Ferric-carbon complex as well as preparation and application thereof

A composite, iron-carbon technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Use the wet grinding sand mill (model: MiniFer) of Germany Netzsch company laboratory to prepare iron-carbon nanocomposites; (2) grind the zirconia particles (particle size 0.9-1.1mm) Pack into the cavity of the wet grinding sand mill and occupy 80% of the cavity volume; (3) Weigh 4 grams of activated carbon and 36 grams of micron-sized zero-valent iron (below 10 microns in particle size) and 400 mL of propylene glycol in the sand mill. Stir continuously in the feeding tank and mix evenly; (4) Turn on the sand mill and adjust the grinding speed to 3000rpm; (5) Use a peristaltic pump to pump the mixed solution into the chamber of the sand mill for 4 hours of circular grinding; (6) ) Centrifuge the obtained particles from the solution, wash them with ethanol, and dry them in vacuum to obtain the finished iron-carbon composite.

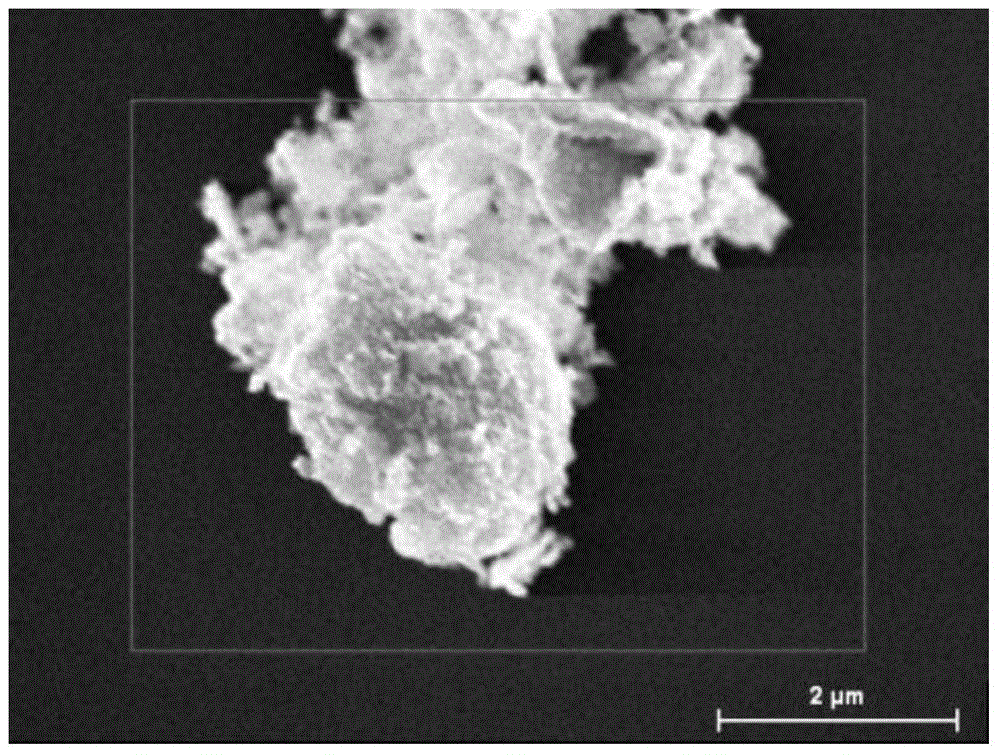

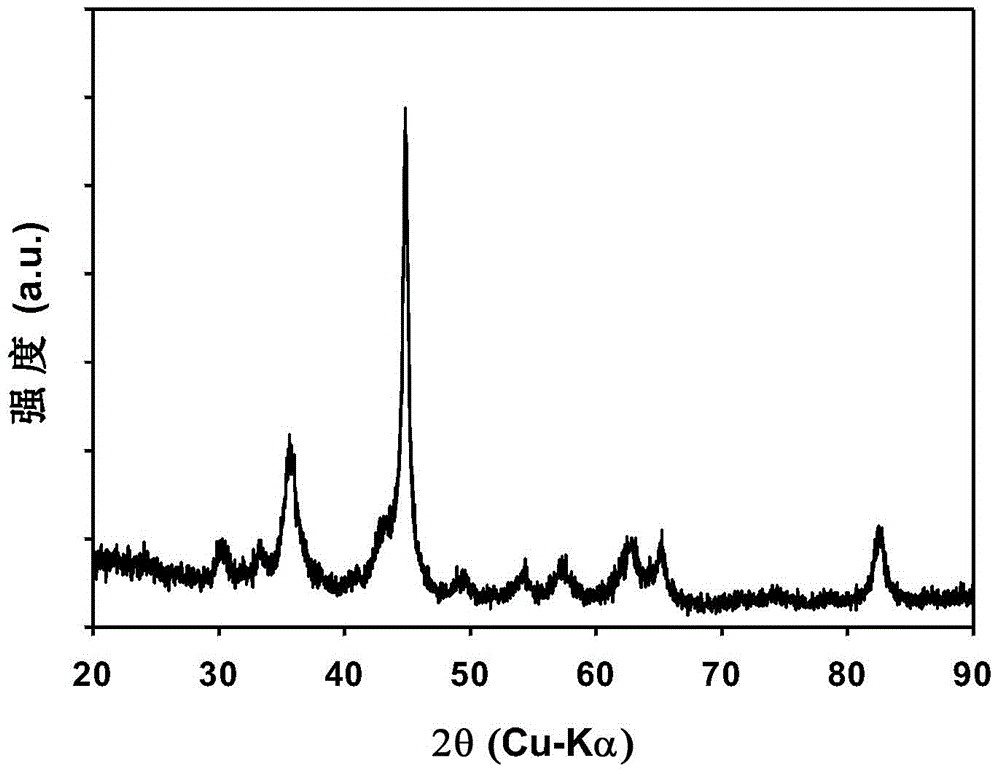

[0033] figure 1 Prepare the scanning electron micrograph of iron-carbon composite body for embodiment 1, figure 1 It can be seen that the i...

