Metal wire drawing vitrifying liquid and preparation method thereof

A metal wire and mixture technology, applied in the field of pottery fluid, can solve the problems of unstable bath fluid, unenvironmental raw materials, easy occurrence of slag, etc., and achieves the effects of not easy slag, good adhesion, and favorable metal finishing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

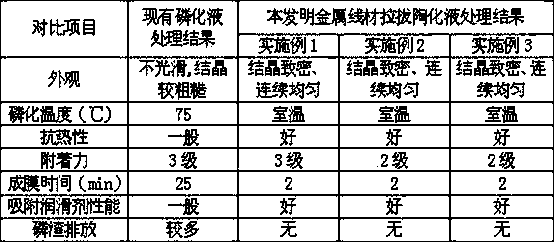

Examples

Embodiment 1

[0039] Metal wire drawing vitrification solution, its raw material composition includes:

[0040] Potassium fluozirconate 20g / L

[0041] Sodium fluotitanate 40g / L

[0042] Silane coupling agent volume content 3.5%

[0043] Phytic acid 2ml / L

[0044] Triethanolamine 5ml / L

[0045] Sodium molybdate 0.3g / L

[0046] Sodium silicate 5.5g / L

[0047] Sodium tartrate 5g / L

[0048] Calcium nitrate 10g / L

[0049] Polyoxyethylene ether substances 5g / L

[0050] Ethanol volume content 10%

[0051] water balance.

[0052] The preparation method of the metal wire drawing vitrification solution comprises the following steps:

[0053] (1) Evenly mix ethanol with a part of water, add silane coupling agent, adjust the pH value to 8 with glacial acetic acid and sodium bicarbonate, and stir until it is clear and transparent to obtain mixture A;

[0054] (2) Mix phytic acid and triethanolamine evenly, and react at a constant temperature at 45°C for 2 hours to obtain mixture B;

[0055] ...

Embodiment 2

[0059] Metal wire drawing vitrification solution, its raw material composition includes:

[0060] Sodium fluozirconate 35g / L

[0061] Potassium Fluotitanate 30g / L

[0062] Silane coupling agent volume content 2%

[0063] Phytic acid 1ml / L

[0064] Triethanolamine 1.5ml / L

[0065] Sodium molybdate 0.2g / L

[0066] Sodium silicate 3g / L

[0067] Sodium tartrate 7.5g / L

[0069] Polyoxyethylene ether substances 4g / L

[0070] Ethanol volume content 6%

[0071] water balance.

[0072]The preparation method of the metal wire drawing vitrification solution comprises the following steps:

[0073] (1) Evenly mix ethanol with a part of water, add silane coupling agent, adjust the pH value to 4 with glacial acetic acid and sodium bicarbonate, and stir until it is clear and transparent to obtain mixture A;

[0074] (2) Mix phytic acid and triethanolamine evenly, and react at a constant temperature at 40°C for 4 hours to obtain mixture B;

[0075] (3)...

Embodiment 3

[0079] Metal wire drawing vitrification solution, its raw material composition includes:

[0080] Sodium fluozirconate 50g / L

[0081] Sodium fluotitanate 35g / L

[0082] Silane coupling agent 5%

[0083] Phytic acid 3ml / L

[0084] Triethanolamine 9ml / L

[0085] Sodium molybdate 0.4g / L

[0086] Sodium silicate 8g / L

[0087] Sodium tartrate 10g / L

[0088] Calcium nitrate 7.5g / L

[0089] Polyoxyethylene ether substances 3g / L

[0090] Ethanol volume content 8%

[0091] water balance.

[0092] The preparation method of the metal wire drawing vitrification solution comprises the following steps:

[0093] (1) Evenly mix ethanol with a part of water, add silane coupling agent, adjust the pH value to 6 with glacial acetic acid and sodium bicarbonate, and stir until it is clear and transparent to obtain mixture A;

[0094] (2) Mix phytic acid and triethanolamine evenly, and react at a constant temperature at 50°C for 3 hours to obtain mixture B;

[0095] (3) Mix sodium silica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com