Patents

Literature

54results about How to "Polarization current density is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

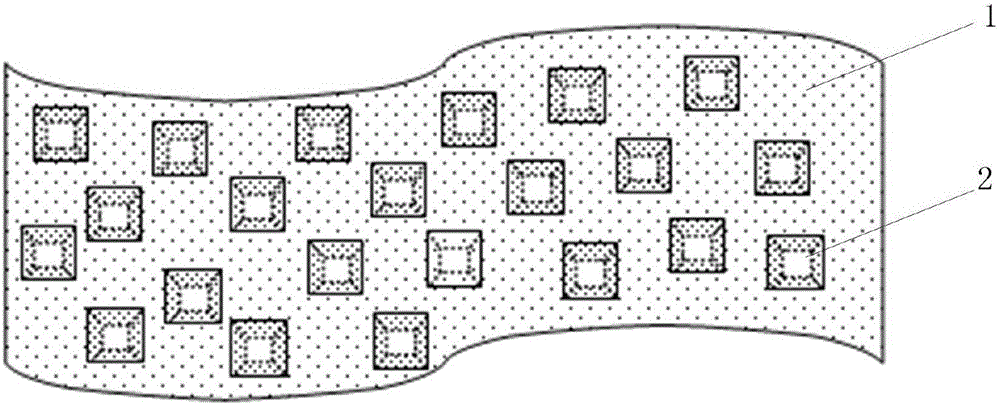

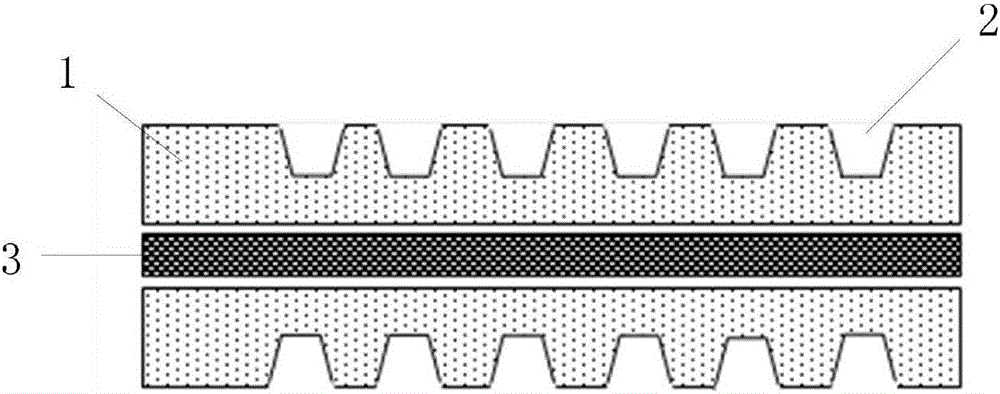

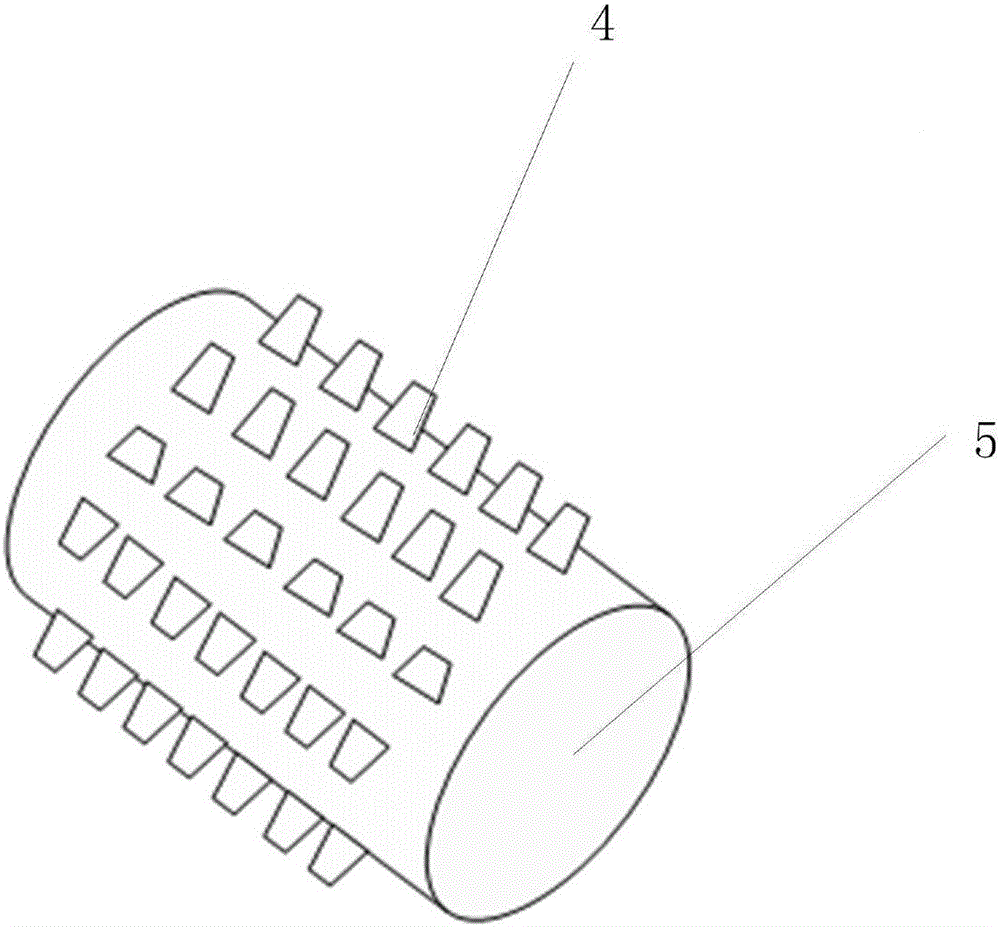

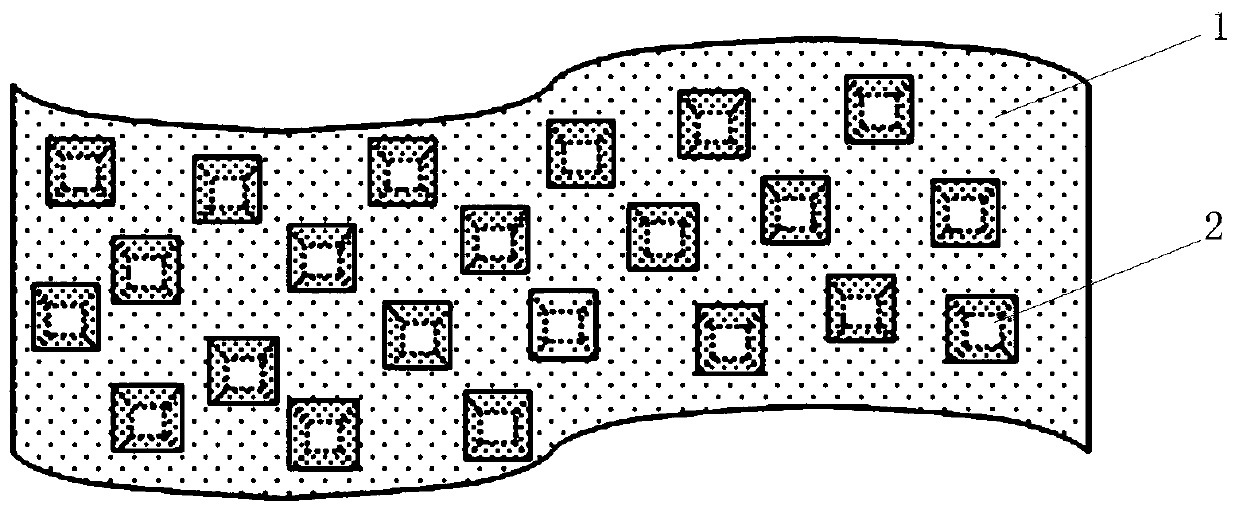

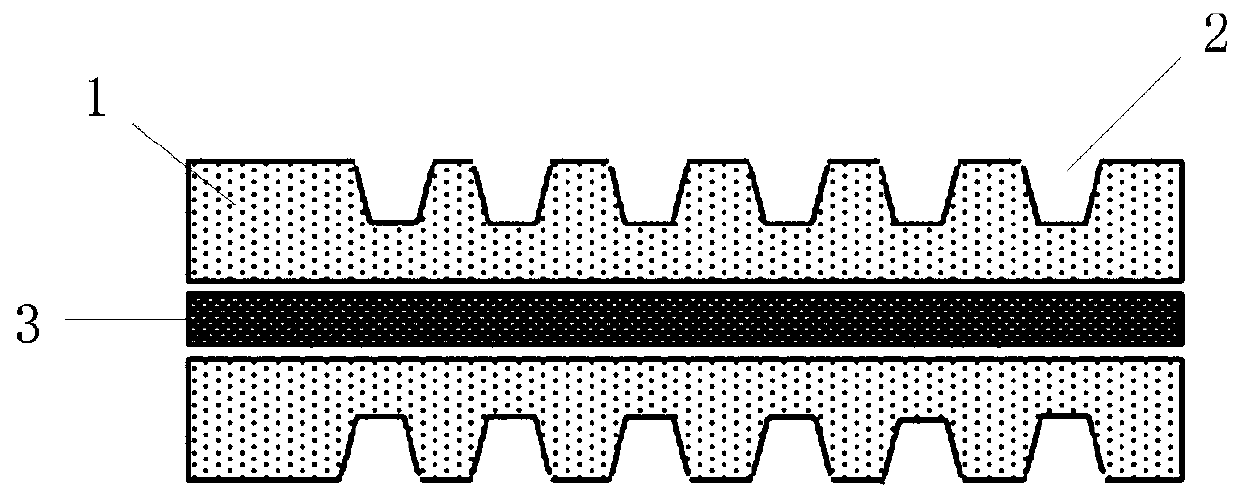

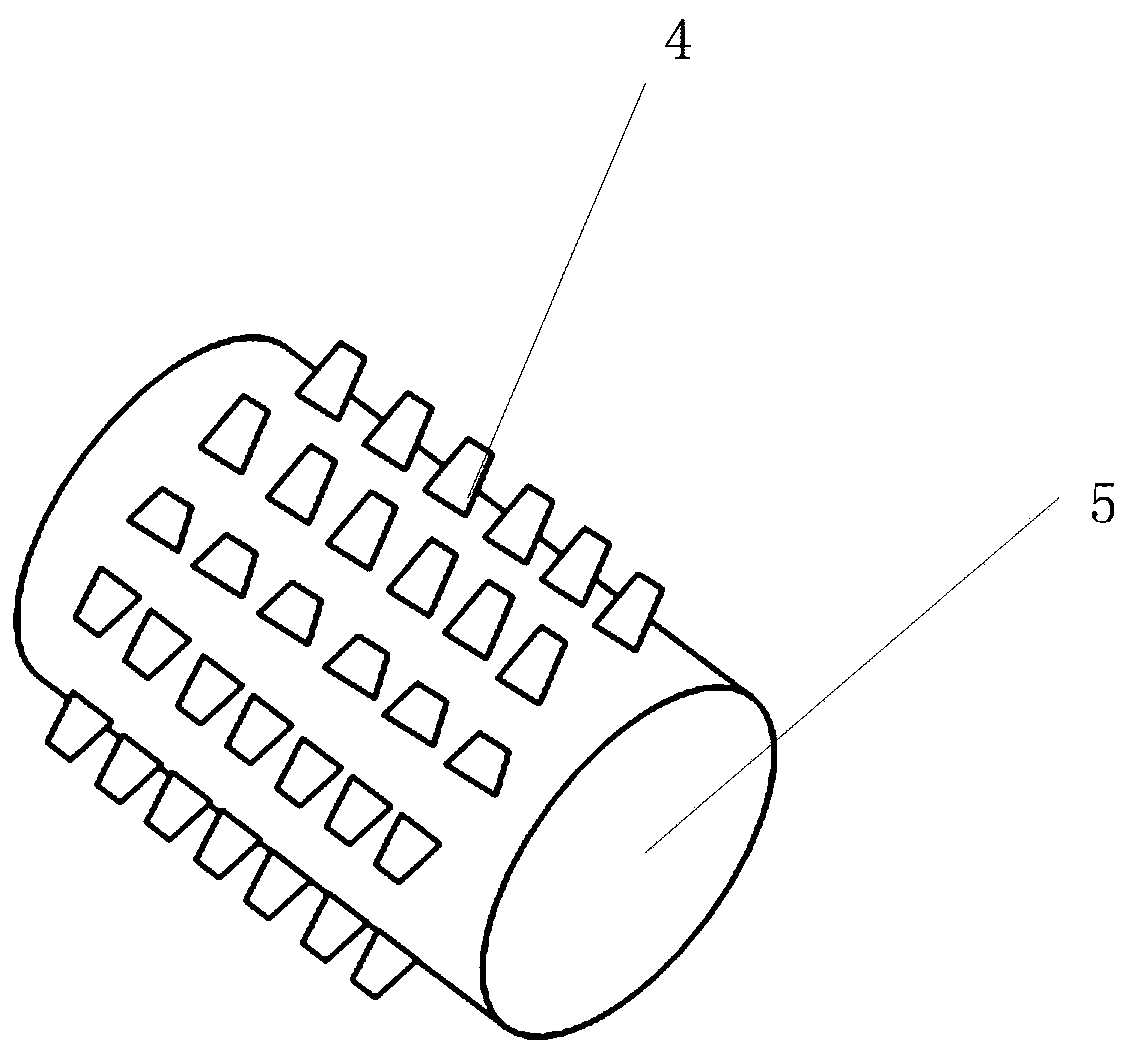

Electrode pole plate of lithium ion battery, pole plate rolling device and lithium ion battery

ActiveCN106531961APromote infiltrationIncrease migration rateElectrode rolling/calenderingSecondary cellsElectrolytic agentCharge discharge

The invention discloses an electrode pole plate of a lithium ion battery. The electrode pole plate comprises a current collector and active substance coating layers, wherein the active substance coating layers are uniformly coated at two sides of the current collector, and grooves are symmetrically and uniformly formed in surfaces of the active substance coating layers at two sides. A thick pole plate with specially-shaped grooves in a surface are prepared, the electrolyte retention quantity in the battery can be remarkably increased, and long-term recycle of the battery is promoted; moreover, the specially-shaped grooves are uniformly formed in the surface of the thick pole plate, electrolyte penetration and diffusion are facilitated, and the rate charge-discharge electrochemical performance of the battery is improved; and meanwhile, the specially-shaped grooves are uniformly formed in the surface of the thick pole plate, thus, the specific area of the pole plate is expanded, the polarization current density of the battery during the charge-discharge process is reduced, a lithium precipitation risk of a large-current charging positive electrode separator is improved, and the application safety of the battery is improved.

