Electrophoretic color filling process

A process and color-filling technology, applied in the field of electrophoretic color-filling process, can solve the problems of poor electrophoretic layer adhesion between the electrophoretic layer and the etched bottom layer, and achieve the effect of solving the poor performance of the electrophoretic layer and solving the adhesion problem.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

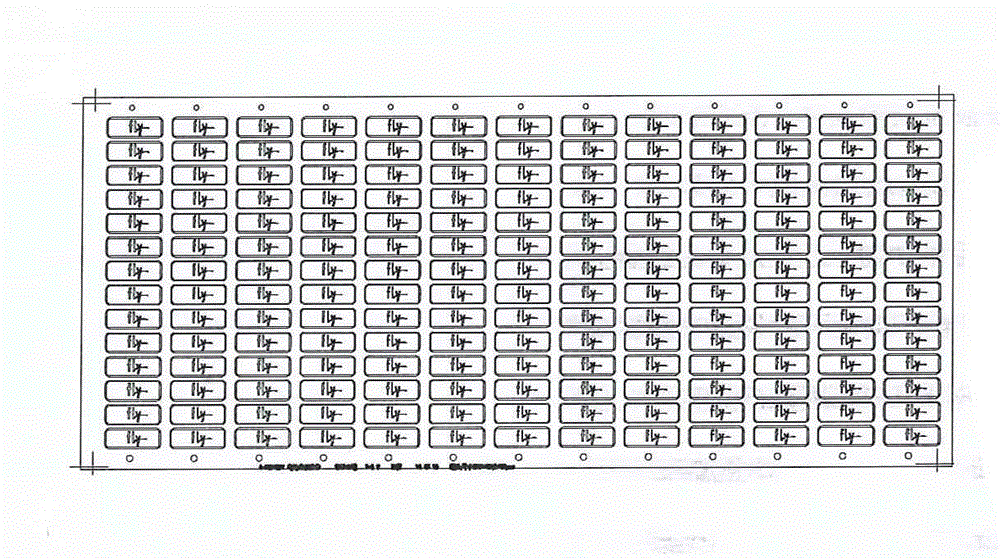

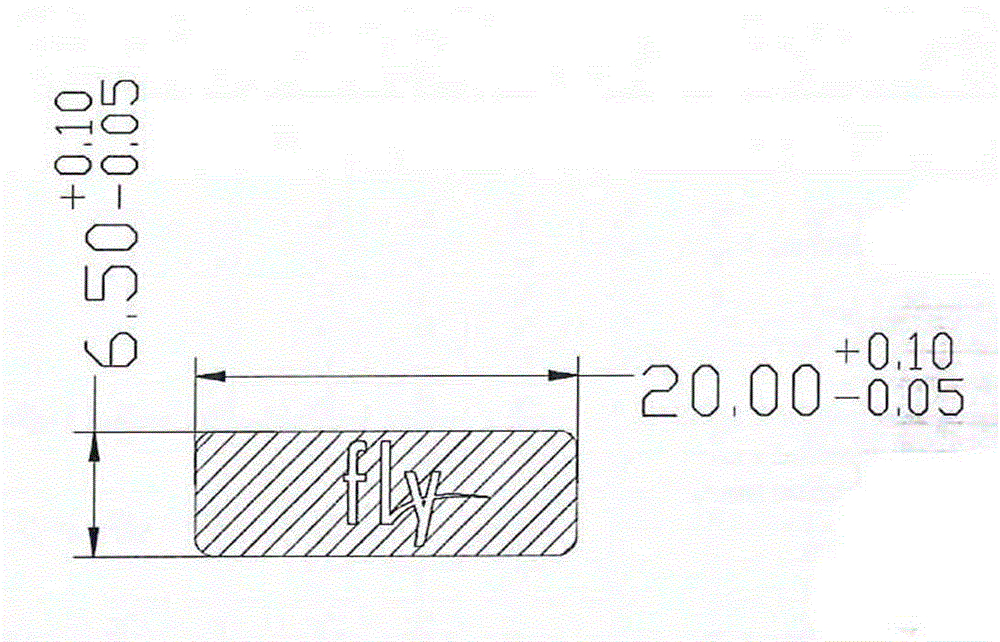

[0053] figure 1 It is a schematic diagram of the structural dimensions of a mobile phone decoration made of stainless steel sheet with a thickness of 0.3mm. The length is 20.00mm, and the tolerances are +0.1mm and -0.05mm respectively; the width is 6.50mm, and the tolerances are +0.1mm and -0.05mm respectively. mm; the three English letters FLY in the middle have a stainless steel mirror effect, which cannot be produced by traditional etching and manual oil filling, because the font is too small and the black area is too large, and it is easy to damage the black matte area when oiling after oiling, so only using Technology of the present invention just can be finished, and concrete steps are as follows:

[0054] step 1:

[0055] Pre-processing of metal products: This step is the pre-processing process of the product. Because it is a flat sig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap