Bacterial strain mutagenesis cultivation in membrane bioreactor and adenosine fermentation method

A membrane bioreactor, adenosine deaminase technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of gene number and activity decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

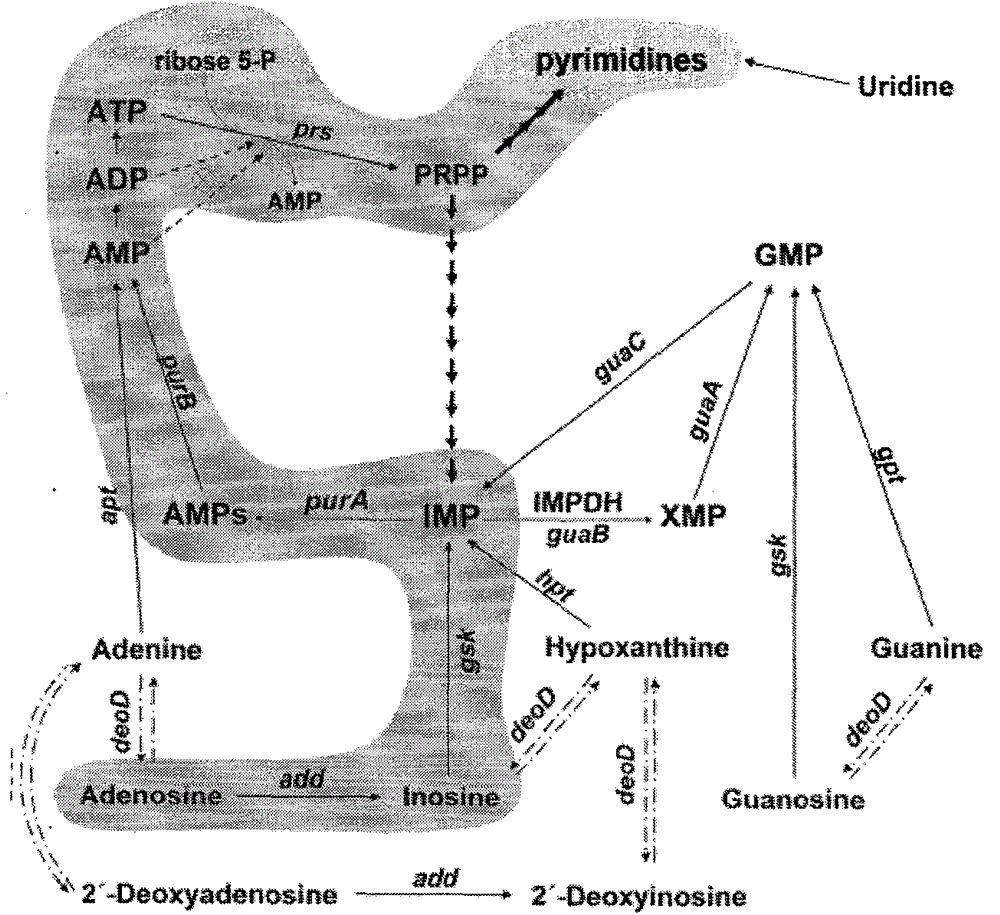

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The strain is added into the solution containing the enzyme inhibitor, and after 3-6 hours of treatment, the membrane experimental device is started for aerobic fermentation. The oxygen flow rate is about 1.6L / min (2L fermentation liquid), and the pH value is adjusted in the range of 6-6.2 with ammonia water during the fermentation process. During the experiment, the ultraviolet absorbance of the membrane permeate was tested, and the fermentation was stopped when the absorbance did not increase.

[0011] 1. Comparison of the experimental rate of hollow fiber ultrafiltration membrane cell cycle fermentation bioreactor fermentation and conventional fermentation

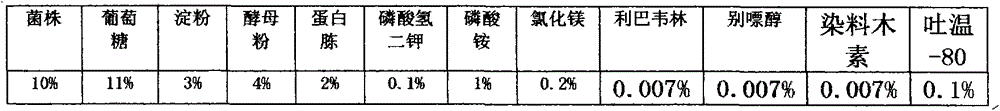

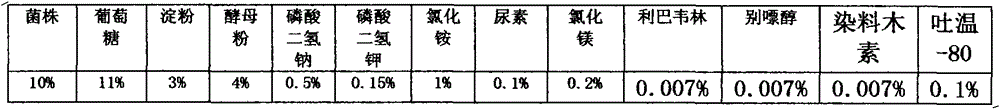

[0012] Under the condition that the fermentation medium composition is shown in Table 1, see Table 2 and Table 3 for the hollow fiber ultrafiltration membrane cell circulation fermentation bio-fermentation bioreactor and conventional fermentation experiments

[0013] Table 1. Fermentation medium composition

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com