Owner:欣旺达惠州动力新能源有限公司

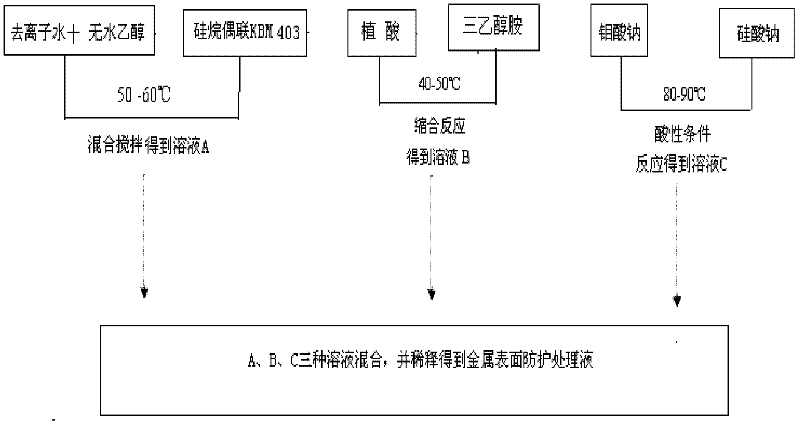

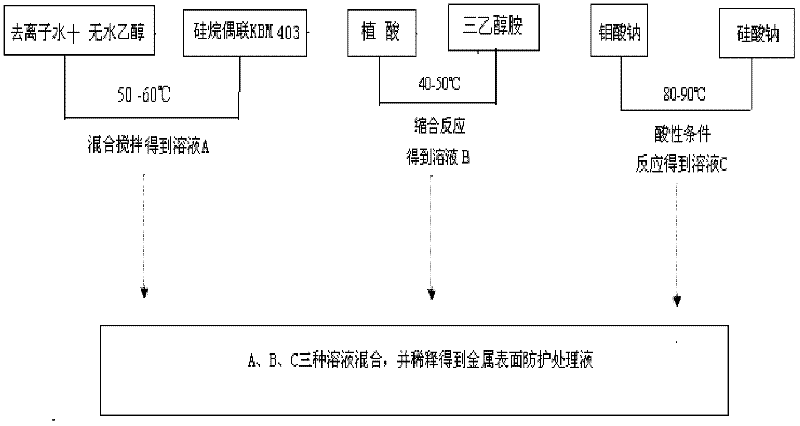

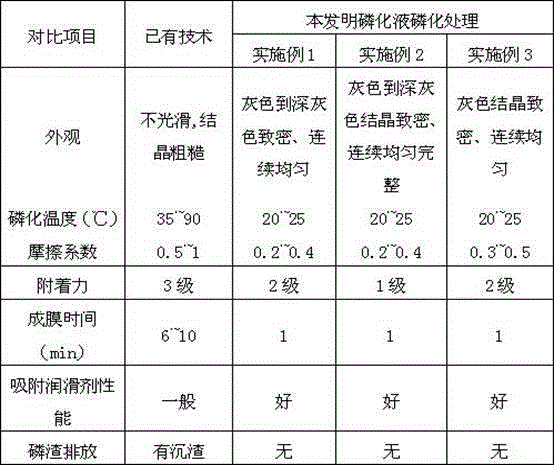

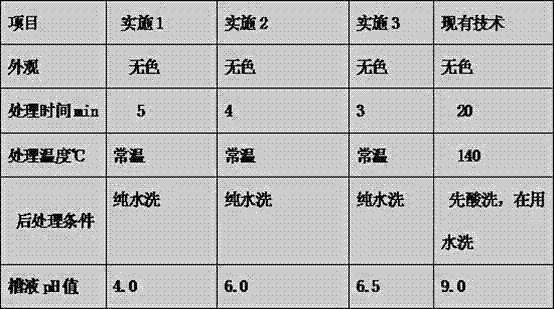

Preparation process of metal surface protective treatment fluid

InactiveCN102534595AStrong adhesionImprove adhesionMetallic material coating processesSodium molybdatePhytic acid

The invention provides a preparation process of metal surface protective treatment fluid, which comprises the following steps: firstly, respectively preparing a main agent solution, and two additive solutions, fully mixing and uniformly stirring the main agent solution and the two additive solutions so as to complete the preparation process of the metal surface protective treatment fluid, wherein 1 liter of the metal surface protective treatment fluid is prepared by the following components by weight: 13-50 g of silane coupling agent KBM403, 1-3 g of phytic acid, 1.5-9 g of triethanolamine, 0.2-0.4 g of sodium molybdate, 3-8 g of sodium silicate, 95-105 g of ethanol, and the balance of water. When the metal surface protective treatment fluid prepared by the method of the invention is used for treating a metal workpiece, a film layer is formed on the metal surface, which has the characteristics of strong adhesion, denseness, uniformity, and low polarized current density; the preparation process of the invention improves the deficiencies of existing metal surface pretreatment process, thus allows better application of metal surface pretreatment, and can substitute phosphatization and blackening technology. Meanwhile, the production and application processes are environment-friendly and cause no pollution.

Owner:蚌埠市钰诚五金工贸有限公司

Surface silanization protection treatment agent for hard aluminum alloy and preparation method thereof

InactiveCN103087572AImprove corrosion resistancePolarization current density is smallAnti-corrosive paintsGramMaleic anhydride

The invention discloses a surface silanization protection treatment agent for hard aluminum alloy. The surface silanization protection treatment agent is prepared from the following ingredients in weight (gram) in every 500g of mixture liquid: 1-2g of monoethanolamine benzoate, 3-5g of guar gum, 3-5g of rosin, 1-2g of trihydroxyethyl isocyanurate, 10-12g of maleic anhydride, 4-6g of diethylene glycol butyl ether, 5-8g of propylene glycol, 3-5g of butane diacid, 8-12g of vinyl triethoxysilane and the balance of deionized water. According to the surface silanization protection treatment agent, rosin serving as a reaction raw material is polymerized with raw materials, such as maleic anhydride and silane, and then, a strong protecting film can be formed on the surface of metal; and the corrosion resistance of metallic matrixes is enhanced.

