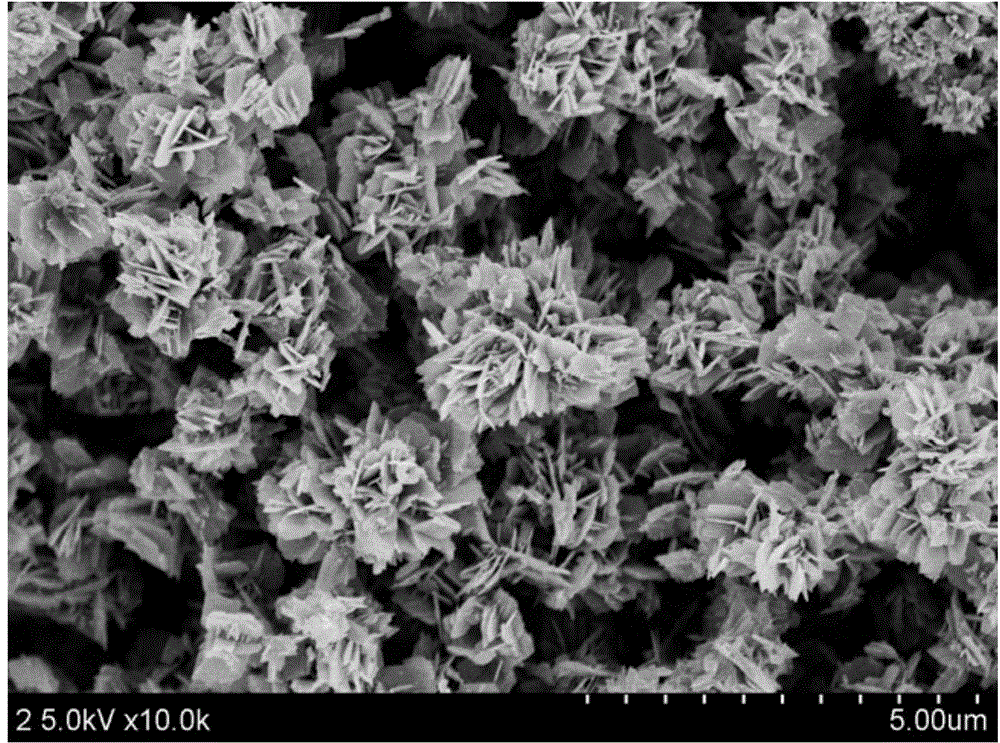

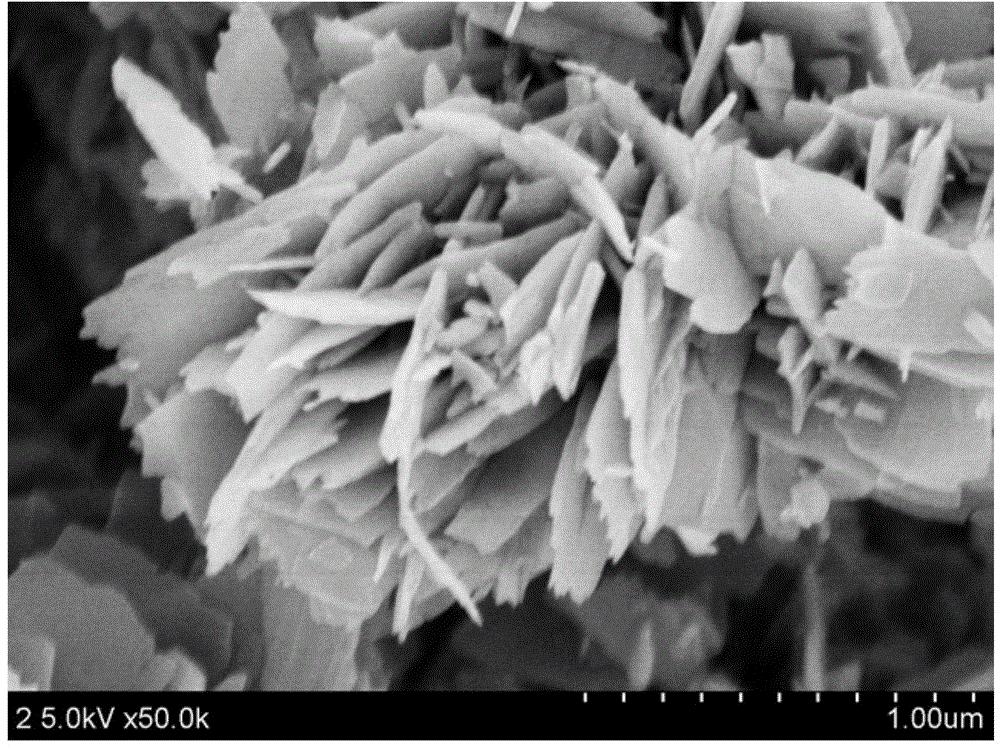

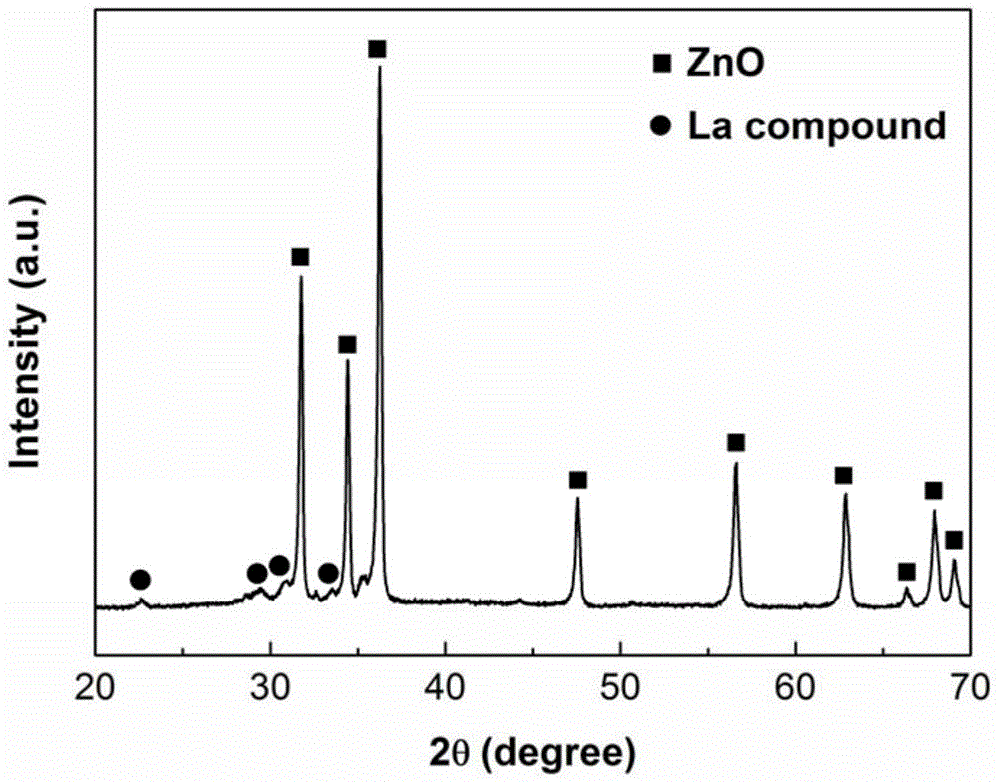

Synthetic method for three-dimensional structure assembled by La surface-modified ZnO nanosheets

A surface modification, three-dimensional structure technology, applied in the field of nanomaterials, can solve the problems of limiting the application and promotion of La-modified ZnO photocatalysts, and achieve the effects of improving the photocatalytic effect, large size and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add a volume of 10 mL of zinc nitrate solution (0.5 mol / L) into a 100 mL beaker, magnetically stir and ice-bath, and another volume of 10 mL of sodium hydroxide solution (3.0 mol / L), put it in a separatory funnel, pass Add the sodium hydroxide solution to the zinc nitrate solution drop by drop using a separatory funnel. Subsequently, 1.0 mL of sodium lauryl sulfate solution (0.2 mol / L) and a certain volume of distilled water were added to obtain a mixed solution with a volume of 50 mL. Remove the ice bath, continue to stir vigorously at room temperature for 1.5 h, and stand still to obtain a precursor solution. The precursor solution was transferred to an Erlenmeyer flask with a ground glass stopper, and the Erlenmeyer flask was placed in a constant temperature water bath for 5 hours at 70°C to obtain a white precipitate. The white precipitate was separated by suction filtration, washed with distilled water and ethanol, and dried in a constant temperature blast drying ...

Embodiment 2

