Method for preparing metaplexis japonica juice fibers

A technology of radish and pulp, which is applied in the field of textile fibers, can solve the problems of high development costs and limited raw material sources, and achieve the effects of low development costs, wide fiber uses and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

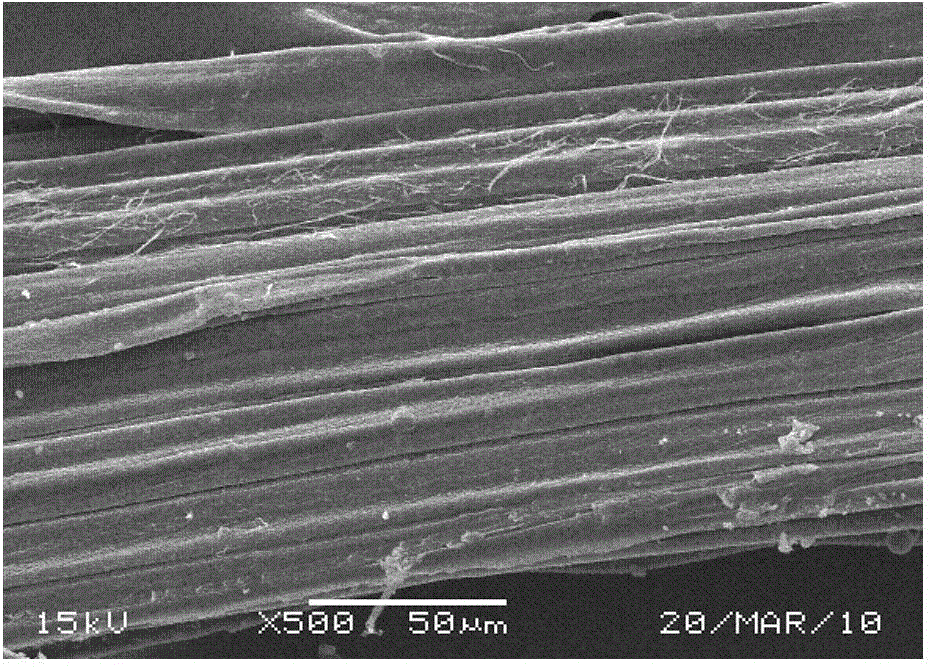

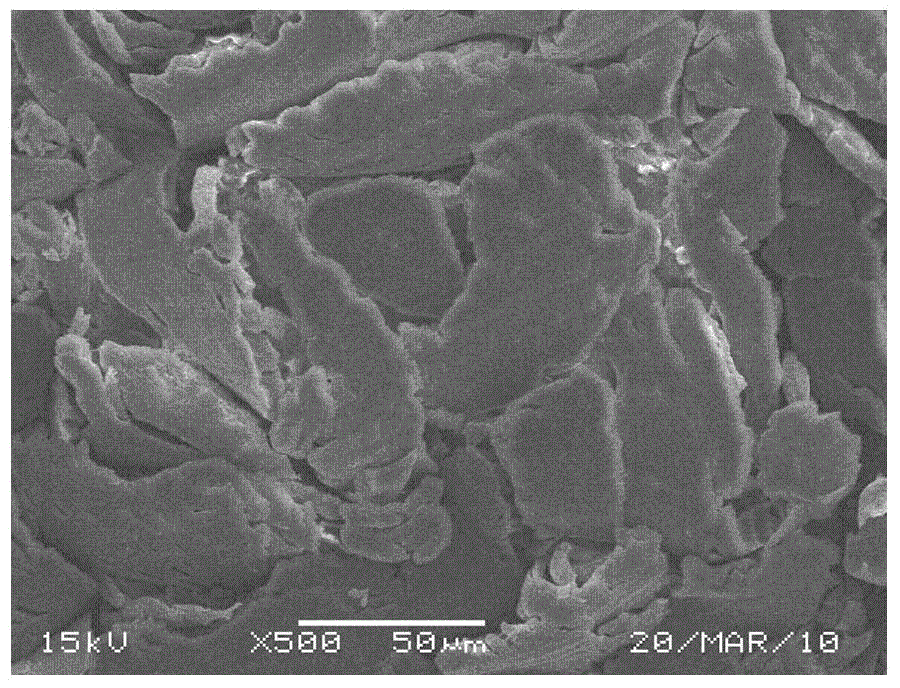

Image

Examples

Embodiment 1

[0038] A preparation method of radish juice fiber, comprising the following steps:

[0039] 1) Arranging and cutting off the radish stems to become 0.45 meters long, and tying them into small bundles, 120 per bundle;

[0040] 2) Put the bundle-shaped radish stalks into water for immersion, the water temperature is about 18°C, and immerse for 30 days;

[0041] 3) Take it out from the water, wash and dry it in the sun, and squeeze the broken stems with a small paddle;

[0042] 4) Use a double-drum impurity separator to separate broken stems, impurity dander, etc. from radish juice fibers;

[0043] 5) The obtained radish pulp juice fiber was scoured for 30 minutes in a caustic soda solution with a mass concentration of 0.5%; the bath ratio was 1:5, and the temperature was 95° C.;

[0044] 6) Cooling after washing with cold water;

[0045] 7) At room temperature, soak for 10 minutes with a sulfuric acid solution with a mass concentration of 0.1%;

[0046] 8) Wash with clean wa...

Embodiment 2

[0053] A preparation method of radish juice fiber, comprising the following steps:

[0054] 1) Arranging and cutting the radish stems into 0.6 meters long, and tying them into small bundles, 100 in each bundle;

[0055] 2) Put the bundle-shaped radish stalks into water for immersion, the water temperature is about 21°C, and immerse for 40 days;

[0056] 3) Take it out from the water, wash and dry it in the sun, and squeeze the broken stems with a small paddle;

[0057] 4) Use a double-drum impurity separator to separate broken stems, impurity dander, etc. from radish juice fibers;

[0058] 5) Scouring the obtained radish juice fiber for 40 minutes in a caustic soda solution with a mass concentration of 1%; the liquor ratio is 1:10, and the temperature is 95°C;

[0059] 6) Cooling after washing with cold water;

[0060] 7) At room temperature, soak for 20 minutes with a sulfuric acid solution with a mass concentration of 0.16%;

[0061] 8) Wash with clean water at room temper...

Embodiment 3

[0068] 1) Arranging and cutting off the radish stems to become 0.5 meters long, and tying them into small bundles, 110 in each bundle;

[0069] 2) Put the bundle-shaped radish stalks into water for immersion, the water temperature is about 20°C, and immerse for 35 days;

[0070] 3) Take it out from the water, wash and dry it in the sun, and squeeze the broken stems with a small paddle;

[0071] 4) Use a double-drum impurity separator to separate broken stems, impurity dander, etc. from radish juice fibers;

[0072] 5) The obtained radish juice fiber was scoured in a caustic soda solution with a mass concentration of 0.8% for 35 minutes; the bath ratio was 1:7.5, and the temperature was 92°C;

[0073] 6) Cooling after washing with cold water;

[0074] 7) At room temperature, soak for 15 minutes with a sulfuric acid solution with a mass concentration of 0.14%;

[0075] 8) Wash with clean water at room temperature to remove some residual dander and gum;

[0076] 9) Scouring i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com