Owner:重庆全景机械制造有限公司

Metal surface silicane treating agent containing polyethylene glycol and preparing method thereof

InactiveCN103059721AImprove corrosion resistancePolarization current density is smallAnti-corrosive paintsPolyethylene glycolPhytic acid

The invention discloses a metal surface silicane treating agent containing polyethylene glycol and a preparing method thereof. The metal surface silicane treating agent containing the polyethylene glycol is a mixed solution which is prepared from following compositions of silane coupling agent KBM403, film forming resin, the polyethylene glycol, ammonium molybdate, propylene glycol, acetic styrene-acrylic emulsion, phytic acid, polydimethyl siloxane, oxalate, pyrocatechin and ethanol. The metal surface silicane treating agent containing the polyethylene glycol is low in cost by using the silane coupling agent KBM403 as main materials and the ethanol as solvent, and simultaneously the polyethylene glycol and various accessory ingredients are added into raw materials, so that processing time and processing temperature of the treating agent are improved. When a metal workpiece is processed by using the silicane treating agent, a polyacid film layer is formed on the surface of the metal workpiece, and the film layer has the advantages of being strong in adhesive force, without a cavity and a rift, compact and uniform and low in polarization current density, and furthermore the production process is environment-friendly and pollution-free.

Owner:WUHU HENGKUN AUTO PARTS

High-efficiency electrolytic phosphating solution

The invention relates to a high-efficiency electrolytic phosphating solution which is composed of 100-150 g / L phosphoric acid, 71-75 g / L zinc oxide, 60-80 g / L nitric acid, 180-220 g / L calcium carbonate, 8-40 g / L additive and the balance of deionized water. The additive is citric acid or tartaric acid or sodium nitrate or nickel nitrate or copper sulfate or fluosilicic acid, or a mixture of any combination. The preparation method comprises the following steps: injecting the deionized water into a container, adding the phosphoric acid and nitric acid, heating while stirring, slowly adding the zinc oxide while stirring when the temperature reaches 80 DEG C, and stopping heating when the zinc oxide is completely dissolved; continuing stirring for half an hour, adding the calcium carbonate, and continuing stirring for half an hour; and cooling the obtained solution to room temperature, adding the additive, continuing stirring until the additive is completely dissolved, and adding the deionized water to the specified volume, thereby obtaining the electrolytic phosphating solution. The phosphating solution has the characteristic of no toxicity, can be used at normal temperature, and avoids physical damage to the operators and the waste of resources.

Owner:BENGBU YUCHENG NEW MATERIAL TECH

Metal surface silicane treating agent containing tetraisopropyl titanate and preparing method thereof

ActiveCN103060791AImprove corrosion resistancePolarization current density is smallMetallic material coating processesDiethylene glycol monobutyl etherTetraisopropyl titanate

The invention discloses a metal surface silicane treating agent containing tetraisopropyl titanate and a preparing method thereof. The metal surface silicane treating agent containing the tetraisopropyl titanate is prepared form following compositions of, by weight (g) in every 500g of mixed liquor, 1-2g of tetraisopropyl titanate, 1-2g of amine benzoate, 3-5g of rosin, 1-2g of trihydroxyethyl isocyanurate, 10-12g of maleic anhydride, 4-6g of diethylene glycol monobutyl ether, 5-8g of propylene glycol, 2-3g of formic acid, 10-12g of N-(beta-aminoethyl)-gamma- aminopropyl trimethyl (triethyl) oxygroup silicane and the balance deionized water. The metal surface silicane treating agent containing the tetraisopropyl titanate and the preparing method use the rosin as reacting raw materials to polymerize with raw materials of the maleic anhydride, the silicane and the like, and accordingly strong protective film can be formed on the surface of metal, and decay resistance of a metal matrix is strengthened.

Owner:上海蓝烷新材料科技有限公司

Metallic workpiece pretreatment silane surface treatment agent and preparation method thereof

ActiveCN103031550AImprove corrosion resistancePolarization current density is smallMetallic material coating processesOXALIC ACID DIHYDRATESodium phosphates

The invention discloses a metallic workpiece pretreatment silane surface treatment agent which is a mixed liquor prepared by the following components based on the weight (gram) in each liter of the mixed liquor: 15-20 parts of A-187 silane coupling agent, 3-4 parts of film-forming material, 7-8 parts of KH-570 silane coupling agent, 3-4 parts of acrylic resin emulsion, 3-5 parts of sodium molybdate, 0.05-0.1 parts of lanthanum nitrate, 0.8-1.2 parts of ethylene glycol, 13-15 parts of propylene glycol, 0.1-0.3 parts of oxalic acid, 2-4 parts of phytic acid, 90-95 parts of methyl alcohol, and the balance of deionized water. The silane coupling agent KH572, ammonium molybdate, propylene glycol, borax, sodium tripolyphosphate and the like are taken as the film-forming materials and reaction raw materials to perform polymerization, form the stronger protective film for the metallic workpiece pretreatment, and strengthen the corrosion resistance of the metallic matrix.

Owner:安徽众鑫科技股份有限公司

Protective treating agent for silanizing surface of anti-corrosion stainless steel plate surface and preparation method thereof

ActiveCN103059625AImprove corrosion resistancePolarization current density is smallAnti-corrosive paintsDiethylene glycol monobutyl etherPolyethylene glycol

The invention discloses a protective treating agent for silanizing the surface of an anti-corrosion stainless steel plate surface. The protective treating agent is prepared from the following components by weight (g) in each 500 grams of mixed solution 1 to 2g of ammonium chloride, 1 to 2g of diethylamine, 2 to 3g of tetraisopropyl titanate, 3 to 5g of rosin, 1 to 2g of 1,3,5-tris(2-hydroxyethyl) cyanuric acid, 10 to 12g of maleic anhydride, 4 to 6g of diethylene glycol monobutyl ether, 10 to 12g of polyethylene glycol, 3 to 5g of oxalic acid, 1 to 2g of urea, 10 to 12g of aminopropyl triethoxy silane, and the balance of deionized water. According to the protective treating agent, the rosin is used as a reaction raw material and is polymerized with raw materials such as the maleic anhydride and silane, and a stronger protective film can be formed on the metal surfaces; and the corrosion resistance of metal matrixes is enhanced.

