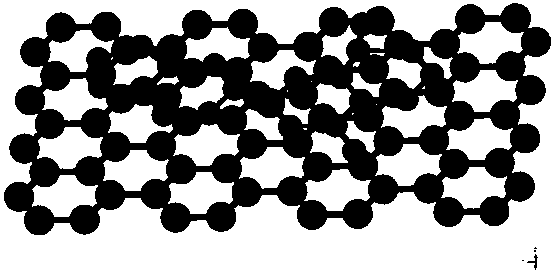

A method for stable doping to reduce the sheet resistance of graphene films

A technology of graphene film and square resistance, which is applied in the direction of resistors, resistance manufacturing, circuits, etc., can solve the problems of rising square resistance, affecting the quality of graphene, limiting the application of graphene film, etc., to reduce square resistance and facilitate patterns Chemical treatment, promote the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

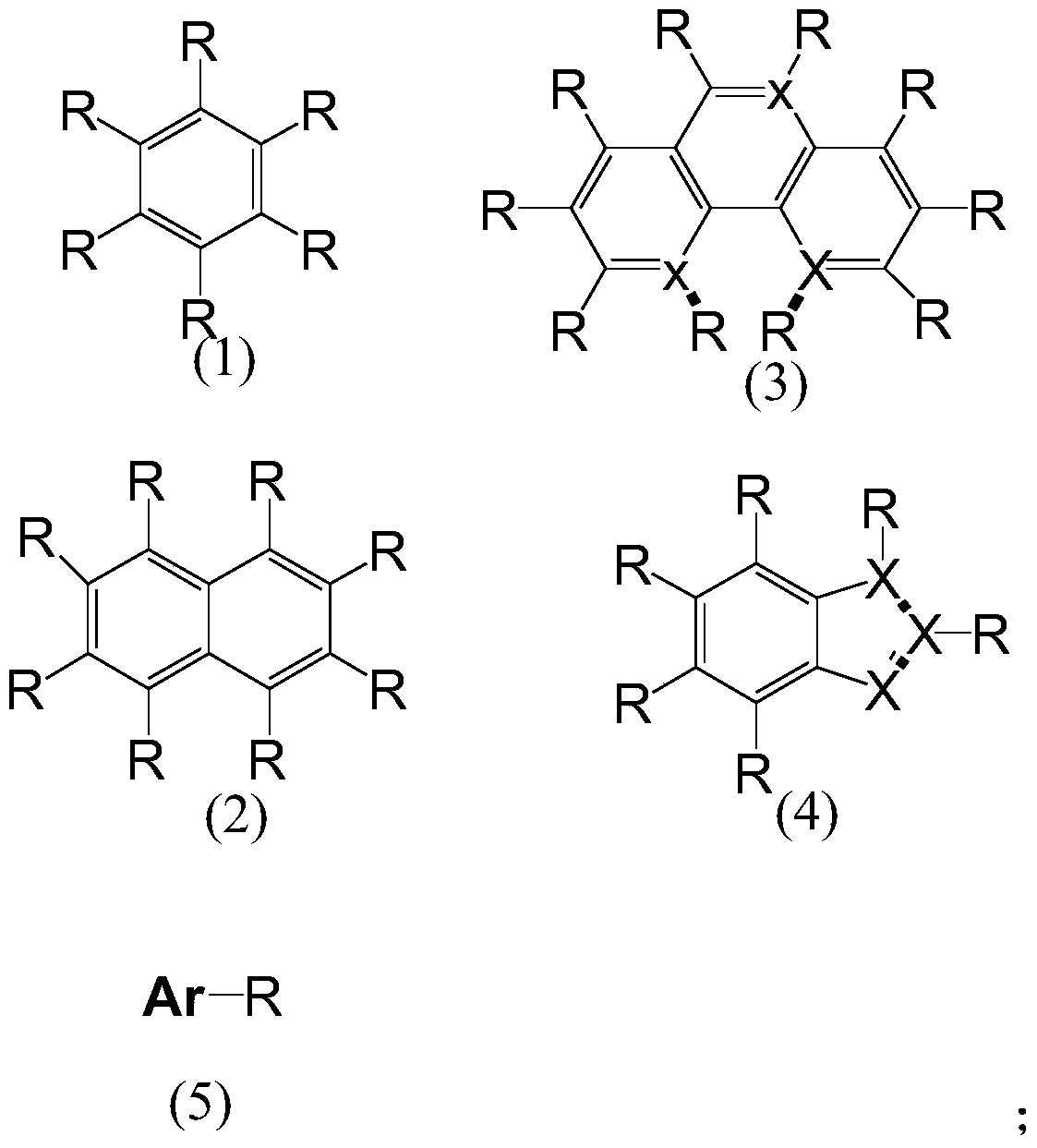

Embodiment 1

[0025] Prepare the doping reagent into a 0.01-1mol / L ethanol solution, soak the graphene film transferred on the substrate into the solution for 80 minutes, take it out and soak it in clean water for 1 minute, and dry it with high-purity nitrogen. Then heated at 80°C for 60min. The square resistance of graphene dropped from 520Ω / □ to 170-220Ω / □. Available doping reagent structures are as follows:

