Transparent soap

A transparent soap and raw material technology, which is applied in the manufacture of soap solution, alkali soap/ammonium soap composition, soap detergent composition, etc., can solve the problems of low fatty acid content of products, undurable products, and high technical requirements of transparent soap, and achieve The effect of high content of effective active substances, strong product durability, and wide application range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

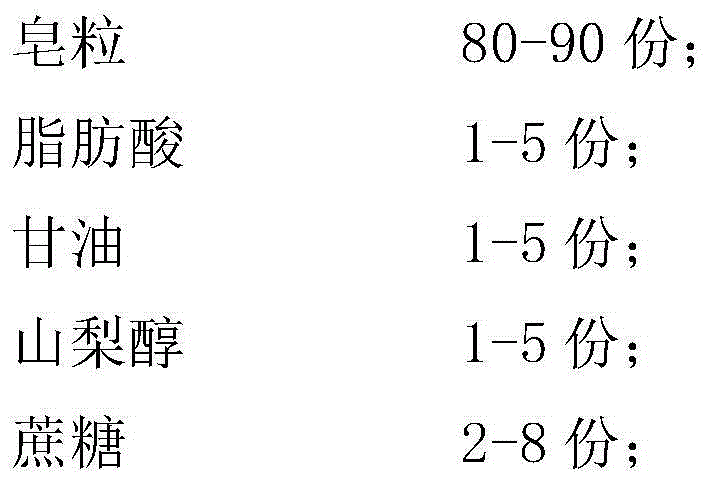

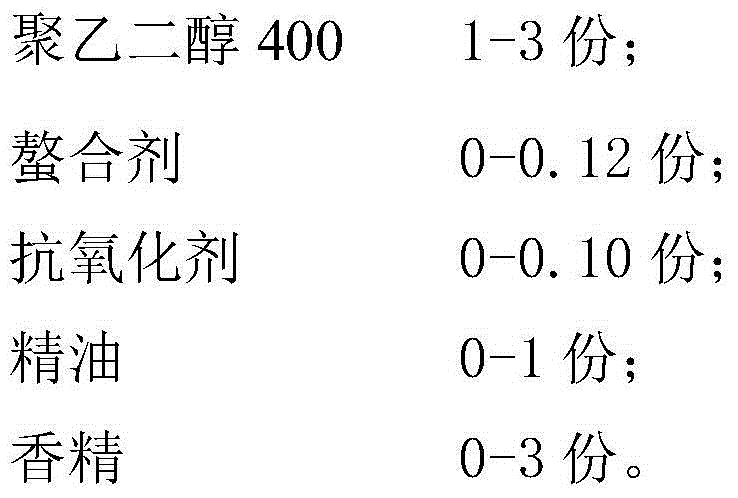

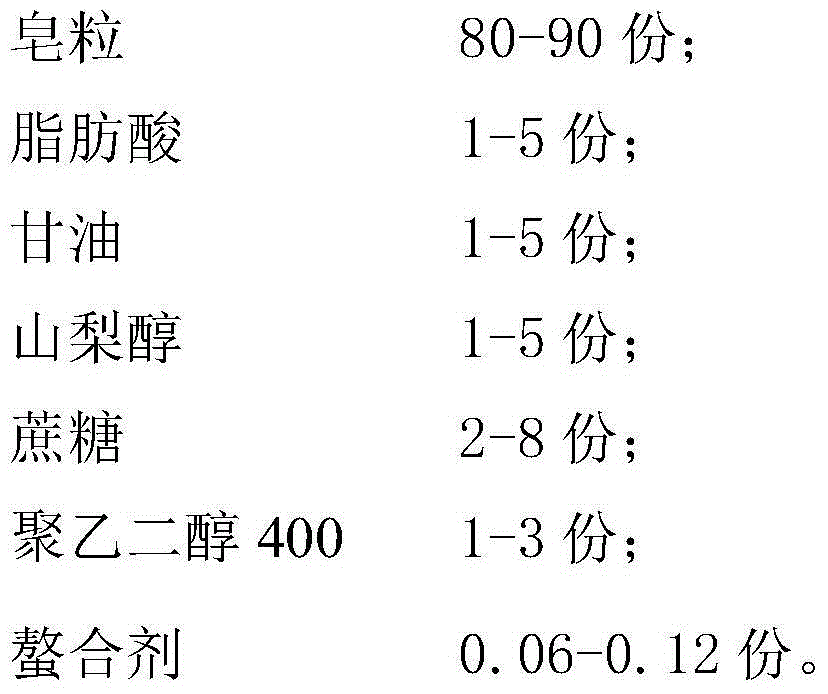

Method used

Image

Examples

Embodiment 1-4

[0031] Each raw material is taken by weighing according to the corresponding embodiment 1-4 data of table 1.

[0032] (a) Add each raw material into a kneader for conventional soap making, knead and stir to mix evenly, stir for 12 minutes, and the stirring temperature is 55° C.;

[0033] (b) Add the kneaded, stirred and evenly mixed material into a mill to grind the soap body, and the thickness of the soap flakes after milling is controlled at 0.4 mm;

[0034] (c) Put the milled soap flakes into a vacuum layering machine for vacuum layering, wherein the outlet temperature of the layering nozzle is controlled at 50°C, and the cooling water temperature of the layering machine is controlled at 3°C;

[0035] (d) The long soap body extruded by the plodder is directly entered into the printer for printing to obtain a shaped soap body, wherein the temperature of the mold during printing is -10°C.

[0036] The transparent toilet soap of the present invention can be obtained.

[0037...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com