Preparation method of silica-based laminated solar cell

A solar cell and stacking technology, applied in the field of solar cells, can solve the problems of low solar energy conversion efficiency of solar cells, and achieve the effects of good compatibility and low development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

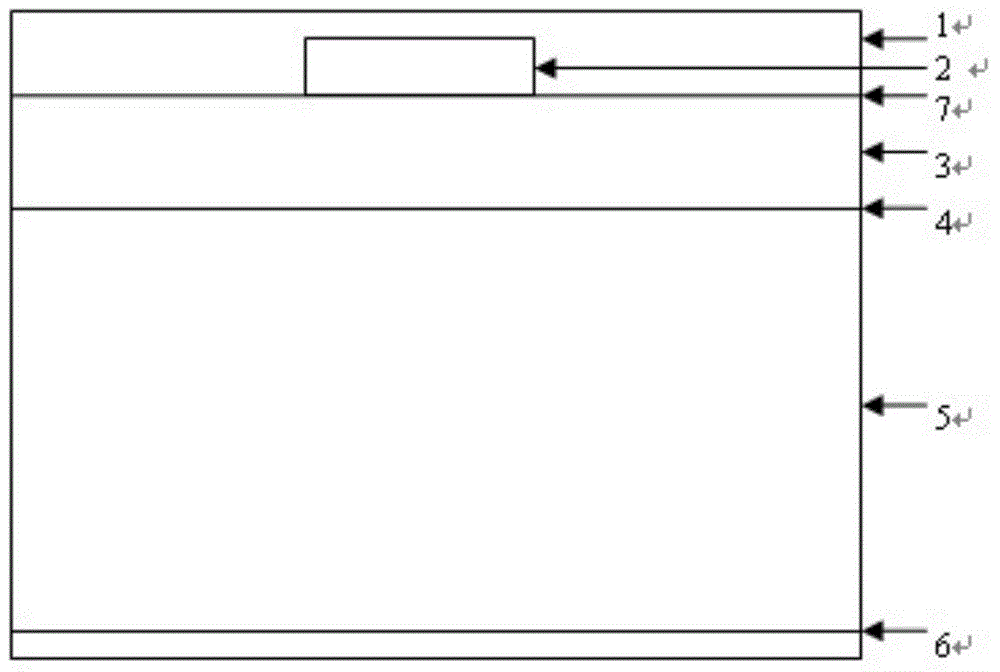

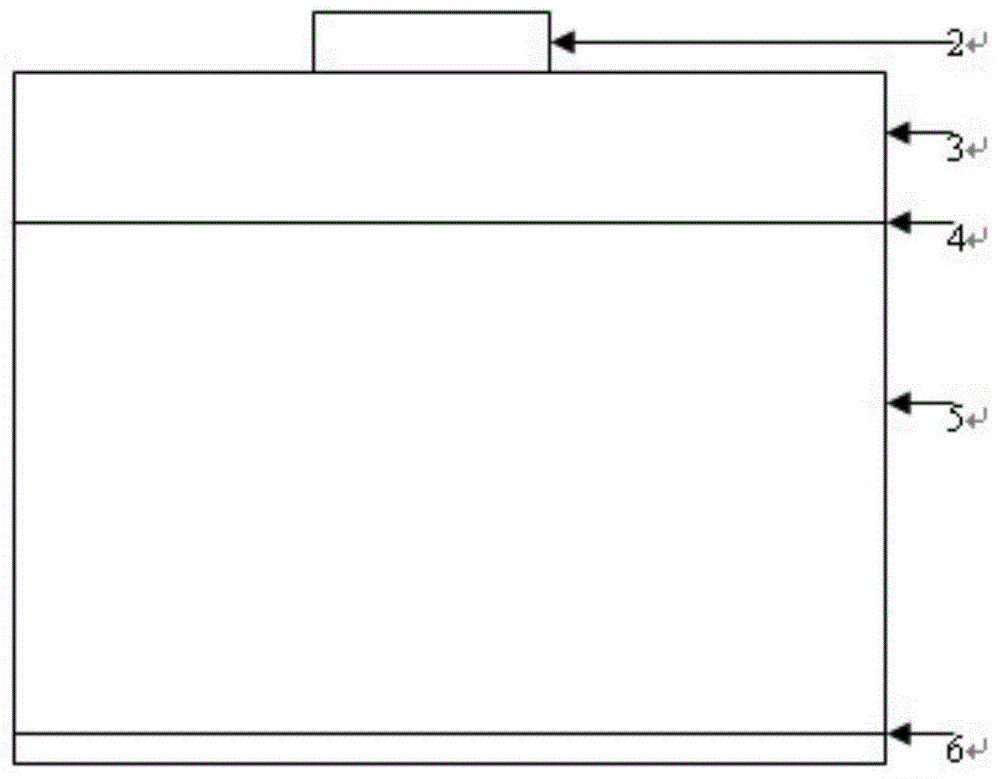

Method used

Image

Examples

Embodiment 1

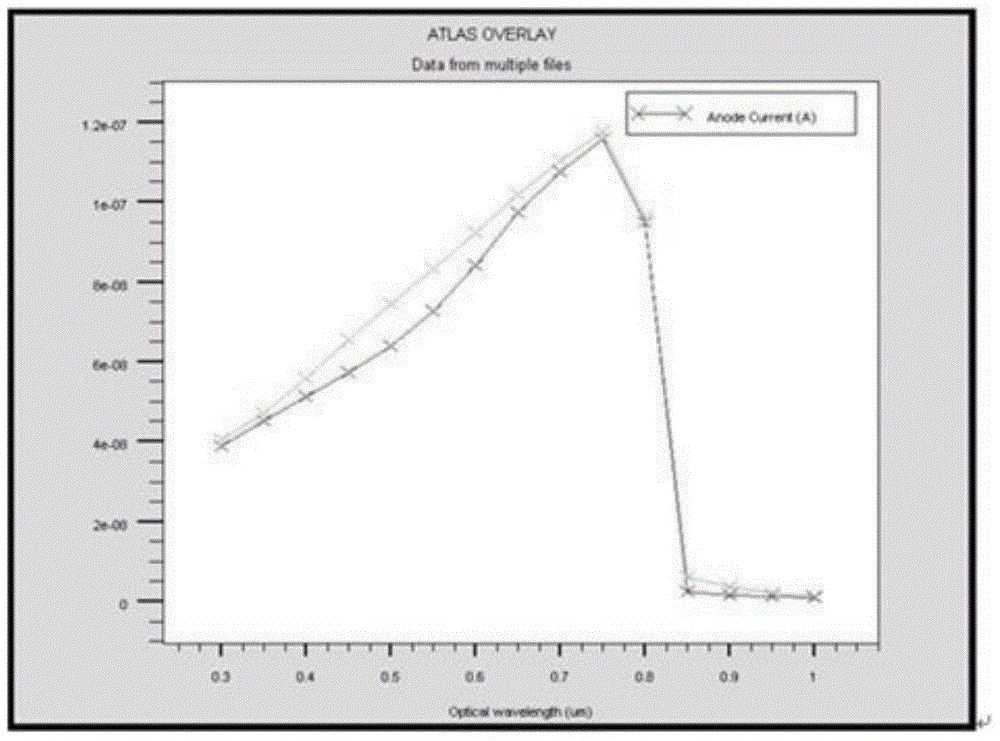

[0022] Embodiment 1, battery spectral response simulation test.

[0023] The results of this test can be found in image 3 ,from image 3 It can be seen that the change trend of the spectral response of the two batteries is the same, both increase with the increase of the wavelength in the 300-850nm band, and the spectral response intensity decreases rapidly after 850nm. From the change trend of spectral response, the main part of solar energy absorbed by the solar cell of the present invention is still in the polycrystalline silicon substrate. The spectral response peak at 850nm is related to the forbidden band width of polysilicon, that is, this wavelength is equivalent to the forbidden band width of polysilicon.

[0024] The response intensity of the battery in the invention is stronger than that of the single-junction polycrystalline silicon solar battery in the whole spectral region, especially in the 400-600nm band and the band after 850nm. It can be seen from the in...

Embodiment 2

[0025] Embodiment 2, open circuit voltage simulation experiment.

