Vacuum pulsation ultrasonic drying equipment

A drying equipment, vacuum ultrasonic technology, applied in the direction of drying solid materials, local agitation dryer, lighting and heating equipment, etc., can solve the problems of low production efficiency, reduced activity, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

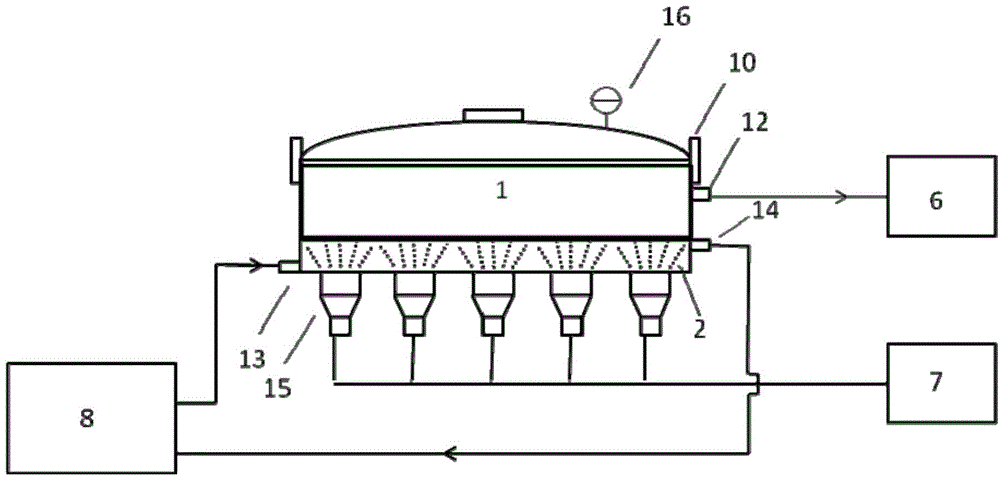

[0094] A vacuum ultrasonic drying equipment, such as figure 1 As shown, it includes the following structures: drying chamber 1, cooling jacket layer 2, vacuum control system 6, ultrasonic control system 7, circulation refrigeration control system 8, quick opening valve 10, air suction port 12, circulation refrigeration liquid inlet 13, circulation refrigeration Liquid outlet 14, several ultrasonic transducers 15, vacuum gauge 16; The ultrasonic transducer 15 is at the bottom of the cooling jacket layer 2, and the ultrasonic energy is transmitted to the drying chamber 1 through the cooling jacket layer 2; several ultrasonic transducers The transducers 15 are all controlled by the ultrasonic control system 7; the vacuum control system 6 extracts the gas in the drying chamber 1 through the suction port 12 located on the side of the drying chamber; the circulating refrigerant in the cooling jacket layer 2 is provided by the circulating freezing control system 8 The circulating ref...

Embodiment 2

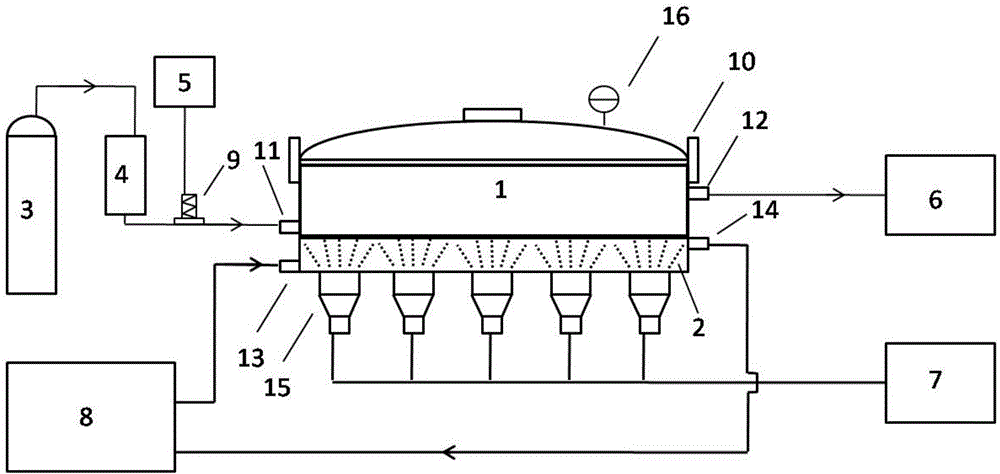

[0096] A vacuum pulsation ultrasonic drying equipment, such as figure 2As shown, it includes the following structures: drying chamber 1, cooling jacket layer 2, air supply system 3, dry filter 4, switch control system 5, vacuum control system 6, ultrasonic control system 7, cycle refrigeration control system 8, valve 9 , quick opening valve 10, air inlet 11, air extraction port 12, circulating refrigerant inlet 13, circulating refrigerant outlet 14, several ultrasonic transducers 15, vacuum gauge 16; the several ultrasonic transducers 15 are uniform Distributed at the bottom of the cooling jacket layer 2, the ultrasonic energy is transmitted to the drying chamber 1 through the cooling jacket layer 2; the several ultrasonic transducers 15 are controlled by the ultrasonic control system 7; the vacuum control system 6 is located on the side of the drying chamber The gas extraction port 12 of the air extraction port 1 extracts the gas in the drying chamber 1; the circulating refr...

