High-property optothermal transformation multiple-element alloy nitride film and preparation method thereof

A light-to-heat conversion and multi-element technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as optical performance degradation, binding force degradation, peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

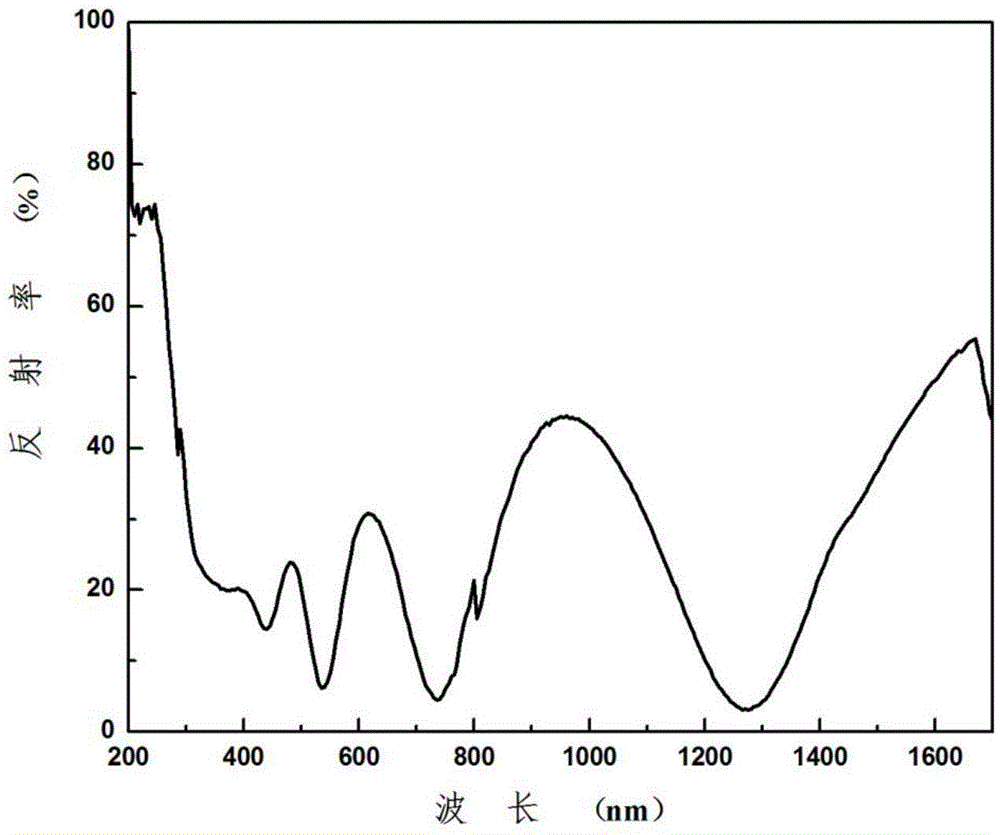

Embodiment 1

[0030] The composition is a NbTiAlSi quaternary alloy target with an equimolar ratio of 1:1:1:1. The vacuum magnetron sputtering coating process is used, and the working gas Ar and the reactive gas N2 are filled, and the uniformity is obtained by changing the working pressure and sputtering time. of different thicknesses of multielement alloy nitride films. Specifically include the following steps:

[0031] Step 1: Put the quartz glass sheet (for the film thickness test) and the polished stainless steel substrate into alcohol and deionized water for ultrasonic cleaning respectively for 15min, and repeat the above process twice;

[0032] Step 2: drying the cleaned substrate and placing it on the sample stage corresponding to the vacuum chamber, and placing the prepared quaternary alloy target on the evaporation source of the vacuum chamber and connecting the DC power source;

[0033] Step 3: Close the magnetron sputtering vacuum chamber, when the vacuum degree is lower than 1....

