Silanization processing agent for metal piece individually protection

A technology of silanization treatment and metal parts, applied in the direction of anti-corrosion coatings, coatings, etc., can solve serious and environmental pollution problems, and achieve the effect of improving poor stability, convenient use, and low polarization current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A silanization treatment agent used for the individual protection of metal parts is a mixed solution prepared from the following components, and the parts by weight of each component in each liter of the mixed solution are:

[0032] 1,2-Diethoxysilyl ethane 30g

[0034] Sodium a-sulfo fatty acid methyl ester 0.5g

[0035] EDTA Disodium Salt 0.1g

[0036] Isopropanol 4g

[0037] The balance is ethanol solution.

[0038] Mix the raw materials in the formula ratio and stir evenly.

Embodiment 2

[0040] A silanization treatment agent for the individual protection of metal parts, a mixed solution prepared from the following components, the parts by weight of each component in each liter of the mixed solution are:

[0041] 1,2-Diethoxysilyl ethane 40g

[0043] Sodium a-sulfo fatty acid methyl ester 1g

[0044] EDTA Disodium Salt 0.2g

[0045] Isopropanol 5g

[0046] The balance is ethanol solution.

[0047] Mix the raw materials in the formula ratio and stir evenly.

Embodiment 3

[0049] A silanization treatment agent for the individual protection of metal parts, a mixed solution prepared from the following components, the parts by weight of each component in each liter of the mixed solution are:

[0050] 1,2-Diethoxysilyl ethane 60g

[0051] Sodium molybdate 5g

[0052] Sodium a-sulfo fatty acid methyl ester 1.5 g

[0053] EDTA disodium salt 0.4 g

[0054] Isopropanol 7g

[0055] The balance is ethanol solution.

[0056] Mix the raw materials in the formula ratio and stir evenly.

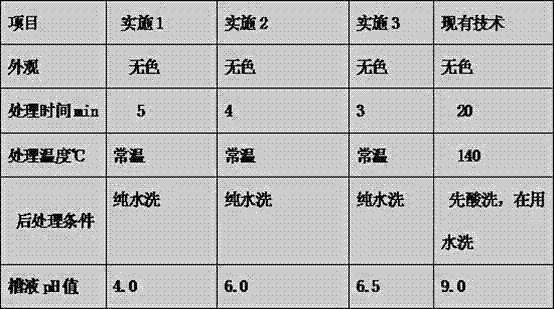

[0057] Contrast the various performance indexes with the metal surface silanization protective treatment agent of the present invention as follows:

[0058]

[0059] It can be seen from the table that the metal surface silanization protective treatment agent of the present invention has the characteristics of energy saving, environmental protection and high efficacy when treating metal workpieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com