Owner:FUJIAN MEIKE STAINLESS STEEL PROD

Metal surface silicane treating agent containing diethanol amine and preparing method thereof

ActiveCN103060787AImprove corrosion resistanceExtended service lifeMetallic material coating processesDiethylene glycol monobutyl etherZno nanoparticles

The invention discloses a metal surface silicane treating agent containing diethanol amine. The metal surface silicane treating agent containing the diethanol amine is characterized by being a mixed solution which is prepared from following compositions of, by weight part ratio in every liter of the mixed solution, 28-35 parts of 1,2-bis (triethoxy silicon) ethane, 32-40 parts of gamma-aminopropyl triethoxy silicane, 100-160 parts of aqueous nanometer zinc oxide material, 2-3 parts of allyl alcohol, 1-2 parts of ethylene glycol, 2-3 parts of sodium tripolyphosphate, 2-4 parts of propylene glycol, 2-3 parts of zirconium tetrafluoride, 2-3 parts of diethanol amine, 2-3 parts of ammonium chloride, 1-2 parts of diethylene glycol monobutyl ether, 1-2 parts of trimethylolpropane, 0.3-0.5 part of sodium dodecyl benzene sulfonate, and the balance water. The metal surface silicane treating agent containing the diethanol amine has the advantages that, a silicane coating formed on the surface of metal after the metal is processed by using the surface silicane treating agent has good decay resistance, service life of the metal is prolonged, and a compact and firm coating is formed on the surface of the metal by combining the 1,2-bis (triethoxy silicon) ethane and the gamma-aminopropyl triethoxy silicane for use.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Lithium-ion battery electrode pole piece, pole piece rolling device and lithium-ion battery

ActiveCN106531961BPromote infiltrationIncrease migration rateElectrode rolling/calenderingSecondary cellsElectrical batteryCharge discharge

Owner:SUNWODA HUIZHOU POWER NEW ENERGY CO LTD

Silane finishing agent at surface of galvanized steel sheet and preparation method thereof

InactiveCN103088328AImprove corrosion resistancePolarization current density is smallMetallic material coating processesBenzoic acidSodium bicarbonate

The invention discloses a silane finishing agent at the surface of a galvanized steel sheet and a preparation method thereof. Mixed solution is prepared from the following components of a silane coupling agent KH550, film-forming resin, benzoic acid monoethanolamine, propylene glycol, triethanolamine, carboxyl methyl cellulose, polyvinyl alcohol, oxalic acid, polydimethylsiloxane, hydroquinone sodium bicarbonate and ethanol. The silane coupling agent KH550 is adopted as a primary material; and the ethanol is taken as a solvent, so that the silane finishing agent is low in cost; the benzoic acid monoethanolamine and different auxiliary agents are added to the material at the same time; and the processing time and the processing temperature of the finishing agent are improved. A work-piece is processed by the silane finishing agent disclosed by the invention; a polyacid film is formed at the surface; and the film has the characteristics of being strong in adhesive force, free of a cavity, compact and even in chasm, small in polarization current density, environment-friendly in the production process and free of pollution.

Owner:珠海海特电子科技有限公司

Metal surface silane treating agent and preparation method thereof

ActiveCN103045086AImprove corrosion resistanceExtended service lifeAnti-corrosive paintsSilanesPhosphate

The invention discloses metal surface silane treating agent. The treating agent is characterized by preparing mixed liquid by the following components, and the weight parts (g) of all components in each liter of mixed liquid are as follows: 35 to 45 parts of 3-glycidyl ether oxygroup propyl trimethoxy silane, 35 to 45 parts of vinyl tri(beta-methoxyl ethyoxyl)silane, 100 to 180 parts of aqueous nano-zinc oxide materials, 4 to 5 parts of 2-methyl-1, 3-propylene glycol, 2 to 4 parts of polyethylene glycol, 2 to 2.5 parts of zirconium fluoride, 2 to 3 parts of dimethyl sulfoxide, 1 to 2 parts of urea, 0.3 to 0.6 part of benzotriazole, 0.3 to 0.5 part of monoammonium phosphate and the rest amount of water. The treating agent has the advantages that after the metal is treated by the surface silane treating agent, a silane coating layer formed on the metal surface has excellent corrosion resistance, and the service life of the metal is prolonged; and as propyl trimethoxy silane is combined with aminopropyl triethoxy silane for use, the compact and firm coating layer can be formed on the metal surface.

Owner:北京泽凯恩派航空材料有限公司

Surface silanization protection treatment agent for stainless steel plates and preparation method thereof

ActiveCN103087569AImprove corrosion resistancePolarization current density is smallAnti-corrosive paintsGramMaleic anhydride

The invention discloses a surface silanization protection treatment agent for stainless steel plates. The surface silanization protection treatment agent is prepared from the following ingredients in weight (gram) in every 500g of mixture liquid: 2-3g of butane diacid, 1-2g of ammonium molybdate, 5-8g of gelatin, 2-3g of lanthanum nitrate, 3-5g of rosin, 1-2g of trihydroxyethyl isocyanurate, 10-12g of maleic anhydride, 4-6g of diethylene glycol butyl ether, 5-8g of propylene glycol, 2-3g of acetic acid, 1-2g of urea, 10-12g of aminopropyl triethoxysilane and the balance of deionized water. According to the surface silanization protection treatment agent, rosin serving as a reaction raw material is polymerized with raw materials, such as maleic anhydride and silane, and then, strong protecting films can be formed on the surface of metal; and the corrosion resistance of metallic matrixes is enhanced.

Owner:佛山市泰和骏业工贸有限公司

Method for improving surface oxidation resistance of aluminum alloy

ActiveCN105908130AImprove antioxidant capacityNo pollution in the processVacuum evaporation coatingSputtering coatingIndiumPower flow

The invention provides a method for improving surface oxidation resistance of an aluminum alloy, and belongs to the technical field of casting of aluminum alloys. The method comprises the steps of: surface treatment, injection of yttrium, nickel and indium ions, high-temperature curing, spraying of a surface treatment agent and medium-temperature curing. Compared with the prior art, the method selects yttrium, nickel and indium elements as injecting elements, so that the surface oxidation resistance of a magnesium alloy is effectively improved; meanwhile, the surface treatment agent is sprayed to the surface of the aluminum alloy, so that a film formed on the surface is thick and environment-friendly; the film layer is compact and uniform; the density of polarization current is lower; and the film is excellent in corrosion resistance, high in oxidation resistance and lasting in protectiveness. The method is simple in process, wide in application range, capable of modifying the surfaces of the aluminum alloys with various types and free of the environmental pollution problem.

Owner:贵州航天风华精密设备有限公司

Silane treating agent and preparation method thereof

InactiveCN107326354AEasy to makeImprove performanceMetallic material coating processesMolybdateSilanes

The invention discloses a silane treating agent and a preparation method thereof. The silane treating agent comprises, by weight, 2-5 parts of a silane coupling agent, 2-5 parts of phytic acid, 8-14 parts of nitrate, 4-7 parts of molybdate and 70-100 parts of water. The silane treating agent prepared through the method has the beneficial effects of being stable in performance and free of poison and pollution. After the silane treating agent prepared through the method is utilized for treating a metal workpiece, a film layer formed on the metal surface has the beneficial effects of being excellent in adhesive force, compact, uniform and low in polarization current density. The defects of existing metal surface pretreatment are overcome, and therefore the silane treating agent can be applied to metal surface pretreatment better.