Embodiment 2

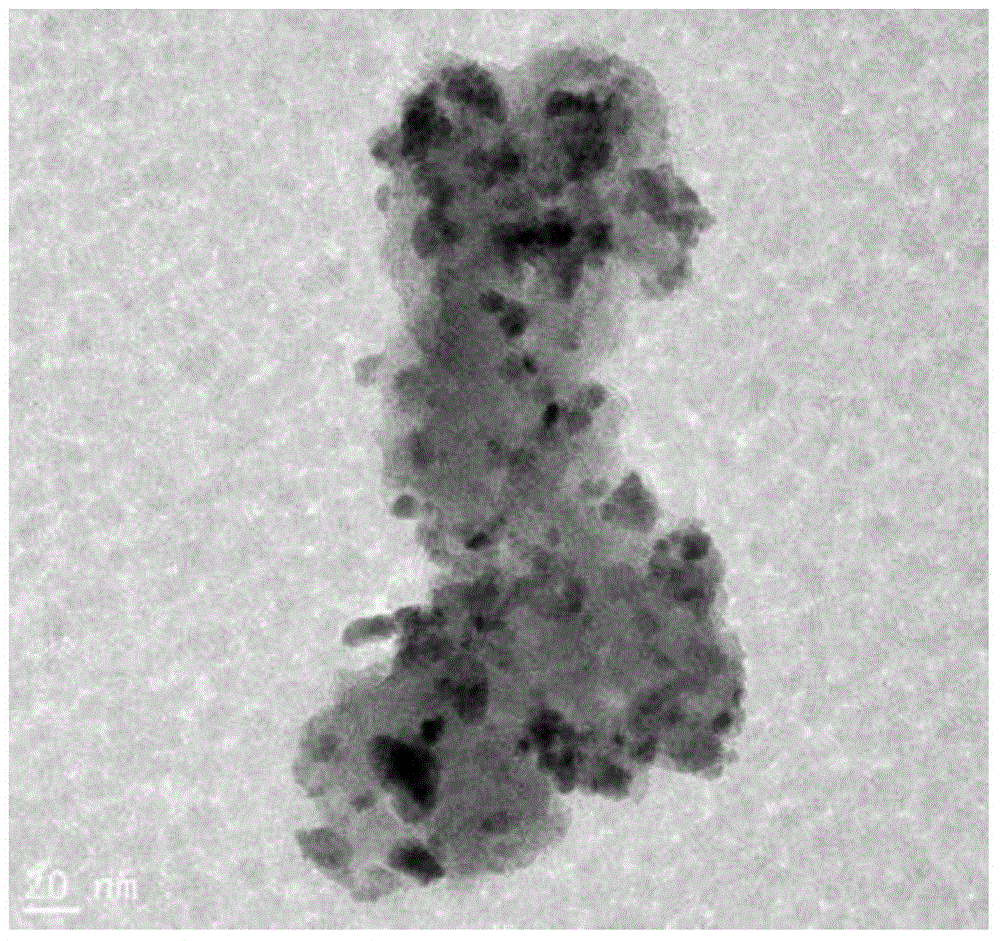

[0041](1) Use the wet grinding sand mill (model: MiniFer) of Germany Netzsch company laboratory to prepare iron-carbon nanocomposites; (2) put the grinding medium iron ball (particle size 0.15mm) into the sand In the mill cavity, 80% of the cavity volume is occupied; (3) Weigh 4 grams of activated carbon and 36 grams of micron-sized zero-valent iron (below 10 microns in particle size) and 400 mL of ethanol in the feeding tank of the sand mill for continuous stirring, Mix evenly; (4) Turn on the sand mill and adjust the grinding speed to 3000rpm; (5) Use a peristaltic pump to pump the mixed solution into the cavity of the sand mill for 4 hours of circular grinding; (6) Grind the mixed solution , set aside to settle to remove the iron balls leaked from the vibrating sieve, pour out the upper mixed solution, centrifuge, wash the solid particles with ethanol, and dry them in vacuum to obtain the finished iron-carbon composite. The TEM and SEM images of the obtained product are sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com