A Construction Technology of Proton Waste Beam Station

A proton and construction method technology, which is applied in the field of proton waste beam station construction, can solve the problems of radiation pollution, high cost, dryness and no wet stains, etc., and achieves the effect of strengthening anti-deformation ability, realizing radiation shielding, and avoiding radiation expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0039] A proton waste beam station construction technology, characterized in that it comprises the following steps:

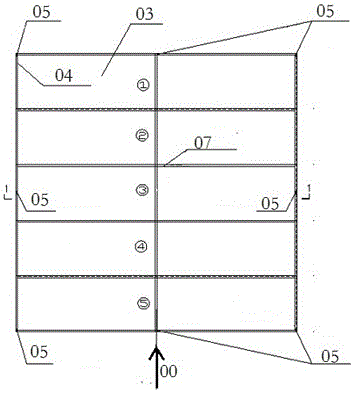

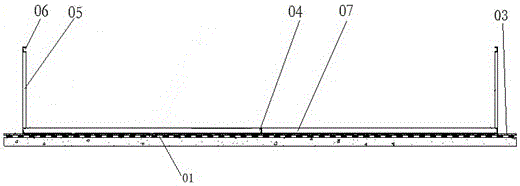

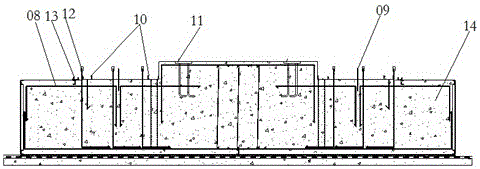

[0040] a. Install the outsourcing waterproof steel plate under the bottom plate (such as Figure 1-2 As shown): first measure the setting-out position, and then after the waterproof coiled material cement mortar protective layer 01 is completed, lay the fully welded galvanized steel plate 03 on it. The laying method of the steel plate 03 is: the long side of the steel plate 03 is perpendicular to the bundle The flow direction is 00, the short side is parallel to the beam direction 00, press from start to Lay the steel plate one by one in order, the steel plate gap is 3mm, after the laying is completed, the galvanized layer at the welding position is ground off, the full welding connection is made, the weld seam size is 4mm, after the weld seam passes the flaw detection, the surface of the weld seam is coated with zinc-rich paint; Weld the horizontal channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com