Fancy reflective cloth and preparation method thereof

A reflective cloth and fancy technology, which is applied in the direction of chemical instruments and methods, optics, optical components, etc., can solve the problems of single style, lack of breathability, sweat absorption, single color, etc., and achieve the effect of novel style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

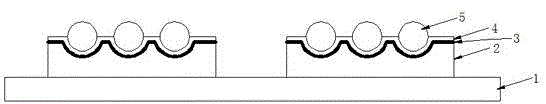

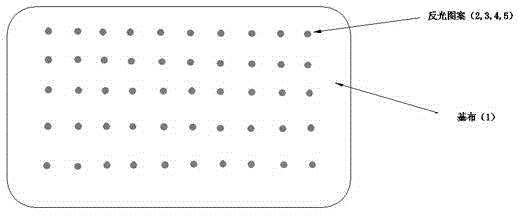

[0079] Such as figure 1 and figure 2 The air-permeable fancy reflective fabric includes a base fabric 1, a composite adhesive layer 2, a coating layer 3, a focusing layer 4, and a glass bead layer 5, and the composite adhesive layer 2 is provided on the part of the base fabric 1, The composite adhesive layer 2 is provided with a coating 3, the coating 3 is provided with a focusing layer 4, the focusing layer 4 is provided with a glass bead layer 5, and the fancy pattern of the composite adhesive layer is is a dot; the coating is selected from metal aluminum coating, metal titanium coating, metal silver coating, zinc sulfide transparent coating, cryolite transparent coating, silicon monoxide transparent coating, silicon oxide transparent coating, indium oxide transparent coating, nitride The first or more of the titanium translucent coatings; the base cloth is selected from chemical fiber cloth, TC cloth, stretch cloth, Oxford cloth, pure cotton cloth, PU leather, PVC leather...

Embodiment 2

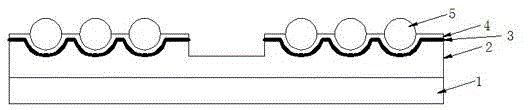

[0081] Such as image 3 and Figure 4 The non-breathable fancy reflective fabric includes a base cloth 1, a composite adhesive layer 2, a coating layer 3, a focusing layer 4, and a glass bead layer 5. The base cloth 1 is provided with a composite adhesive layer 2, Part of the composite adhesive layer 2 is provided with a coating 3, the coating 3 is provided with a focusing layer 4, and the focusing layer 4 is provided with a glass bead layer. The fancy pattern of the composite adhesive layer is a dot; the coating is selected from metal aluminum coating, metal titanium coating, metal silver coating, zinc sulfide transparent coating, cryolite transparent coating, silicon monoxide transparent coating, silicon oxide transparent coating, indium oxide transparent coating, nitride The first or more of the titanium translucent coatings; the base cloth is selected from chemical fiber cloth, TC cloth, stretch cloth, Oxford cloth, pure cotton cloth, PU leather, PVC leather, bird's eye c...

Embodiment 3

[0083] Preparation method of breathable fancy reflective cloth:

[0084] (1) Implantation of glass beads: place the PE / PET composite film on a hot roller, the temperature is controlled between 140-200°C, as the PE film melts, the glass beads settle on the PE film, and the PE film After cooling, the glass beads are fixed on the PE / PET composite film to realize bead planting;

[0085] (2) Focusing layer: apply paint on the surface of the glass microspheres to form a focusing layer concentric with the glass beads, and dry the solvent at about 100°C to form a film. This film is called a plant film, and the focusing layer The thickness is 0.1μm;

[0086] (3) Metal silver coating: through resistance heating, the metal silver coating medium changes from solid to gaseous state, and sublimates into a coating after meeting the bead planting film, which is a composite reflective layer, and the thickness of the silver coating is 0.1nm;

[0087] (4) Fancy roller-coated compound glue: ado...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com