A kind of urate-lowering peptide chelated calcium and its preparation method and application

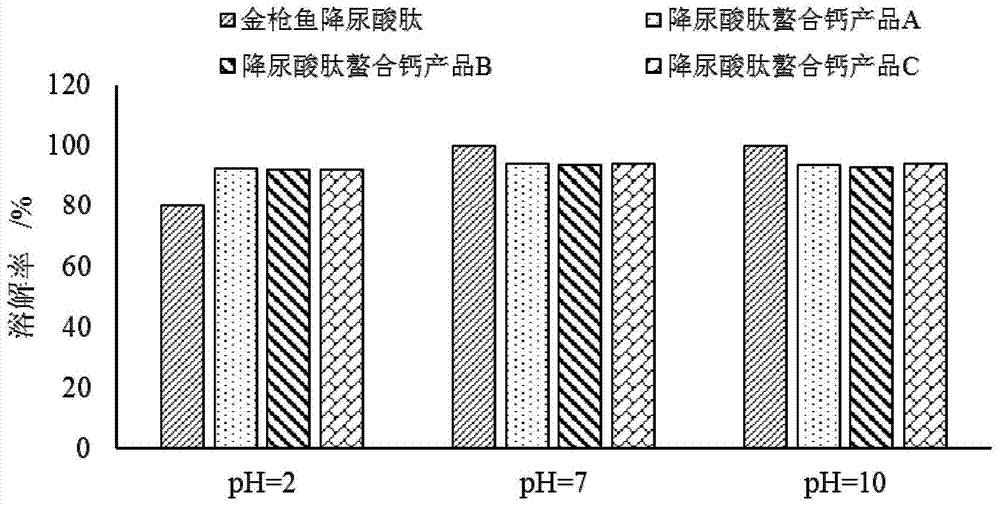

A technology of uric acid peptide and chelated calcium, which is applied in food science and other fields, can solve the problems of synovial fluid loss of lubrication and protection of joints, poor joint load-bearing capacity, and worn-out calcium in joints, and achieve excellent uric acid reduction, low production cost, and calcium The effect of high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method for chelated calcium of urate-lowering peptide, comprising the following steps:

[0043] (1) Pretreatment of saury: remove the head and viscera of saury, clean it, grind it through a meat grinder, add water with 3 times the mass of minced saury meat, heat and stir at 50°C for 1.0 hour, then add HCl solution (0.5mol / L) to adjust the pH of the system to 4.2, continue stirring and heating for 1.5 hours, centrifuge (5000r / min, 15-20min) to separate, discard the supernatant and the upper layer of grease, and take the precipitate.

[0044] (2) Preparation of uric acid-lowering peptide: Add 1 times the mass of water to the saury sediment, use 0.5mol / L NaOH solution to adjust the pH of the system to 7.0, raise the temperature of the saury slurry to 55°C, and then add 0.6% of Novozymes’ Alcalase 2.4L and 1.2% Novozymes’ flavor protease of saury sediment mass were hydrolyzed at 55°C for 6 hours, heated at 95°C for 15min, and then heated at 5000r / min Centrifu...

Embodiment 2

[0049] A preparation method for chelated calcium of urate-lowering peptide, comprising the following steps:

[0050] (1) Pretreatment of saury: remove the head and viscera of saury, clean it, grind it through a meat grinder, add water 4 times the weight of the minced meat of saury, heat and stir at 40°C for 2.0 hours, then add HCl solution (0.5mol / L) to adjust the pH of the system to 4.2, continue stirring and heating for 1.0 hour, centrifuge (5000r / min, 15-20min) to separate, discard the supernatant and the upper layer of grease, and take the precipitate.

[0051] (2) Preparation of uric acid-lowering peptide: add 1.5 times the mass of water to the saury sediment, use 0.5mol / L NaOH solution to adjust the pH of the system to 7.0, raise the temperature of the saury slurry to 50°C, and then add 0.8% of Novozymes’ Alcalase 2.4L and 1.5% Novozymes’ flavor protease of saury sediment quality were hydrolyzed at 50°C for 9 hours, heated at 95°C for 15min, and then heated at 5000r / min ...

Embodiment 3

[0056] A preparation method for chelated calcium of urate-lowering peptide, comprising the following steps:

[0057] (1) Pretreatment of saury: remove the head and viscera of saury, clean it, grind it through a meat grinder, add water 5 times the mass of minced meat of saury, heat and stir at 45°C for 1.5 hours, then add HCl solution (0.5mol / L) to adjust the pH of the system to 4.2, continue to stir and heat for 1.2 hours, centrifuge (5000r / min, 15-20min) to separate, discard the supernatant and the upper layer of grease, and take the precipitate.

[0058] (2) Preparation of uric acid-lowering peptide: add 1.2 times the mass of water to the saury sediment, use 0.5mol / L NaOH solution to adjust the pH of the system to 7.0, raise the temperature of the saury slurry to 53°C, and then add The quality of the saury sediment is 0.6% of Novozymes’ Alcalase 2.4L and 1.0% of Novozymes’s flavor protease, after insulated and hydrolyzed at 53°C for 8 hours, heated at 95°C for 15min, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com