Urban rail vehicle traction system

A vehicle traction and urban rail technology, applied in the field of rail vehicle power, can solve the problem that the vehicle cannot run for a long distance, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

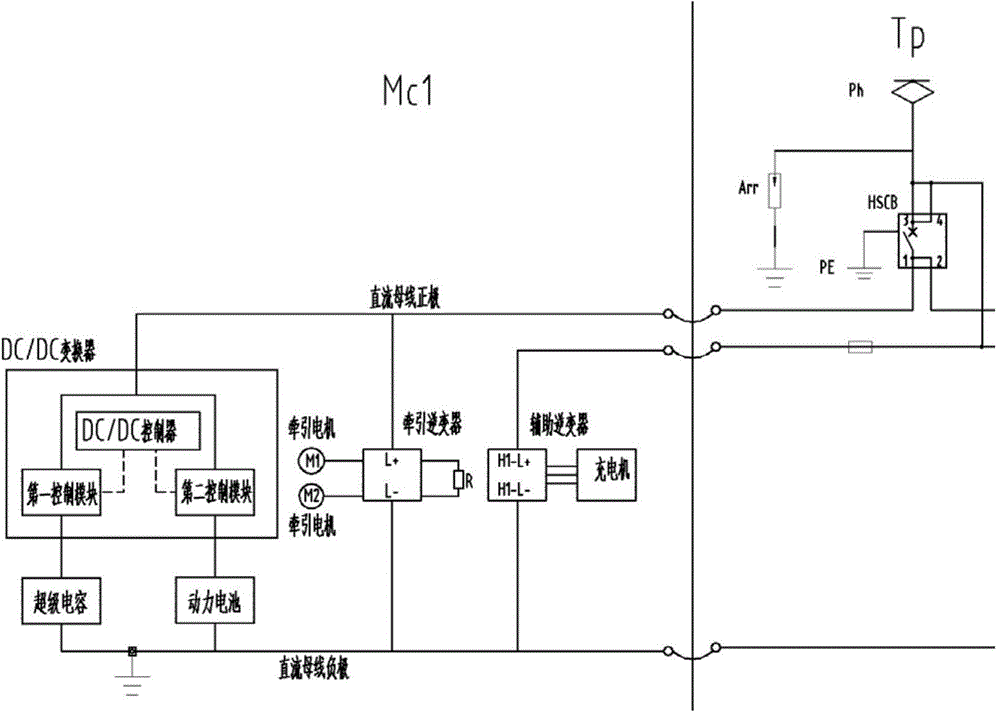

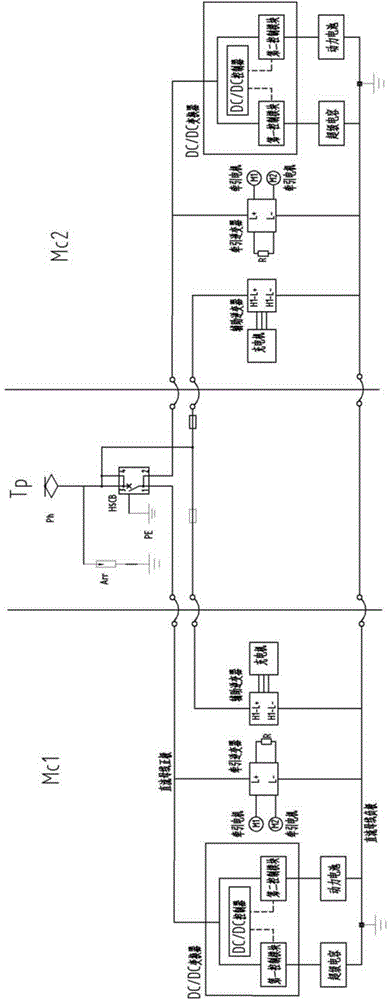

[0021] figure 1 It is a schematic structural diagram of an urban rail vehicle traction system according to an embodiment of the present invention, as figure 1 As shown, MC1 is a motor car with a driver's cab; TP is a trailer with a pantograph; the urban rail vehicle traction system of this embodiment is generally arranged on a motor car, and the traction system includes a power device and an energy storage device; the power device includes a traction Inverter and traction motor. The input terminals of the traction inverter are respectively connected to the positive pole and negative pole of the DC bus of the power supply network. The traction inverter is used for mutual conversion of DC and AC power. The output terminal of the traction inverter is connected to the traction motor. The traction motor is used to power the vehicle and convert kinetic energy into alternating current when the vehicle brakes. The energy storage device includes: a DC / DC converter, a supercapacitor an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com