Group III semiconductor luminescent device

A technology of light-emitting devices and semiconductors, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problem of excessive etching of the active layer, achieve the effect of increasing the light-emitting area and improving the photoelectric characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

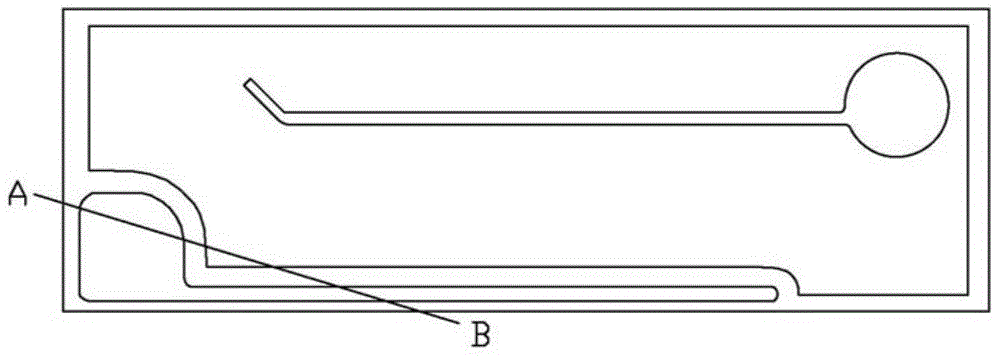

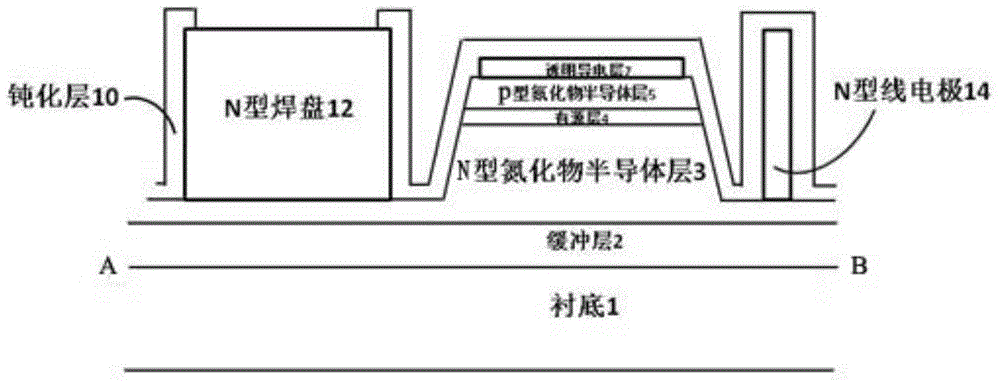

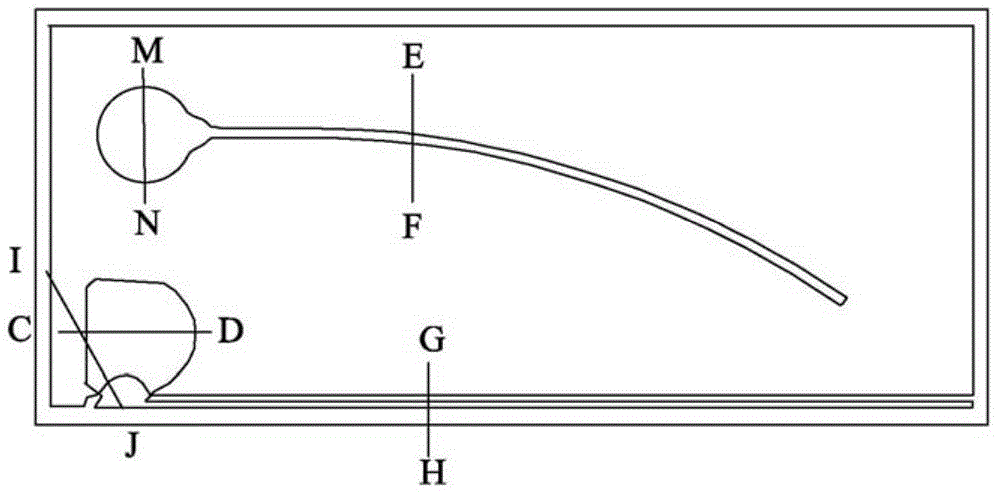

[0085] like image 3 As shown, it is a top view of the Group III semiconductor light-emitting device provided in this embodiment, Figure 4a-Figure 4c for image 3 The cross-sectional view of the N-type pad in the I-J direction to the N-type line electrode; Figure 5a to Figure 5d for image 3 The cross-sectional view of the P-type pad in the M-N direction; Figure 6a and Figure 6b for image 3 The cross-sectional view of the N-type pad in the C-D direction; Figure 7a-7d for image 3 The cross-sectional view of the P-type wire electrode in the E-F direction; Figures 8a-8d for image 3 The cross-sectional view of the N-type wire electrode in the G-H direction; Figure 9 is a top view of the N-type wire electrode and the active layer below it; Figure 10 for Figure 9 A cross-sectional view of the active layer under the N-type line electrode being reduced; Figure 11a and Figure 11b It is a wire bonding pad-insulating layer-transparent conductive layer and its e...

Embodiment 2

[0108] On the basis of embodiment 1, image 3 is a top view of the Group III semiconductor light-emitting device provided in this embodiment, and Figure 4a to ~ Figure 8d respectively image 3 cross-sectional view.

[0109] Figure 5a-5d , Figure 6a , Figure 6b respectively image 3 The cross-sectional view of the P-type pad 11 and the N-type pad 12 along the M-N and C-D section lines, it can be seen that the P-type pad 11 and the N-type pad 12 are all located above the active layer 4, wherein Figure 5a , Figure 5b , Figure 6a , Figure 6b The structure can be located anywhere above the insulating layer, and it is easier to design the mask pattern because it does not affect the current distribution.

[0110] Figure 5a , Figure 5b , Figure 6a and Figure 6b The bottom of the P-type pad 11 and N-type pad 12 is an insulating layer, so it does not participate in the current distribution. Therefore, only the P-type wire electrode 13 and the N-type wire elect...

Embodiment 3

[0114] like Figure 12 As shown, the Group III nitride semiconductor light-emitting device provided in this embodiment includes a substrate 1, a buffer layer 2, an n-type nitride semiconductor layer 3, an active layer 4, and a p-type nitride semiconductor layer arranged sequentially from bottom to top. layer 5, transparent conductive layer 7 and insulating layer 15.

[0115] The five layers of the substrate 1 , the buffer layer 2 , the n-type nitride semiconductor layer 3 , the active layer 4 and the p-type nitride semiconductor layer 5 constitute the structure of the boss 16 .

[0116] The upper surface of the boss 16 is the upper surface of the p-type nitride semiconductor layer.

[0117] An N-type wire electrode 14 is provided on the boss, and the N-type wire electrode 14 is in contact with the n-type nitride semiconductor layer 3 .

[0118] The active layer 4 below the N-type line electrode 14 is partially etched away (see Figure 9 ).

[0119] The N-type wire electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com