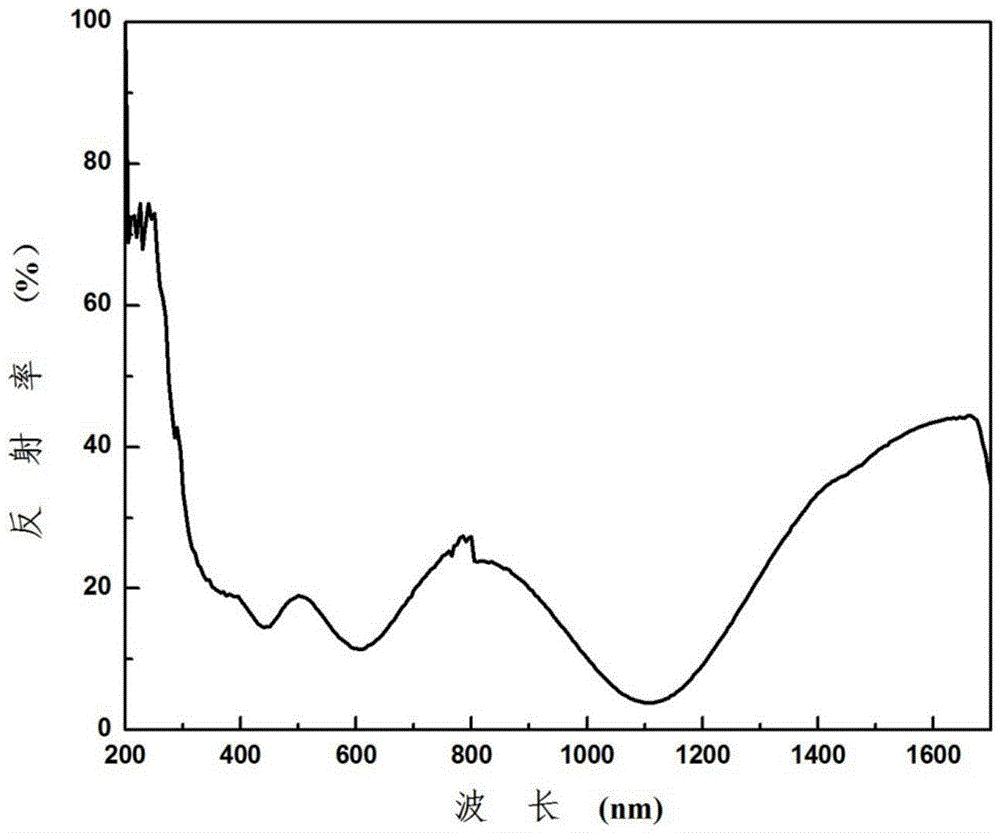

Embodiment 2

[0038] The composition is a NbTiAlSi quaternary alloy target with an equimolar ratio of 1:1:1:1. The vacuum magnetron sputtering coating process is used, and the working gas Ar and reactive gas N2 are filled. Uniform multielement alloy nitride films with different thicknesses were obtained. Specifically include the following steps:

[0039] Step 1: Put the quartz glass sheet (for the film thickness test) and the polished stainless steel substrate into alcohol and deionized water for ultrasonic cleaning respectively for 15min, and repeat the above process twice;

[0040] Step 2: drying the cleaned substrate and placing it on the sample stage corresponding to the vacuum chamber, and placing the prepared quaternary high-entropy alloy target on the evaporation source of the vacuum chamber and connecting the DC power source;

[0041] Step 3: Close the magnetron sputtering vacuum chamber, when the vacuum degree is lower than 1.0×10-3Pa, fill in 20sccm of Ar and 6sccm of N2;

[004...

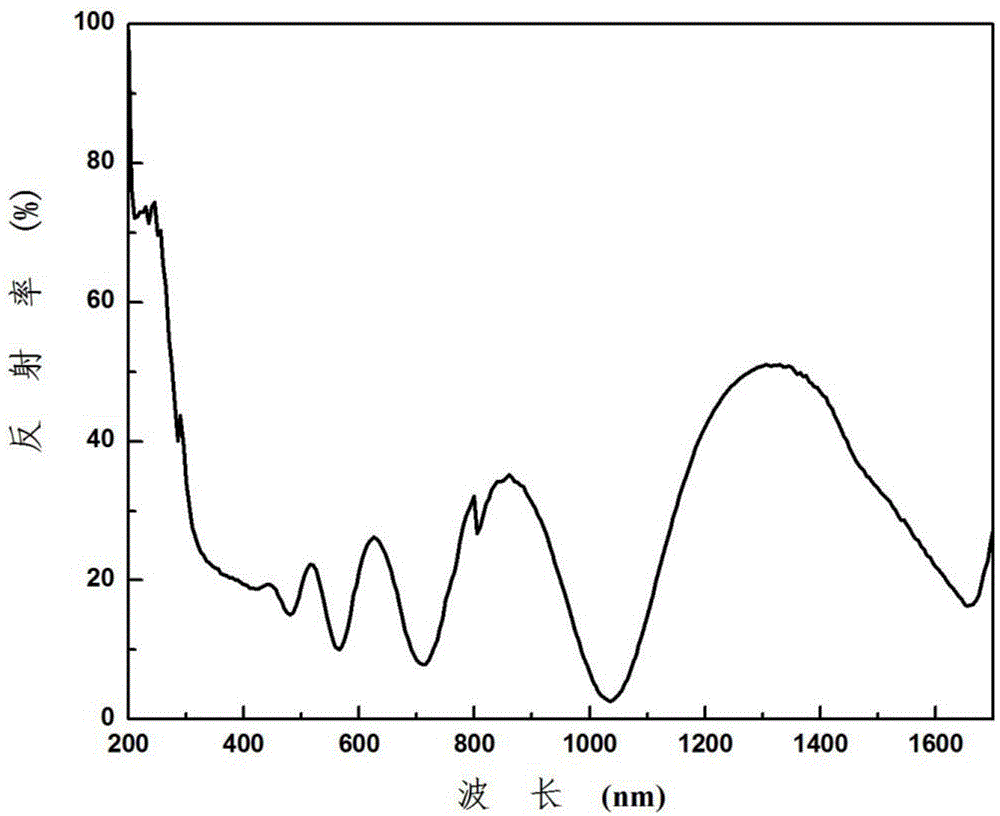

Embodiment 3

[0046]The composition is a NbTiAlSi quaternary high-entropy alloy target with an equimolar ratio of 1:1:1:1. The vacuum magnetron sputtering coating process is used to fill the working gas Ar and reactive gas N2. By changing the working pressure and sputtering time to obtain uniform high-entropy alloy nitride films of different thicknesses. Specifically include the following steps:

[0047] Step 1: Put the quartz glass sheet (for the film thickness test) and the polished stainless steel substrate into alcohol and deionized water for ultrasonic cleaning respectively for 15min, and repeat the above process twice;

[0048] Step 2: drying the cleaned substrate and placing it on the sample stage corresponding to the vacuum chamber, and placing the prepared quaternary alloy target on the evaporation source of the vacuum chamber and connecting the DC power source;

[0049] Step 3: Close the magnetron sputtering vacuum chamber, when the vacuum degree is lower than 1.0×10-3Pa, fill wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com