Embodiment 3

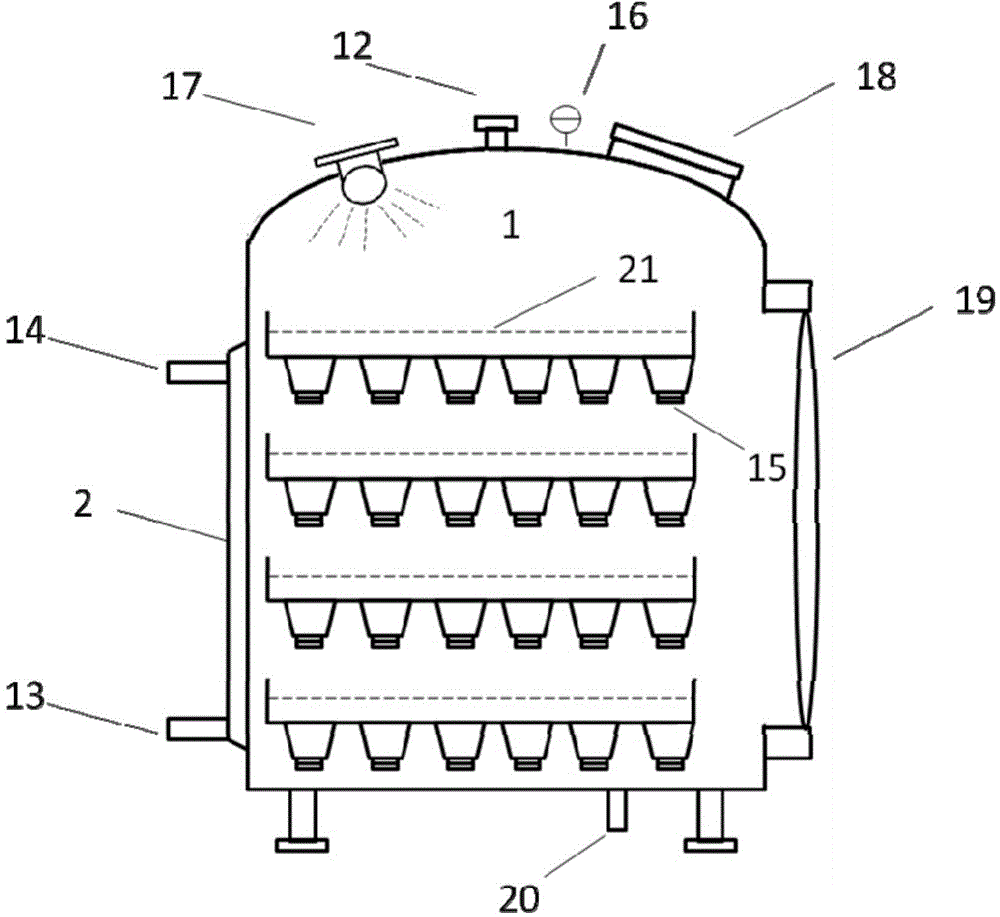

[0098] A multi-layer vacuum ultrasonic drying equipment, such as image 3 As shown, it includes the following structures: drying chamber 1, cooling jacket layer 2, vacuum control system, ultrasonic control system, cyclic refrigeration control system, air extraction port 12, circulating refrigerating liquid inlet 13, circulating refrigerating liquid outlet 14, ultrasonic transducer 15. Vacuum gauge 16, lighting equipment 17, viewing window 18, side door 19, sewage outlet 20 and material tank 21; material tank 21 is distributed in multiple layers in the drying chamber; cooling jacket layer 2 surrounds the drying chamber; sewage outlet 20 is located The bottom of the drying chamber 1; the bottom of each material tank 21 is uniformly provided with several (at least one) ultrasonic transducers 15, and the material tank 21 and the ultrasonic transducer 15 are controlled by the ultrasonic control system; 12 Extract the gas in the drying chamber 1; the circulating refrigerating liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com