Preparation method of active carbon with high specific surface area made from bamboo wood

A high specific surface area, activated carbon technology, applied in the field of comprehensive utilization of resources, can solve the problems of unreasonable utilization of waste bamboo, waste of natural resources, pollution of the environment, etc., and achieve the goal of improving comprehensive utilization, fast adsorption speed and high adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

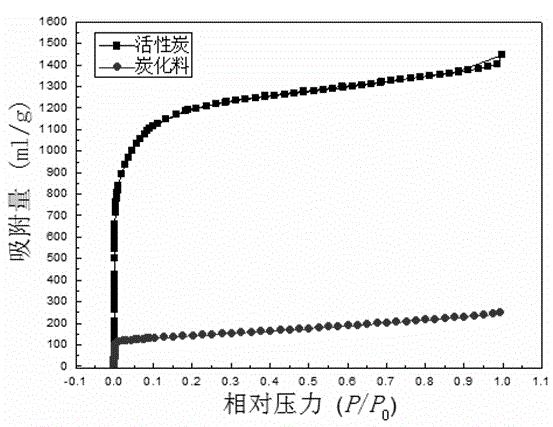

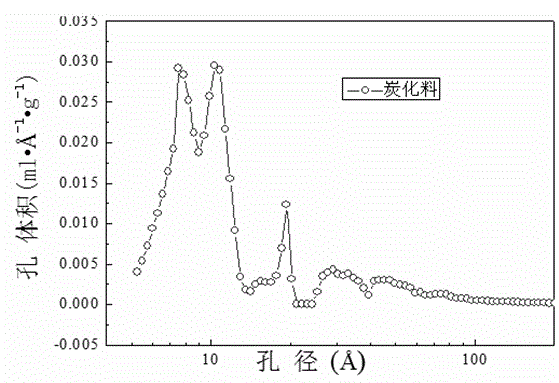

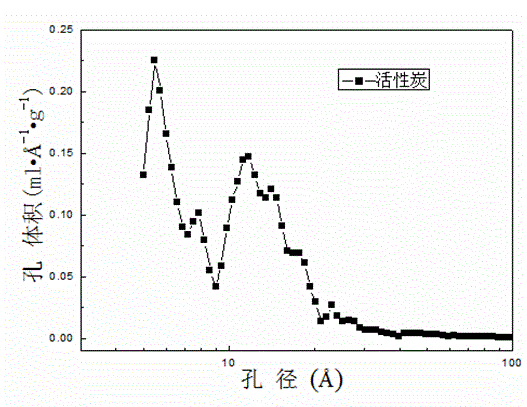

Embodiment 1

[0031] First, clean and remove impurities from the waste bamboo, dry it naturally, put it into a crucible, put it in a high-temperature resistance furnace to raise the temperature to 600°C at 15°C / min, keep it warm for carbonization for 40min, and take it out to obtain the carbonized material after cooling to room temperature with the furnace, and then Crush it to 100-200 mesh as the activation raw material, dry it and package it for later use; mix KOH and carbonized material at a mass ratio of 2.5:1 for solid phase mixing and evenly put it into a ceramic crucible and put it into a microwave device, and pass it into the furnace Nitrogen was used for 2 min to evacuate the air in the furnace, and the microwave power was 10 kW for 8 min; in the last 5 min of heating, CO was quickly blown into the tube connected to the bottom of the ceramic crucible. 2 , and turn on the 300W ultrasonic generator at the same time, after heating, transfer the material to a beaker equipped with tap wa...

Embodiment 2

[0035] First, clean and remove impurities from the waste bamboo, dry it naturally, put it into a crucible, put it in a high-temperature resistance furnace to raise the temperature to 400°C at 5°C / min, keep it warm for 60 minutes, and take it out to obtain the carbonized material after cooling to room temperature with the furnace. It is pulverized to 100-200 meshes as an activation raw material, dried and packaged for later use. Mix KOH and carbonized material in a solid phase at a mass ratio of 2.0:1 and put them into a ceramic crucible and put them into a microwave device. Nitrogen gas was introduced into the furnace for 2 min to evacuate the air in the furnace. Under the condition of microwave power 5 kW Heating at low temperature for 10 minutes, in the last 4 minutes of heating, quickly blow CO2 through the tube connected to the bottom of the ceramic crucible 2 , and open the 600W ultrasonic generator at the same time, after heating, the material is transferred to a beaker ...

Embodiment 3

[0038] First, clean and remove impurities from the waste bamboo, dry it naturally, put it into a crucible, put it in a high-temperature resistance furnace to raise the temperature to 500°C at 10°C / min, keep it warm for carbonization for 50 minutes, and take it out to obtain the carbonized material after cooling to room temperature with the furnace, and then Grind it to 100-200 mesh as the activation raw material, dry it and package it for later use; mix KOH and carbonized material in a solid phase with a mass ratio of 3.0:1 and evenly put it into a ceramic crucible and put it into a microwave device, and pass it into the furnace Nitrogen was used for 2 minutes to evacuate the air in the furnace, and heated for 12 minutes under the condition of microwave power 8 kW. In the last 7 minutes of heating, CO was quickly blown into the tube connected to the bottom of the ceramic crucible. 2 , and open the 500W ultrasonic generator at the same time, after heating, the material is transf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com