[0026]

[0027]

Embodiment 2

[0029] Prepare the doping reagent into a 0.01-1mol / L carbon disulfide solution, soak the graphene film transferred on the substrate into the solution for 20 minutes, take it out and soak it in a solvent for 240 minutes, and dry it with high-purity nitrogen. It was then heated at 8 °C for 240 min. The square resistance of graphene dropped from 550Ω / □ to 190-254Ω / □. Available doping reagent structures are as follows:

[0030]

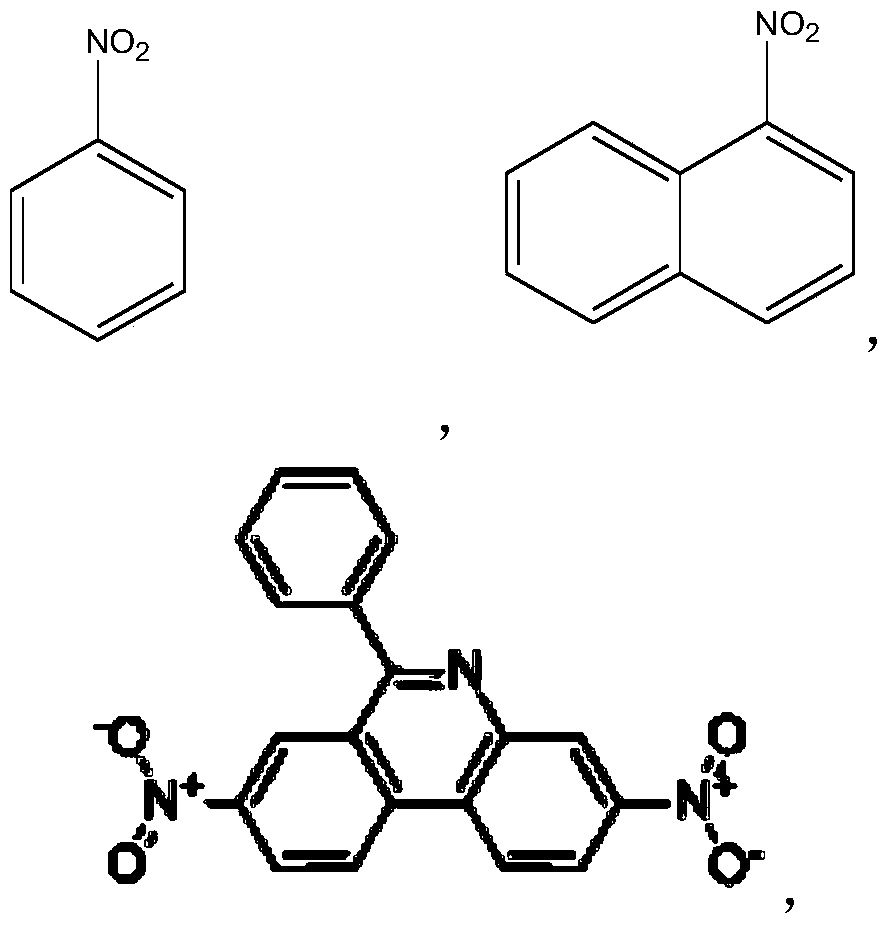

Embodiment 3

[0032] The doping reagent is prepared into a solution of 0.01-1 mol / L, dropped on the graphene film and left for 20 minutes, and the graphene film is soaked in a solvent (including aqueous solution, ethanol solution, isopropanol, etc.) for 30 minutes. The square resistance of graphene dropped from 515Ω / □ to 225-245Ω / □.

[0033] Available doping reagent structures are as follows:

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com