[0033]Add 10 mL of zinc nitrate solution (1.0 mol / L) into a 100 mL beaker, stir magnetically and in an ice bath, and take another 10 mL of sodium hydroxide solution (4.0 mol / L), put it in a separatory funnel, and pass Add the sodium hydroxide solution to the zinc nitrate solution drop by drop using a separatory funnel. Then 2.5 mL of sodium dodecyl sulfate solution (0.2 mol / L) and a certain volume of distilled water were added to obtain a mixed solution with a volume of 50 mL. Remove the ice bath, continue to stir vigorously at room temperature for 1.5 h, and stand still to obtain a precursor solution. The precursor solution was transferred to an Erlenmeyer flask with a ground glass stopper, and the Erlenmeyer flask was placed in a constant temperature water bath for 5 hours at 80°C to obtain a white precipitate. The white precipitate was separated by suction filtration, washed with distilled water and ethanol, and dried in a 70°C constant temperature blast drying oven. Afte...

Embodiment 3

[0035] Add 10 mL of zinc nitrate solution (1.5 mol / L) into a 100 mL beaker, stir magnetically and in an ice bath, and take another 10 mL of sodium hydroxide solution (5.0 mol / L), put it in a separatory funnel, and pass Add the sodium hydroxide solution to the zinc nitrate solution drop by drop using a separatory funnel. Subsequently, 5.0 mL of sodium lauryl sulfate solution (0.2 mol / L) and a certain volume of distilled water were added to obtain a mixed solution with a volume of 50 mL. Remove the ice bath, continue to stir vigorously at room temperature for 1.5 h, and stand still to obtain a precursor solution. The precursor solution was transferred to an Erlenmeyer flask with a ground glass stopper, and the Erlenmeyer flask was placed in a constant temperature water bath for 5 hours at 85°C to obtain a white precipitate. The white precipitate was separated by suction filtration, washed with distilled water and ethanol, and dried in a constant temperature blast drying oven at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com