Owner:浙江裕辉新材料科技有限公司

Surface silanization protection treatment agent for corrosion inhibiting and resisting metal and preparation method thereof

ActiveCN103087567AImprove corrosion resistancePolarization current density is smallAnti-corrosive paintsBenzoic acidSilanes

The invention discloses a surface silanization protection treatment agent for corrosion inhibiting and resisting metal. The surface silanization protection treatment agent is prepared from the following ingredients in weight (gram) in every 500g of mixture liquid: 1-2g of benzoic acid amide, 1-2g of triethanolamine, 3-5g of methyl cellulose, 8-10g of rosin, 0.5-1.2g of trihydroxyethyl isocyanurate, 10-12g of maleic anhydride, 4-6g of diethylene glycol butyl ether, 5-8g of isopropanol, 0.5-1g of ammonium dihydrogen phosphate, 1-2g of urea, 5-8g of N-2-(aminoethyl)-3-aminopropyl trimethoxysilane and the balance of deionized water. According to the surface silanization protection treatment agent, rosin serving as a reaction raw material is polymerized with raw materials, such as maleic anhydride and silane, and then, a strong protecting film can be formed on the surface of metal; and the corrosion resistance of metallic matrixes is enhanced.

Owner:JIANGSU LIANGYOU STEEL WIRE CO LTD

Metal material silane surface treating agent and preparation method thereof

InactiveCN103088325AImprove corrosion resistancePolarization current density is smallMetallic material coating processesSodium acid carbonateKetone

The invention discloses a metal material silane surface treating agent and a preparation method thereof. The silane surface treating agent is mixed liquid formed by mixing the following components: methyl triethoxysilane, film-forming resin, chitosan, ammonium molybdate, zinc dialkyl dithiophosphate, phytic acid, 2-n-octyl-4-isothiazolin-3-ketone, sodium dodecyl benzene sulfonate, polydimethylsiloxane, catechol, sodium carbonate and ethanol. The silane surface treating agent is prepared by using the methyl triethoxysilane as a main material and ethanol as a solvent; the materials are low in cost; and meanwhile, chitosan and a plurality of different auxiliaries are added into the raw materials, so that the treatment time and the treatment temperature of the treating agent are improved. A metal workpiece is treated by virtue of a silanization treating agent, a multi-acid film layer is formed on the surfaces of the metal workpiece, and the film layer has the characteristics of high adhesion, compactness, uniformity and low polarization current density and no cavity and rifts; and the production process is environment-friendly without pollution.

Owner:枣阳华晨亿龙新材料有限公司

Metal surface silane treating agent containing ammonium metavanadate and preparation method thereof

ActiveCN103031548AExtended service lifeImprove corrosion resistanceMetallic material coating processesDispersion stabilityEnvironmental resistance

The invention discloses a metal surface silane treating agent containing ammonium metavanadate. The metal surface silane treating agent is characterized by being a mixture solution prepared from the following ingredients in parts by weight (gram) in each liter of the mixture: 22-32 parts of 3-(isobutene acyl oxygen) propyl trimethoxy silane, 27-40 parts of N-phenyl-3-amino propyl trimethoxy silane, 100-190 parts of aqueous nano-zinc oxide, 3-5 parts of ethylene diamine tetramethylene risedremate sodium, 3-4 parts of allyl alcohol, 3-4 parts of propylene glycol, 2-3 parts of zirconium fluoride, 2-3 parts of monohydrate ammonia, 1-2 parts of diethanol amine, 1-2 parts of dimethyl sulfoxide, 0.8-1 parts of ammonium metavanadate, 0.7-0.9 parts of bibutyl cellosolve and the balance of water. The aqueous nano-zinc oxide prepared by using the process provided by the invention has high dispersion stability and efficient adhesiveness, and is uniformly distributed on the surface of a metal, so that the metal has high compactness and anti-ion permeability; and due to the added assistant such as the ethylene diamine tetramethylene risedremate sodium and the like, the compactness of a silane absorbing film is increased, the filming quality is improved, the film layer has the characteristics of being strong in adhesion capability, free of cavity and rift, compact and uniform and small in polarization current density, and the production process is environmental-friendly and pollution-free.

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Silanization processing agent for metal piece individually protection

InactiveCN102533104AStrong adhesionPolarization current density is smallAnti-corrosive paintsPre treatmentEthylenediaminetetraacetic acid

The invention provides a silanization processing agent for metal piece individually protection, which is a mixed solution prepared by the following components, and in each liter of the mixed solution, the weight parts of the components are: 30-60 g of 1,2-diethoxylsilyl ethane, 2-5 g of sodium molybdate, 0.5-1.5 g of alpha-sulfo fatty acid methyl ester sodium, 0.1-0.4 g of ethylenediaminetetraacetic acid disodium salt, 4-7 g of isopropanol, and the balance of ethanol solution. The processing agent of the invention is stable in performance, simple in preparation, nontoxic, and free of pollution. When a metal piece is processed by the processing agent of the invention, a film layer formed on the metal surface has the characteristics of strong adhesion, compactness, uniformity, and small polarization current density, which improves the deficiencies of existing metal surface pretreatment, allows better application of metal surface pretreatment, and substitutes phosphatization and blackening technology.

Owner:蚌埠市钰诚五金工贸有限公司

Surface silanization protection treatment agent for corrosion-resistant galvanized steel plates and preparation method thereof

ActiveCN103087566AImprove corrosion resistancePolarization current density is smallAnti-corrosive paintsBenzoic acidSilanes

The invention discloses a surface silanization protection treatment agent for corrosion-resistant galvanized steel plates. The surface silanization protection treatment agent is prepared from the following ingredients by weight (gram) in every 500g of mixture liquid: 1-2g of ammonium carbonate, 2-3g of hexamethylene tetramine, 1-2g of zirconium fluoride, 3-5g of rosin, 1-2g of trihydroxyethyl isocyanurate, 6-9g of maleic anhydride, 4-6g of diethylene glycol butyl ether, 5-8g of isopropanol, 1-2g of urea, 4-6g of benzoic acid, 15-20g of N-2-(aminoethyl)-3-aminopropyl trimethoxysilane and the balance of deionized water. According to the surface silanization protection treatment agent, rosin serving as a reaction raw material and is polymerized with raw materials, such as maleic anhydride and silane, and then, a strong protecting film can be formed on the surface of metal; and the corrosion resistance of metallic matrixes is enhanced.

Owner:南京翰威新材料有限公司

Rosin modified film-formative metal surface silanization protective treating agent and preparation method thereof

InactiveCN103059626AImprove corrosion resistancePolarization current density is smallAnti-corrosive paintsSuccinic acidCis-Butenedioic Acid

The invention discloses a rosin modified film-formative metal surface silanization protective treating agent. In each 500 g of a mixed solution, the rosin modified film-formative metal surface silanization protective treating agent is composed of the following components: 1-2 g of sodium molybdate, 1-2 g of diethylamine, 5-8 g of hydroxyethyl cellulose, 10-15 g of rosin, 1-2 g of tris(2-hydroxyethyl) isocyanurate, 10-12 g of maleic anhydride, 4-6 g of diethylene glycol butyl ether, 5-8 g of propylene glycol, 2-3 g of succinic acid, 12-15 g of phenyltriethoxysilane and the balance of de-ionized water. As the rosin is adopted as a reaction raw material to polymerize with the raw materials such as the maleic anhydride and silicane, a relatively strong protective film can be formed on the metal surface; and corrosion resistance of a metal base body is enhanced.

Owner:WUHU HENGKUN AUTO PARTS

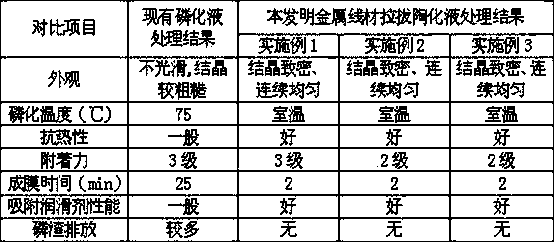

Metal wire drawing vitrifying liquid and preparation method thereof

InactiveCN104264143ASimple processSolve pollutionMetallic material coating processesPotassiumPhytic acid

The invention relates to metal wire drawing vitrifying liquid which comprises the following raw materials by weight: 20-50 g / L of sodium fluozirconate or potassium fluozirconate, 30-40 g / L of sodium fluotitanate or potassium fluotitanate, a silane coupling agent with volume content of 2%-5%, 1-3 ml / L of phytic acid, 1.5-9 ml / L of triethanolamine, 0.2-0.4 g / L of sodium molybdate, 3-8 g / L of sodium silicate, 5-10 g / L of sodium tartrate, 5-10g / L of calcium nitrate, 3-5 g / L of polyoxyethylene ether substances, ethanol with the volume content of 6%-10% and the balance of water. The invention also provides a preparation method of the metal wire drawing vitrifying liquid. The preparation method comprises the processes of raw material mixing, reaction and the like. The metal wire drawing vitrifying liquid disclosed by the invention has the advantages of less energy consumption, low possibility in sediment appearance, economy and environmental friendliness, and a vitrified conversion film formed on the surface of a metal wire is good in adhesive power, dense and uniform in film layer and favorable to metal finish machining and can fundamentally overcome the defects of the existing drawing surface pretreatment of the metal wire, so that the drawing surface pretreatment of the metal wire can be preferably applied, and a phosphatizing drawing treatment technology is substituted.

Owner:BENGBU YUCHENG NEW MATERIAL TECH

A kind of anti-corrosion and anti-corrosion cold-rolled steel plate surface silanization protective treatment agent and preparation method thereof

ActiveCN103059624BImprove corrosion resistancePolarization current density is smallAnti-corrosive paintsBenzoic acidDiethylene glycol monobutyl ether

The invention discloses a corrosion inhibition and corrosion prevention cold rolling steel sheet surface silanization protection treating agent. The corrosion inhibition and corrosion prevention cold rolling steel sheet surface silanization protection treating agent is prepared from compositions of, by weight (g) in every 500g of mixed liquor, 1-2g of ammonium bicarbonate, 1-2g of benzoic acid mono ethanol amine, 0.3-0.5g of lauryl sodium sulfate, 5-8g of isobutyl alcohol, 3-5g of rosin, 1.2-1.5g of 1,3,5-tris(2-hydroxyethyl)cyanuric acid, 10-12g of maleic anhydride, 4-6g of diethylene glycol monobutyl ether, 5-8g of propylene glycol, 3-5g of phytic acid, 1-2 g of anilino-methyl-triethoxysilane, and the balance deionized water. The corrosion inhibition and corrosion prevention cold rolling steel sheet surface silanization protection treating agent uses the rosin as reaction raw materials, polymerizes the rosin with raw materials of the maleic anhydride, silane and the like, can form strong protective film on the surface of metal, and strengthens corrosion resistance of a metallic matrix.

Owner:广东粤华不锈钢型材股份有限公司

A kind of metal surface silane treatment agent and preparation method thereof

ActiveCN103045086BImprove corrosion resistanceExtended service lifeAnti-corrosive paintsPhosphatePolyethylene glycol

The invention discloses metal surface silane treating agent. The treating agent is characterized by preparing mixed liquid by the following components, and the weight parts (g) of all components in each liter of mixed liquid are as follows: 35 to 45 parts of 3-glycidyl ether oxygroup propyl trimethoxy silane, 35 to 45 parts of vinyl tri(beta-methoxyl ethyoxyl)silane, 100 to 180 parts of aqueous nano-zinc oxide materials, 4 to 5 parts of 2-methyl-1, 3-propylene glycol, 2 to 4 parts of polyethylene glycol, 2 to 2.5 parts of zirconium fluoride, 2 to 3 parts of dimethyl sulfoxide, 1 to 2 parts of urea, 0.3 to 0.6 part of benzotriazole, 0.3 to 0.5 part of monoammonium phosphate and the rest amount of water. The treating agent has the advantages that after the metal is treated by the surface silane treating agent, a silane coating layer formed on the metal surface has excellent corrosion resistance, and the service life of the metal is prolonged; and as propyl trimethoxy silane is combined with aminopropyl triethoxy silane for use, the compact and firm coating layer can be formed on the metal surface.

Owner:北京泽凯恩派航空材料有限公司

A metal surface silane treatment agent containing diethyltoluenediamine and its preparation method

InactiveCN103031549BImprove corrosion resistanceExtended service lifeMetallic material coating processesDispersion stabilitySilanes

The invention discloses a metal surface silane treating agent containing plant ash. The metal surface silane treating agent is characterized by being a mixture solution prepared from the following ingredients in parts by weight (gram) in each liter of the mixture: 32-40 parts of vinyl triethoxysilane, 33-48 parts of aminopropyl triethoxy silane, 120-170 parts of aqueous nano-zinc oxide, 2-3 parts of 1,4-cyclohexanedimethanol, 1-2 parts of ethylene glycol butyl ether, 2-3 parts of sodium tripolyphosphate, 2-4 parts of propylene glycol, 2-3 parts of zirconium tetrafluoride, 2-3 parts of ammonium molybdate, 2-3 parts of sodium carbonate, 1-2 parts of diethylene glycol butyl ether, 1-2 parts of boric acid, 0.3-0.5 parts of diethyl toluenediamine and the balance of water. The aqueous nano-zinc oxide prepared by using the process provided by the invention has high dispersion stability and efficient adhesiveness, and is uniformly distributed on the surface of a metal, so that the metal has high compactness and anti-ion permeability; and due to the added assistant such as the zirconium tetrafluoride and the like, the compactness of a silane absorbing film is increased, the filming quality is improved, the film layer has the characteristics of being strong in adhesion capability, free of cavity and rift, compact and uniform and small in polarization current density, and the production process is environmental-friendly and pollution-free.

