Polyphenylene sulfide composite material and preparation method thereof

A polyphenylene sulfide and composite material technology, applied in the field of polymer materials, can solve problems such as easy accumulation of static charges, affecting production, life or work, fire or explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

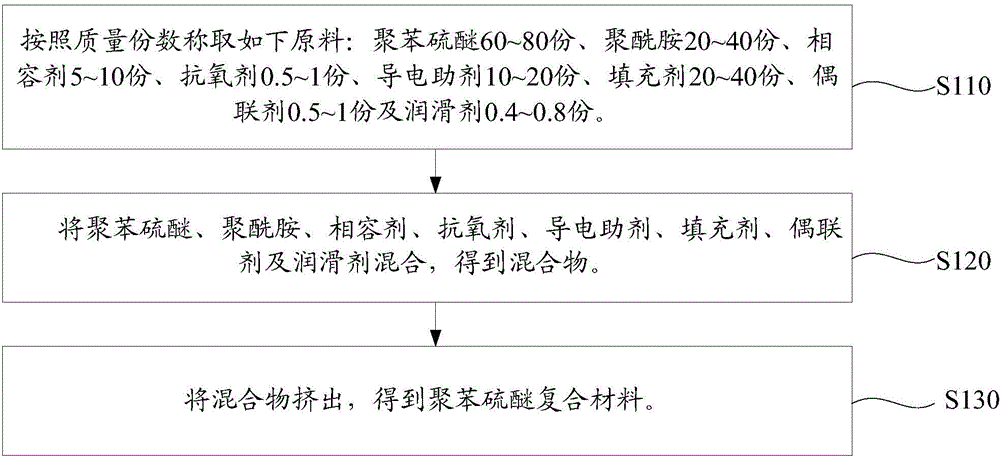

[0037] Such as figure 1 As shown, the preparation method of polyphenylene sulfide composite material in one embodiment can be used to prepare the above-mentioned polyphenylene sulfide. The preparation method of this polyphenylene sulfide comprises the steps:

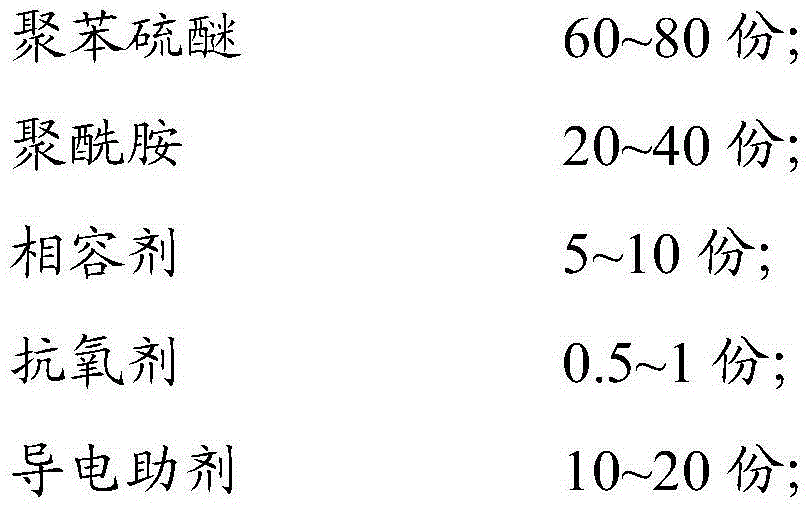

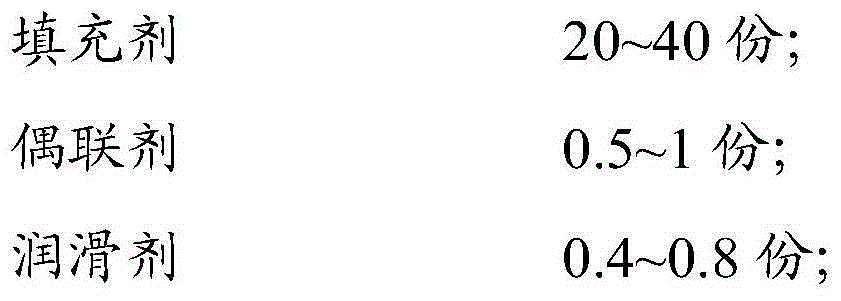

[0038] Step S110: Weigh the following raw materials in parts by mass: 60-80 parts of polyphenylene sulfide, 20-40 parts of polyamide, 5-10 parts of compatibilizer, 0.5-1 part of antioxidant, 10-20 parts of conductive additive 20-40 parts of filler, 0.5-1 part of coupling agent and 0.4-0.8 parts of lubricant.

[0039] Wherein, the polyphenylene sulfide may be polyphenylene sulfide with a brand name of 1140A6NC from Japan Baoli Company.

[0040] The polyamide is preferably polyamide 46, eg PA46 of type G2000E from Teijin Corporation.

[0041] Wherein, the compatibilizer is styrene-ethylene-butadiene-styrene block copolymer grafted maleic anhydride (SEBS-g-MAH).

[0042] The antioxidant is preferably N,N-1,6-hexylene-bis[...

Embodiment 1

[0054] The preparation steps of the polyphenylene sulfide composite material of the present embodiment are as follows:

[0055] (1) Take the following raw materials according to the mass percentage:

[0056]

[0057] (2) Dry mix polyphenylene sulfide, polyamide 46, compatibilizer, antioxidant 1098, superconducting furnace carbon black, alkali-free glass fiber, silane coupling agent and oxidized polyethylene wax in a high-speed mixer 12 minutes, obtain mixture, wherein, compatibilizer is styrene-ethylene-butadiene-styrene block copolymer graft maleic anhydride (SEBS-g-MAH), wherein, the monofilament diameter of alkali-free glass fiber 9 to 17 microns.

[0058] (3) Put the mixture in a twin-screw extruder, melt extrude, cool, pelletize and package to obtain the polyphenylene sulfide composite material of this embodiment. Among them, the screw speed of the extruder is 400rpm, the temperature of the first zone of the twin-screw extruder is 230°C, the temperature of the second...

Embodiment 2

[0062] The preparation steps of the polyphenylene sulfide composite material of the present embodiment are as follows:

[0063] (1) Take the following raw materials according to the mass percentage:

[0064]

[0065] (2) Dry mix polyphenylene sulfide, polyamide 46, compatibilizer, antioxidant 1098, superconducting furnace carbon black, alkali-free glass fiber, silane coupling agent and oxidized polyethylene wax in a high-speed mixer 10 minutes, obtain mixture, wherein, compatibilizer is styrene-ethylene-butadiene-styrene block copolymer grafted maleic anhydride (SEBS-g-MAH), wherein, the monofilament diameter of alkali-free glass fiber 9 to 17 microns.

[0066] (3) Put the mixture in a twin-screw extruder, melt extrude, cool, pelletize and package to obtain the polyphenylene sulfide composite material of this embodiment. Among them, the screw speed of the extruder is 400rpm, the temperature of the first zone of the twin-screw extruder is 230°C, the temperature of the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com