Single-coated UV light cured color effect paint applied to plastic substrates and preparation

An ultraviolet and light curing technology, applied in coatings, polyester coatings, polyether coatings, etc., can solve the problems of insufficient photoinitiator activity, non-dry coating film, incomplete polymerization reaction of photocurable resin and reactive diluent, etc. , to achieve the effect of small molecular weight, tight network coating structure, improved wear resistance and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method for a single-coated UV ultraviolet photocuring color effect paint applied to a plastic base material, the method comprising the following steps:

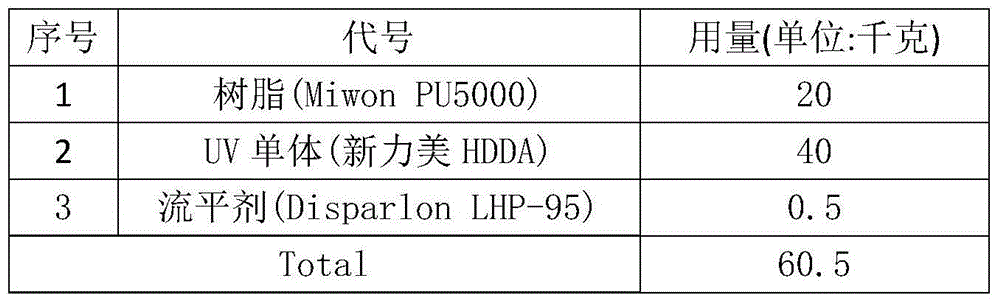

[0041] (1) Preparation of mixture A:

[0042]

[0043] (i) Add the resin, UV monomer, and leveling agent into the small bucket first according to the formula requirements, and stir at 800-900 rpm, stir for 5-10 minutes, and keep the temperature at 30-50°C;

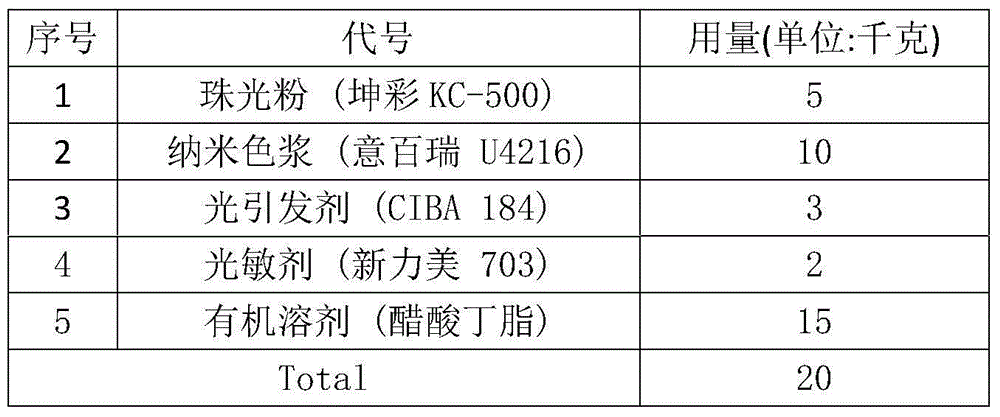

[0044] (2) Preparation of mixture B:

[0045]

[0046] (ii) Add pearlescent pigment, nano-color paste, photoinitiator, and photosensitizer into the large tank according to the formula requirements, stir at 800-1200 rpm for 5-10 minutes, and keep the temperature at 30-50°C;

[0047] (iii) The mixture obtained in the sampling step (ii) is tested for cleanliness, and the scraper paper is scraped with a 100um wet film preparation device, and there are no obvious particles on the scraper paper;

[0048] (iv) Add the mixture obtained in step (i) int...

Embodiment 2

[0052] (1) Preparation of mixture A:

[0053]

[0054] (i) Add the resin, UV monomer, and leveling agent into the small bucket first according to the formula requirements, and stir at 800-900 rpm for 5-10 minutes, keeping the temperature at 30-50°C;

[0055] (2) Preparation of mixture B:

[0056]

[0057] (ii) Add pearlescent pigments, colorants, photoinitiators, and photosensitizers into the vat according to the recipe requirements, stir at 800-1200 rpm for 5-10 minutes, and keep the temperature at 30-50°C;

[0058] (iii) Sampling (ii) To test the cleanliness, use a 100um wet film preparer to scrape on the scraper paper, and there are no obvious particles on the scraper paper;

[0059] (iv) Add (i) into (ii), stir at 800-900 rpm for 5-10 minutes;

[0060] (v) Sampling (iv) Check the cleanliness. After there are no obvious particles, use the Iwata #2 cup to check and adjust to the range of 9 to 10 seconds;

[0061] (vi) filter, weigh and pack.

Embodiment 3

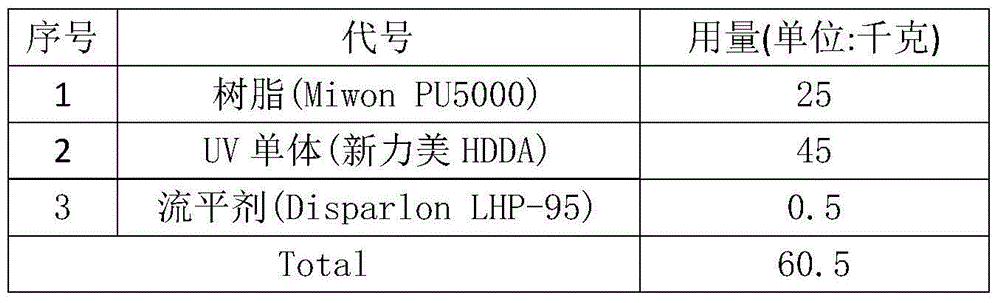

[0063] (1) Preparation of mixture A:

[0064]

[0065] (i) Add the resin, UV monomer, and leveling agent into the small bucket first according to the formula requirements, and stir at 800-900 rpm for 5-10 minutes, keeping the temperature at 30-50°C;

[0066] (2) Preparation of mixture B:

[0067]

[0068] (ii) Add pearlescent pigments, colorants, photoinitiators, and photosensitizers into the vat according to the recipe requirements, stir at 800-1200 rpm for 5-10 minutes, and keep the temperature at 30-50°C;

[0069] (iii) Sampling (ii) To test the cleanliness, use a 100um wet film preparer to scrape on the scraper paper, and there are no obvious particles on the scraper paper;

[0070] (iv) Add (i) into (ii), stir at 800-900 rpm for 5-10 minutes;

[0071] (v) Sampling (iv) Check the cleanliness. After there are no obvious particles, use the Iwata #2 cup to check and adjust to the range of 9 to 10 seconds;

[0072] (vi) filter, weigh and pack.

[0073] When using thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com