A production process of high-strength green silicon carbide micropowder and its special grinding machine

A technology of green silicon carbide micropowder and production process, which is applied in the production process of high-strength green silicon carbide micropowder and its special grinding machine field, can solve the problems of affecting strength and cutting force, excessive grinding, and different particle size, etc. Improved efficiency, strong grinding force, and reduced over-grinding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

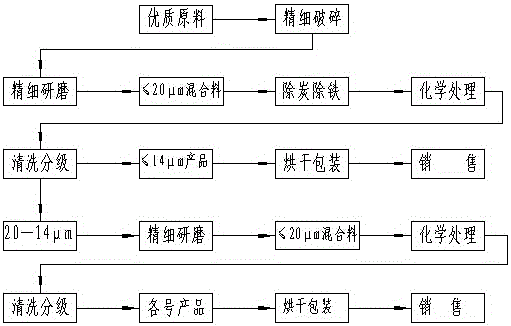

[0020] Such as figure 1 Shown, the present invention comprises and comprises following processing step:

[0021] 1. Fine crushing: the green silicon carbide raw material with a content of 98.5% is finely crushed with a roller crushing device to a loose material with a particle size of 0.2 mm or less, and the loose material particles have sharp edges and corners;

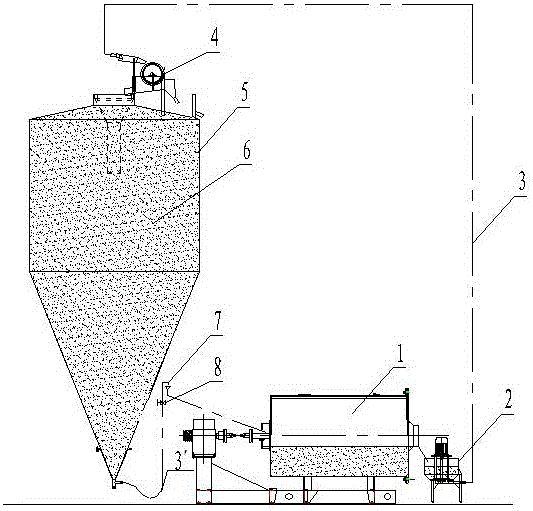

[0022] 2. Wet grinding: the loose material prepared in step 1 is wet-grinded with a special grinder, and ground to a fine mixture with a particle size of 20 microns or less;

[0023] 3. Purification and classification: the 20 micron fine mixture prepared in step 2 is firstly subjected to carbon removal and iron removal treatment, and then classified through a classification tank, wherein the fine powder with a particle size of 10 micron is separated and can be prepared Wire cutting core material or polishing powder, and the rest of the mixture with a particle size of 10-20 microns is left for the next process step; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com