A pretreatment method for observing titanium fiber metallographic structure sintering neck

A technology of metallographic structure and titanium fiber is applied in the field of pretreatment for observing the metallographic structure of titanium fiber sintered neck, which can solve the problem that the corrosion solution and the observation method cannot clearly and completely observe the metallographic structure of titanium fiber porous materials, and achieve Clear grain boundaries and good corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for observing the sintering neck of the titanium fiber porous material metallographic structure. The method specifically includes the following steps:

[0033] Step 1, sample cleaning:

[0034] After the titanium fiber porous material (square size 24mm × 24mm × 31mm) is obtained, the wire diameter is 70-120um, and the porosity is 40%-60%. Wash for 3 to 5 minutes, then rinse with water for 3 minutes, rinse off the HCl solution, then wash the sample with pure hydrofluoric acid solution for 5 to 8 minutes, and then rinse with water for 2 to 4 minutes, rinse off the hydrofluoric acid solution, the solution If the concentration is high, pay attention to splashing and keep the fume hood ventilated; then place a measuring cup in an ultrasonic cleaner, add 100ml of absolute ethanol to the measuring cup, soak and clean the sample in absolute ethanol for 20 minutes, and then take out the sample. Air-dried at low temperature and sealed for storag...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is:

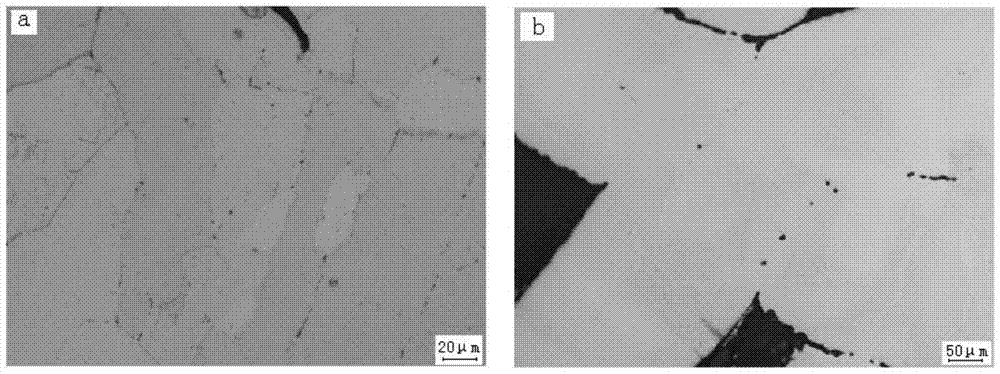

[0049] The components of the metallographic etching solution for titanium fiber porous materials include analytically pure hydrofluoric acid, analytically pure nitric acid, and hydrochloric acid with a mass fraction of 35%. In the etching solution, HF: HNO3: 35% HCl=4ml: 2ml: 10ml are used respectively ( image 3 a) and HF:HNO 3 : 35% HCl=4ml: 2ml: 4ml ( image 3 b).

[0050] Take the sample after the secondary corrosion, observe the metallographic sintering neck of the titanium fiber porous material under a microscope, and observe the sintering effect of the sample: as image 3 As shown in a, observe the metallographic structure and find that the metallographic structure is blurred; as image 3 As shown in b, observing the metallographic structure, the metallographic structure at the sintered node of the titanium fiber porous material can be clearly observed.

Embodiment 3

[0052] The difference between this embodiment and embodiment 1 is that

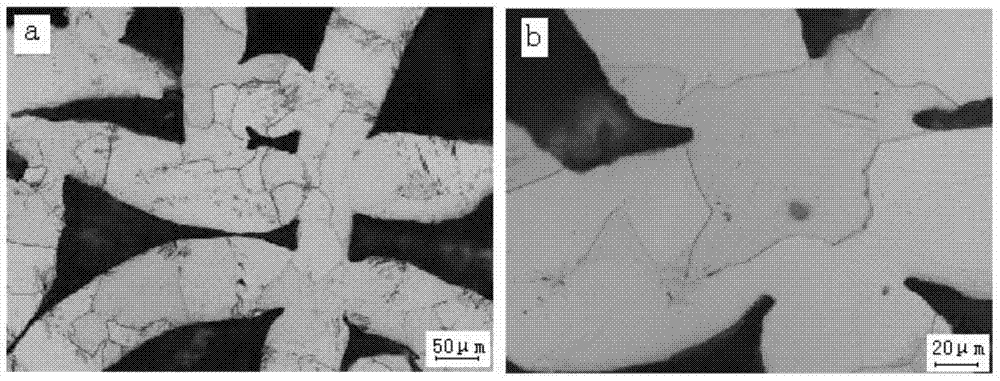

[0053] Step 4, prepare metallographic etching solution: uniformly mix and prepare metallographic etching solution for titanium fiber porous material according to the following formula: the components of metallographic etching solution for titanium fiber porous material include analytically pure hydrofluoric acid, analytically pure nitric acid, and the mass fraction is 35 % hydrochloric acid, in the corrosion solution, use HF respectively: HNO3: 35% HCl=10ml: 1ml: 2ml ( Figure 4 a), HF: HNO3: 35% HCl=1ml: 8ml: 4ml ( Figure 4 b) and HF: HNO3: 35% HCl=4ml: 2ml: 4ml ( Figure 4 c).

[0054] Observe the metallographic sintering neck of the titanium fiber porous material under the microscope, and observe the sintering effect of the sample: as Figure 4 As shown in a and 4b, observe the metallographic structure and find that the metallographic structure is blurred; Figure 4 As shown in c, observing the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com