High-efficiency electrolytic phosphating solution

An electrolytic phosphating solution and high-efficiency technology, applied in the field of electrolytic phosphating solution, can solve the problems of long reaction time, great physical injury to operators, high price, etc., achieve uniform coating, avoid physical injury of operators, and prepare handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

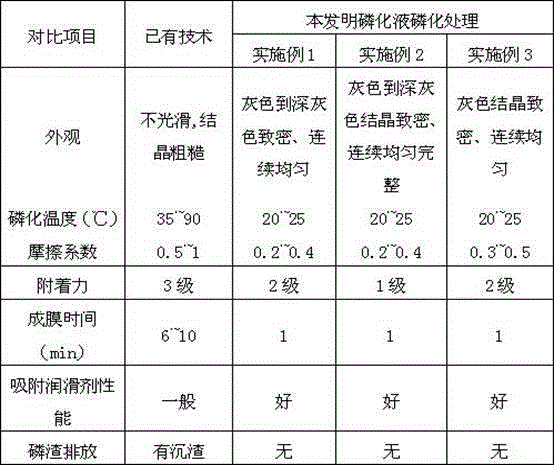

Examples

Embodiment 1

[0016] High-efficiency electrolytic phosphating solution, its raw materials are composed of:

[0017] Phosphoric acid (85%) 120g / l

[0018] Zinc Oxide (99%) 73g / l

[0019] Nitric acid (68%) 70g / l

[0020] Calcium carbonate 200g / l

[0021] Citric acid 20g / l

[0022] Tartaric acid 4g / l

[0024] Nickel nitrate 4g / l

[0025] Fluorosilicate 4g / l

[0027] Oxalic acid 2g / l

[0028] Deionized water balance

[0029] Among them, citric acid, tartaric acid, sodium nitrate, nickel nitrate, fluosilicic acid, copper sulfate, and oxalic acid are additives.

[0030] The above-mentioned high-efficiency electrolytic phosphating solution is prepared through the following steps:

[0031] 1) Into a container, first inject 1 / 5-1 / 4 of the total volume of the electrolytic phosphating solution to be prepared (for example, the total volume of the electrolytic phosphating solution to be prepared is 1 liter, first inject The deionized ...

Embodiment 2

[0035] High-efficiency electrolytic phosphating solution, its raw materials are composed of:

[0036] Phosphoric acid (85%) 130g / l

[0037] Zinc Oxide (99%) 70g / l

[0038] Nitric acid (68%) 75g / l

[0039] Calcium carbonate 190g / l

[0040] Citric acid 18g / l

[0041] Tartaric acid 3g / l

[0042] Sodium nitrate 3g / l

[0043] Nickel nitrate 3g / l

[0044] Fluorosilicate 3g / l

[0045] Copper sulfate 2g / l

[0046] Oxalic acid 2g / l

[0047] Deionized water balance

[0048] Among them, citric acid, tartaric acid, sodium nitrate, nickel nitrate, fluosilicic acid, copper sulfate, and oxalic acid are additives.

[0049] The preparation steps of the above-mentioned high-efficiency electrolytic phosphating solution are the same as in Example 1.

Embodiment 3

[0051] High-efficiency electrolytic phosphating solution, its raw materials are composed of:

[0052] Phosphoric acid (85%) 140g / l

[0053] Zinc Oxide (99%) 68g / l

[0054] Nitric acid (68%) 65g / l

[0055] Calcium carbonate 210g / l

[0056] Citric acid 6g / l

[0057] Copper sulfate 2g / l

[0058] Oxalic acid 2g / l

[0059] Deionized water balance

[0060] Among them, citric acid, copper sulfate, and oxalic acid are additives.

[0061] The preparation steps of the above-mentioned high-efficiency electrolytic phosphating solution are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com