Image enhancer

A technology of image intensifier and outer casing, which is applied in the field of imaging, can solve the problems of unstable optical path, bulky, difficult installation, etc., and achieve the effect of simple structure, reduced overall weight, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

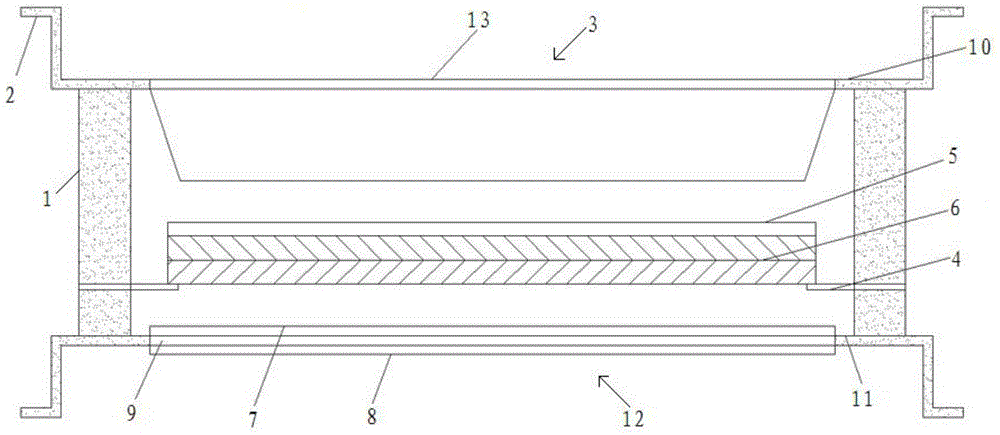

[0023] Such as figure 1 As shown, the present invention includes an outer casing 1 of cylindrical structure, the upper end of the outer casing 1 is provided with a top cover 10, and the bottom end of the outer casing 1 is provided with a bottom cover 11, and the top cover 10 and the bottom cover 11 are all sealed. Installed on the outer casing 1, the top cover 10 is provided with an input window 3, the fiber optic panel 13 is sealed and installed on the input window 3, the fiber optic panel 13 is covered with a high-transmittance film, and the bottom cover 11 There is an output window 12 corresponding to the input window 3, and the optical fiber panel 2 9 is sealed and installed on the output window 12. The side of the optical fiber panel 9 close to the inner cavity of the outer casing 1 is coated with a phosphor layer 7, and the optical fiber The other side of the panel two 9 is covered with a lead glass layer 8, and a microchannel plate 6 is arranged at a position above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com