Rubber for automobile absorber

A technology for automobile shock absorbers and rubber, applied in the field of rubber materials, can solve problems such as poor shock absorption performance, and achieve the effects of reasonable formula, excellent aging resistance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

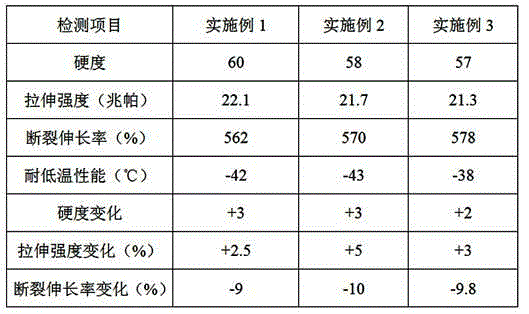

Examples

Embodiment 1

[0014] The rubber used for automobile shock absorbers in this embodiment is prepared from the following raw materials in parts by weight: 15 parts of silicone rubber, 10 parts of butadiene rubber, 28 parts of polyurethane rubber, 2 parts of plasticizer, 1 part of anti-aging agent, and 5 parts of accelerator , 0.5 parts of nano-zinc oxide, 1 part of benzoyl peroxide, 5 parts of rosin, and 2 parts of sulfur.

Embodiment 2

[0016] The rubber used for automobile shock absorbers in this embodiment is prepared from the following raw materials in parts by weight: 25 parts of silicone rubber, 15 parts of butadiene rubber, 20 parts of polyurethane rubber, 4 parts of plasticizer, 4 parts of anti-aging agent, and 2 parts of accelerator , 2 parts of nano-zinc oxide, 3 parts of benzoyl peroxide, 7 parts of rosin, and 7 parts of sulfur.

Embodiment 3

[0018] The rubber used for automobile shock absorbers in this embodiment is prepared from the following raw materials in parts by weight: 30 parts of silicone rubber, 20 parts of butadiene rubber, 35 parts of polyurethane rubber, 6 parts of plasticizer, 7 parts of anti-aging agent, and 8 parts of accelerator , 4 parts of nano-zinc oxide, 5 parts of benzoyl peroxide, 10 parts of rosin, and 10 parts of sulfur.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com