Growth device, growth furnace and preparation method of yttrium lithium fluoride laser crystals

A technology of yttrium lithium fluoride and growth device, which is applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of destroying the crystal growth process, difficulty in salvaging floating objects, unstable solid-liquid interface, etc., and achieves high repeatability The effect of stability and stability, the shape of solid-liquid interface is easy to maintain stability, and the control is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

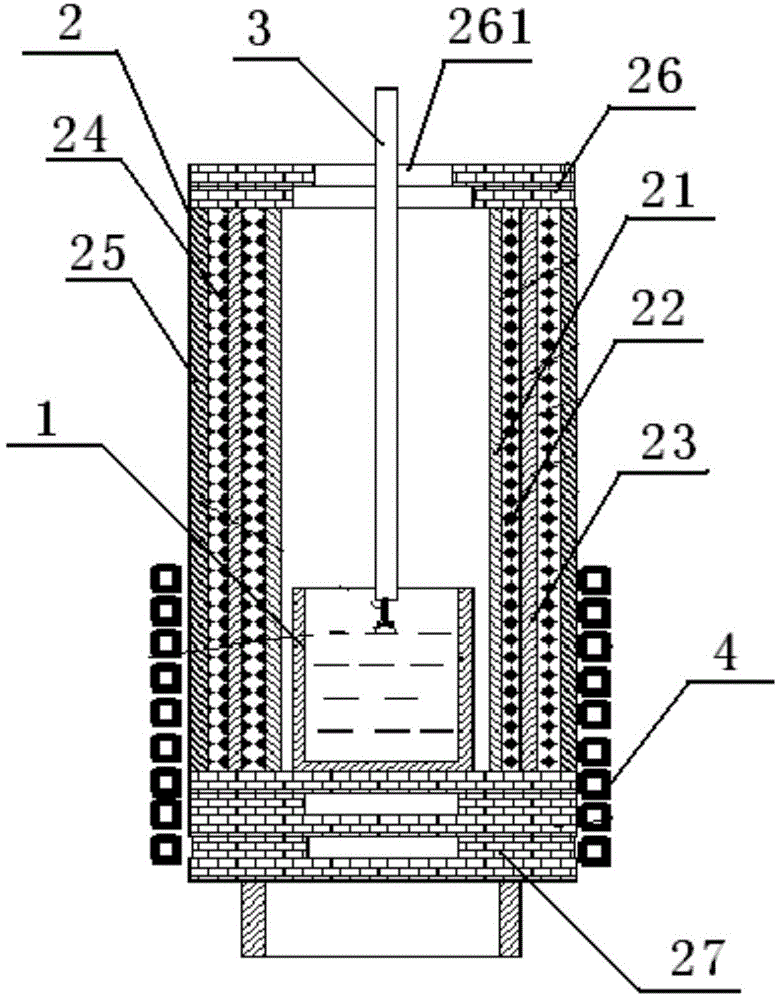

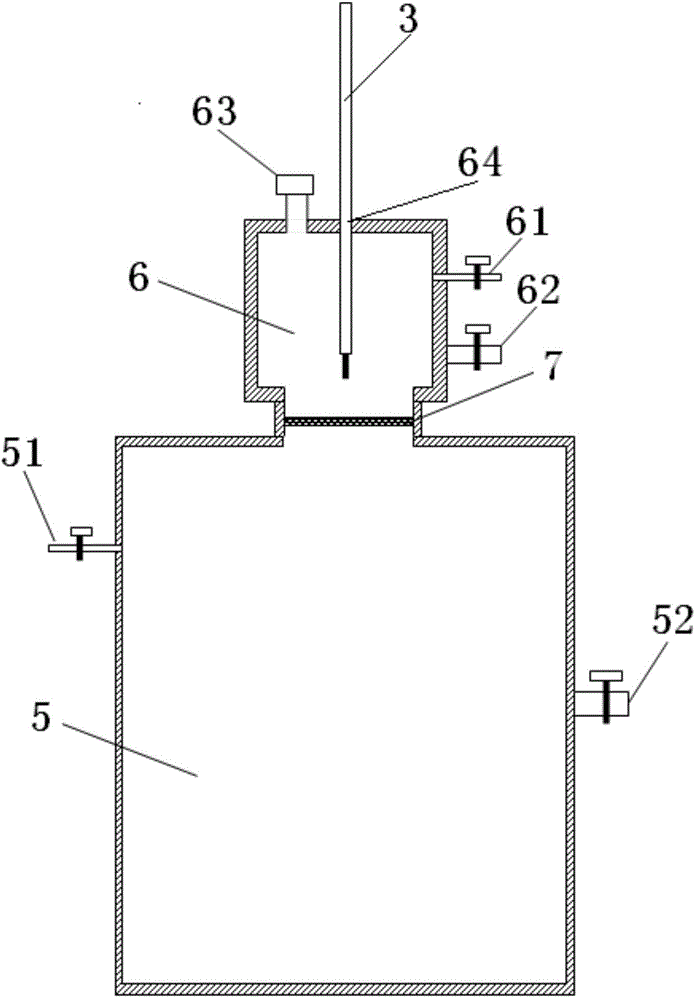

[0132] This embodiment adopts the provided by the present invention figure 1 The crystal growth device of the shown structure and figure 2 The crystal growth furnace with the structure shown is used to prepare Nd:YLF crystals. Among them, the Φ150×200mm platinum crucible is used to hold the melt; the insulation cylinder is made of 5 layers of insulation cylinders: the first layer of insulation cylinder is made of carbon doped with 10wt%, density ≥ 1.8g / cm 3 , boron nitride (BN) ceramics with a thickness of 10mm; the second layer of insulation cylinder is graphite felt with a thickness of 10mm; the third layer of insulation cylinder is made of carbon-doped 10wt%, density ≥ 1.2g / cm 3 , BN ceramics with a thickness of 10mm; the fourth layer of insulation cylinder is graphite felt with a thickness of 5mm; the fifth layer of insulation cylinder is carbon-doped 0wt%, density ≥ 1.8g / cm 3 , BN ceramics with a thickness of 5mm. The insulating disc at the bottom is composed of 5 lay...

Embodiment 2

