Preparation process of metal surface protective treatment fluid

A metal surface and treatment liquid technology, applied in the direction of metal material coating process, etc., can solve the problems of weak adhesion, easy detachment, environmental pollution, etc., and achieve the effect of strong adhesion, enhanced adhesion, and good metal surface pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

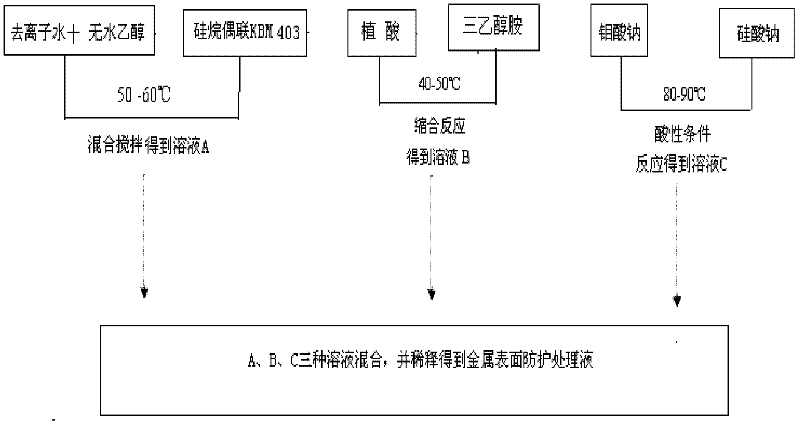

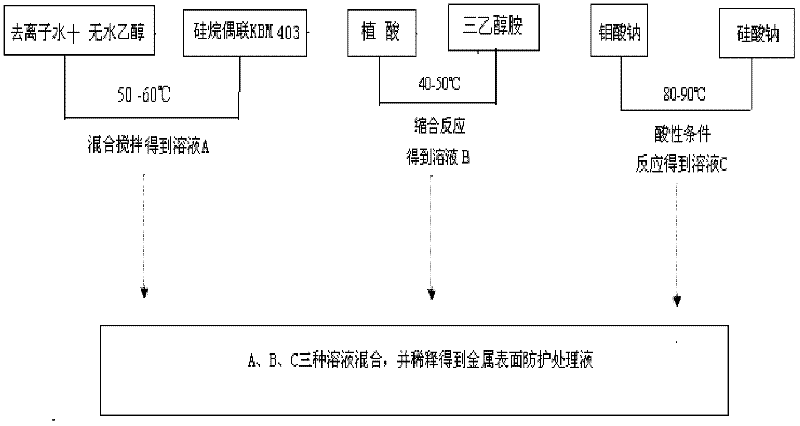

Image

Examples

Embodiment Construction

[0022] The preparation process of 1 liter of metal surface protection treatment liquid specifically comprises the following steps:

[0023] 1) Dilute 100ml of absolute ethanol with deionized water to a concentration of 10%, then add 30 grams of silane coupling agent KBM403 into it, adjust the pH of the solution to 8.0 with glacial acetic acid and sodium bicarbonate, stir and hydrolyze until the solution is clear, Transparent to obtain solution A;

[0024] 2) Mix 2ml of phytic acid and 3ml of triethanolamine, and react at a constant temperature of 45°C for 30min to obtain solution B;

[0025] 3) Mix 5 grams of sodium silicate and 0.3 grams of sodium molybdate, and react at a constant temperature of 80-90°C for 30 minutes under acidic conditions to obtain solution C;

[0026] 4) Mix the three solutions A, B and C prepared above, adjust the pH of the solution to 8.0 with sodium bicarbonate, react at a constant temperature of 55°C, and then adjust the volume to 1 liter with water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com