Active modified milk and preparation method thereof

A technology for modulating milk and activeness, applied in dairy products, milk preparations, applications, etc., can solve the problems of short shelf life, easy to destroy active ingredients, high heating intensity of UHT sterilized milk, etc., and achieve the effect of good taste and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

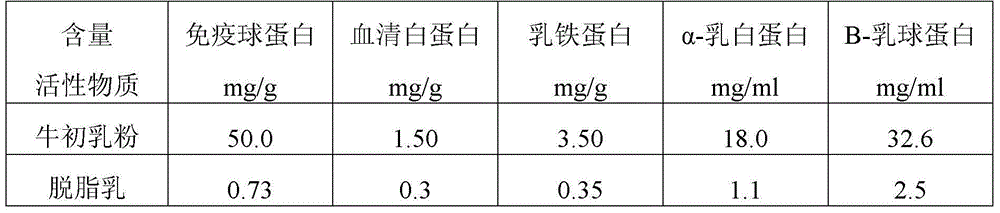

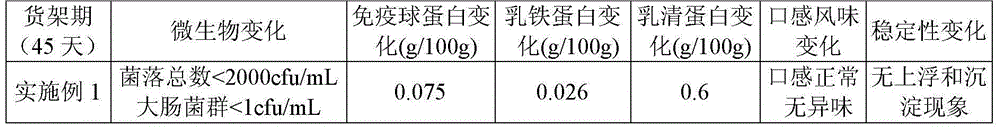

[0077] Embodiment 1: Modulated milk containing bovine colostrum powder

[0078] Formula: (per 100g of product) 78g of ordinary fresh milk (excluding reconstituted milk), 0.5g of bovine colostrum powder, 0.1g of soybean lecithin, 0.0012g of vitamin E (natural), and the balance is sterile purified water.

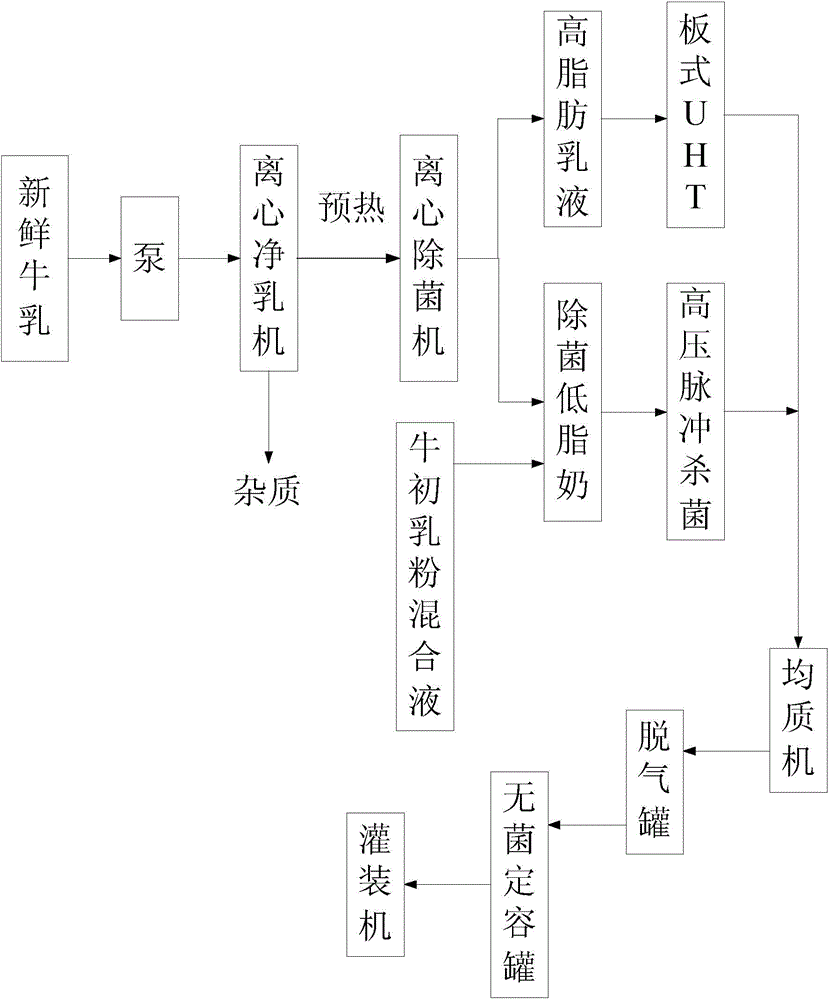

[0079] preparation process (such as figure 1 shown):

[0080] (1) Centrifugation: Pass qualified fresh raw milk (10°C) through a centrifugal milk cleaning machine (rotating speed 6500rpm) to remove larger particle impurities; preheat the obtained clean milk to 50°C and enter a high-speed centrifugal sterilizer (rotating speed 7500rpm ), remove the spores to obtain sterilized low-fat milk and separated high-fat emulsion.

[0081] (2) Mixing: Sterilize the separated high-fat emulsion at a temperature of 140°C / 4s; dissolve bovine colostrum powder, soybean lecithin, and Ve in 15 grams (50°C) of sterile water, and add the solution to the above In sterilized skim milk.

[0082] ...

Embodiment 2

[0091] Embodiment 2: Modulated milk containing bovine colostrum powder

[0092] Formula: (per 100g of product) 75g of ordinary fresh milk (excluding reconstituted milk), 1.0g of bovine colostrum powder, 0.15g of soybean lecithin, 0.003g of vitamin E (natural), and the balance is sterile purified water.

[0093] (1) Centrifugation: Pass qualified fresh raw milk (10°C) through a centrifugal milk cleaning machine (rotating speed 7500rpm) to remove larger particles of impurities; preheat the obtained clean milk to 55°C and enter a high-speed centrifugal sterilizer (rotating speed 8000rpm ), remove the spores to obtain sterilized low-fat milk and separated high-fat emulsion.

[0094] (2) Mixing: Sterilize the separated high-fat emulsion at a temperature of 140°C / 4s; dissolve bovine colostrum powder, soybean lecithin, and Ve in 15 grams (45°C) of sterile water, and add the solution to the above In sterilized skim milk.

[0095] (3) High-pressure pulse sterilization: pass the above...

Embodiment 3

[0104] Embodiment 3: Contain the modulation milk of bovine colostrum powder

[0105] Formula: (per 100g of product) 75g of ordinary fresh milk (excluding reconstituted milk), 1.5g of bovine colostrum powder, 0.2g of soybean lecithin, 0.005g of vitamin E (natural), and the balance is sterile purified water.

[0106] making process:

[0107] (1) Centrifugation: Pass qualified fresh raw milk (10°C) through a centrifugal milk cleaning machine (rotating speed 6800rpm) to remove larger particles of impurities; preheat the obtained clean milk to 53°C and enter a high-speed centrifugal sterilizer (rotating speed 7800rpm ), remove the spores to obtain sterilized low-fat milk and separated high-fat emulsion.

[0108] (2) Mixing: Sterilize the separated high-fat emulsion at a temperature of 140°C / 4s; dissolve bovine colostrum powder, soybean lecithin, and Ve in 15 grams (48°C) of sterile water, and add the solution to the above In sterilized skim milk.

[0109] (3) High-pressure pulse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com