[0139] This embodiment adopts the provided by the present invention figure 1 The crystal growth device of the shown structure and figure 2 The crystal growth furnace with the structure shown was used to prepare Ho:YLF crystals. Among them, the Φ120×120mm platinum crucible is used to hold the melt; the insulation cylinder is made of 5 layers of insulation cylinders: the first layer of insulation cylinder is made of carbon doped with 5wt%, density ≥ 1.8g / cm 3 , boron nitride (BN) ceramics with a thickness of 5mm; the second layer of insulation cylinder is graphite felt with a thickness of 10mm; the third layer of insulation cylinder is made of carbon-doped 2wt%, density ≥ 1.2g / cm 3 , BN ceramics with a thickness of 10mm; the fourth layer of insulation cylinder is graphite felt with a thickness of 5mm; the fifth layer of insulation cylinder is carbon-doped 0wt%, density ≥ 1.8g / cm 3 , BN ceramics with a thickness of 5mm. The insulating disc at the bottom is composed of 5 layer...

Embodiment 3

[0146] This embodiment adopts the provided by the present invention figure 1 The crystal growth device of the shown structure and figure 2 A crystal growth furnace with the structure shown was used to prepare Tm:YLF crystals. Among them, the Φ120×180mm platinum crucible is used to hold the melt; the insulation cylinder is made of 5 layers of insulation cylinders: the first layer of insulation cylinder is made of carbon-doped 0wt%, density ≥ 1.8g / cm 3 , boron nitride (BN) ceramics with a thickness of 10mm; the second layer of insulation cylinder is graphite felt with a thickness of 10mm; the third layer of insulation cylinder is made of carbon-doped 10wt%, density ≥ 1.2g / cm 3 , BN ceramics with a thickness of 10mm; the fourth layer of insulation cylinder is graphite felt with a thickness of 5mm; the fifth layer of insulation cylinder is carbon doped with 5wt%, density ≥ 1.8g / cm 3 , BN ceramics with a thickness of 5mm. The insulating disc at the bottom is composed of 5 layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com