Owner:广州易泽得环保科技有限公司

A metal surface silane treatment agent containing sodium ethylenediamine tetramethylene phosphonate and preparation method thereof

ActiveCN103031551BImprove corrosion resistanceExtended service lifeMetallic material coating processesOXALIC ACID DIHYDRATEDispersion stability

The invention discloses a metal surface silane treating agent containing ethylene diamine tetramethylene risedremate sodium. The metal surface silane treating agent is characterized by being a mixture solution prepared from the following ingredients in parts by weight (gram) in each liter of the mixture: 25-33 parts of vinyl triethoxy silane, 30-43 parts of N-phenyl-3-amino propyl trimethoxy silane, 100-190 parts of aqueous nano-zinc oxide, 3-5 parts of ethylene diamine tetramethylene risedremate sodium, 1-2 parts of 1,6-hexamethylendiamine, 4-5 parts of ethanediol, 2-4 parts of oxalic acid, 2-3 parts of zirconium tetrafluoride, 2-3 parts of ammonium molybdate, 1-2 parts of trimethylolpropane, 1-2 parts of citric acid, 0.8-1 parts of pentaerythritol, 0.6-0.9 parts of hydrogen peroxide tertiary butyl and the balance of water. The aqueous nano-zinc oxide prepared by using the process provided by the invention has high dispersion stability and efficient adhesiveness, and is uniformly distributed on the surface of a metal, so that the metal has high compactness and anti-ion permeability; and due to the added assistant such as the zirconium tetrafluoride and the like, the compactness of a silane absorbing film is increased, the filming quality is improved, the film layer has the characteristics of being strong in adhesion capability, free of cavity and rift, compact and uniform and small in polarization current density, and the production process is environmental-friendly and pollution-free.

Owner:江苏台烁烘焙器具有限公司

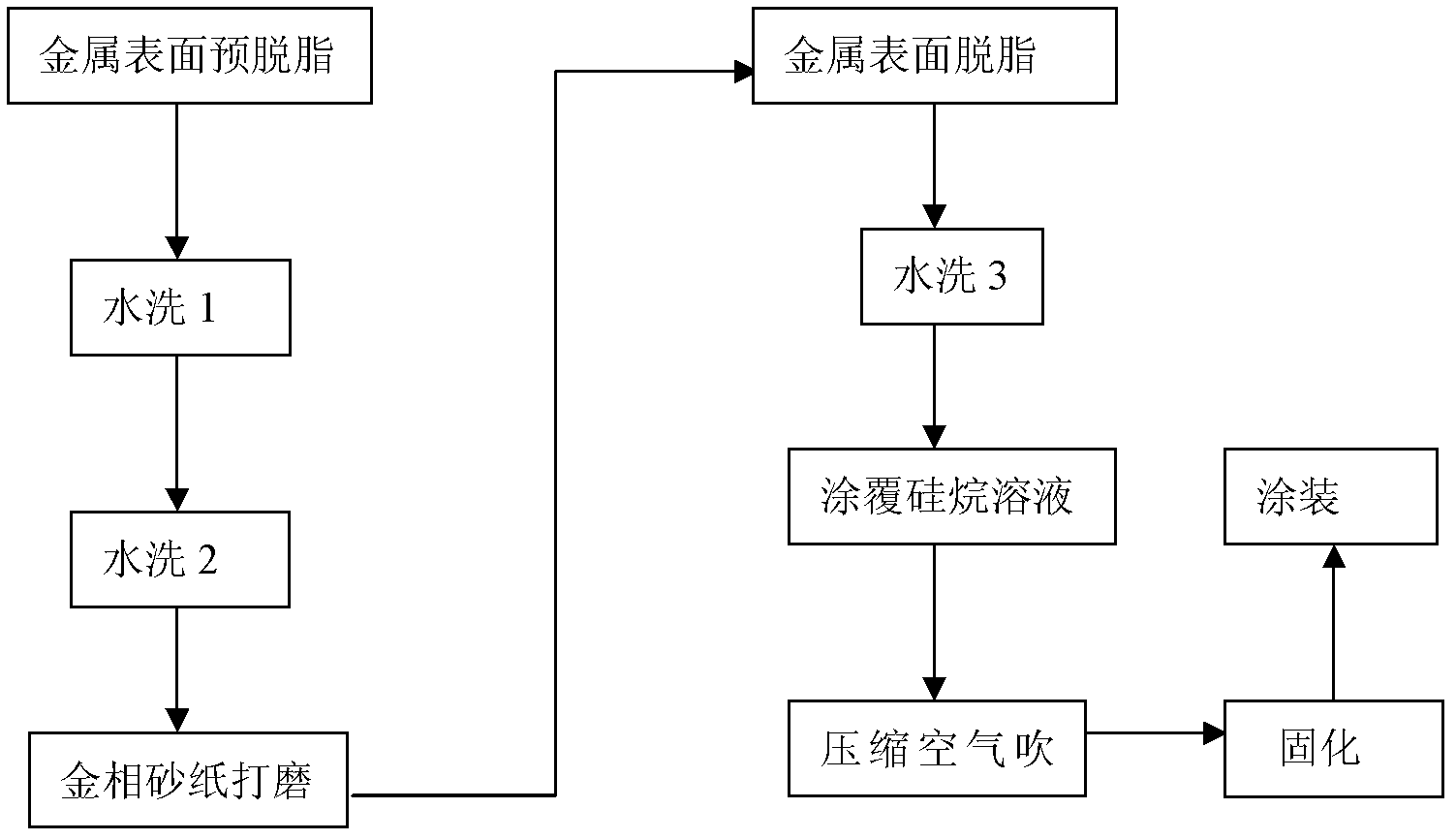

Protecting-treating technology for metal surface

InactiveCN102605365BStrong adhesionImprove adhesionMetallic material coating processesSilanesMaterials science

Owner:蚌埠市钰诚五金工贸有限公司

A metal surface silane treatment agent containing diethanolamine and preparation method thereof

ActiveCN103060787BImprove corrosion resistanceExtended service lifeMetallic material coating processesDiethylene glycol monobutyl etherSilanes

Owner:ANHUI LIUFANG ZHONGLIAN MECHANICAL SHARE

Metallic workpiece pretreatment silane surface treatment agent and preparation method thereof

ActiveCN103031550BImprove corrosion resistancePolarization current density is smallMetallic material coating processesOXALIC ACID DIHYDRATESodium phosphates

The invention discloses a metallic workpiece pretreatment silane surface treatment agent which is a mixed liquor prepared by the following components based on the weight (gram) in each liter of the mixed liquor: 15-20 parts of A-187 silane coupling agent, 3-4 parts of film-forming material, 7-8 parts of KH-570 silane coupling agent, 3-4 parts of acrylic resin emulsion, 3-5 parts of sodium molybdate, 0.05-0.1 parts of lanthanum nitrate, 0.8-1.2 parts of ethylene glycol, 13-15 parts of propylene glycol, 0.1-0.3 parts of oxalic acid, 2-4 parts of phytic acid, 90-95 parts of methyl alcohol, and the balance of deionized water. The silane coupling agent KH572, ammonium molybdate, propylene glycol, borax, sodium tripolyphosphate and the like are taken as the film-forming materials and reaction raw materials to perform polymerization, form the stronger protective film for the metallic workpiece pretreatment, and strengthen the corrosion resistance of the metallic matrix.

Owner:安徽众鑫科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com