[0026] The results of this test can be found in Figure 5 , in the 300-850nm band, the open circuit voltage of the battery of the present invention is basically the same as that of the single-junction polycrystalline silicon battery, and both increase with the increase of the wavelength. But in the 850nm band, the voltage of the battery of the present invention is greatly improved compared with the single-junction polycrystalline silicon battery. This is because from the battery structure, the electrodes of the two batteries are all deposited on polysilicon, so the open circuit voltage does not change much before 850nm, but the spectral response in the long-wave band is stronger than that of the single-junction polysilicon battery, so the present invention The voltage of the battery in the long-wave band is stronger than that of the single-junction polycrystalline silicon battery.

Embodiment 3

[0027] Example 3, the effect of α-si film thickness on the spectral response of the battery The results of this test can be found in Image 6 , Image 6 Shown in the α-si thin film thickness of 0.01, 0.1, 0.5, 1μm and the spectral response of polycrystalline silicon cells. It can be seen from the figure that as the thickness of the α-si (amorphous silicon) film increases, the spectral response intensity in the 300-850nm band gradually decreases, and after the wavelength of 850nm, the spectral response gradually increases with the increase of the film thickness. This shows that as the thickness increases, the incident light of shorter wavelength is absorbed by the film itself, resulting in a decrease in the light intensity reaching the substrate, and the spectral response decreases with the increase of film thickness. However, since the long wave cannot be absorbed by the film with a wide band gap, the absorption of the long wave by the polysilicon substrate increases, so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com