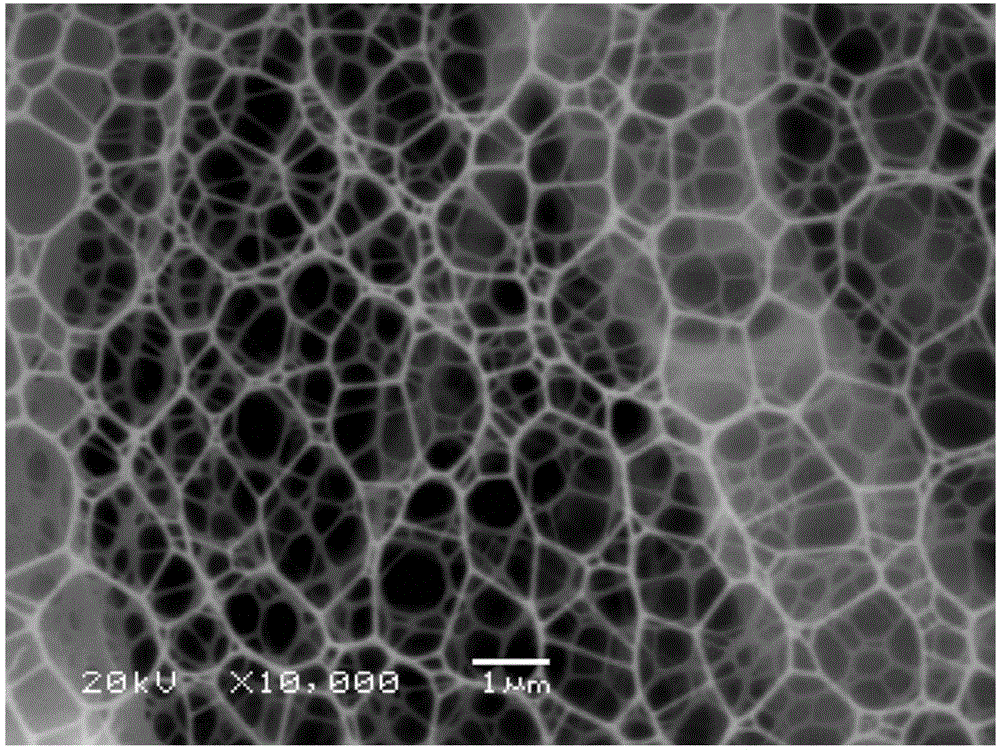

[0043] Such as image 3 Shown, a kind of polypropylene porous membrane comprises following components: the polypropylene resin of 100 weight parts, the compatibilizer of 13 weight parts, the porogen of 21 weight parts, wherein: the molecular weight distribution value of described polypropylene resin for 17.

[0044] The polypropylene resin is isotactic polypropylene, the compatibilizer is maleic anhydride grafted polypropylene, and the porogen is polyether copolymer containing acrylate silicone.

[0045] The preparation method that a kind of polypropylene porous film as above adopts comprises the following steps:

[0046] a) After mixing isotactic polypropylene, maleic anhydride grafted polypropylene, and acrylate-containing silicone polyether copolymer in proportion, kneading by a screw extruder and extruding to obtain Composite film substrates for porous membranes;

[0047] b) the composite film substrate obtained in step a) is put into a sealed high-pressure foaming cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com