Preparation method of nano vitamin D3 for coating of feed

A vitamin and nanotechnology, applied in animal feed, animal feed, application, etc., can solve the problem of D3 biological activity reduction, achieve the effects of reducing resource waste, improving bioavailability, and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the present invention is a kind of nano-vitamin D3 that is used for feed production, and the nutrient content in every 1 kilogram of nano-vitamin D3 powders is: Vitamin D3 500,000 international units (IU) / gram (g), surplus is carrier . Its preparation method comprises the following steps:

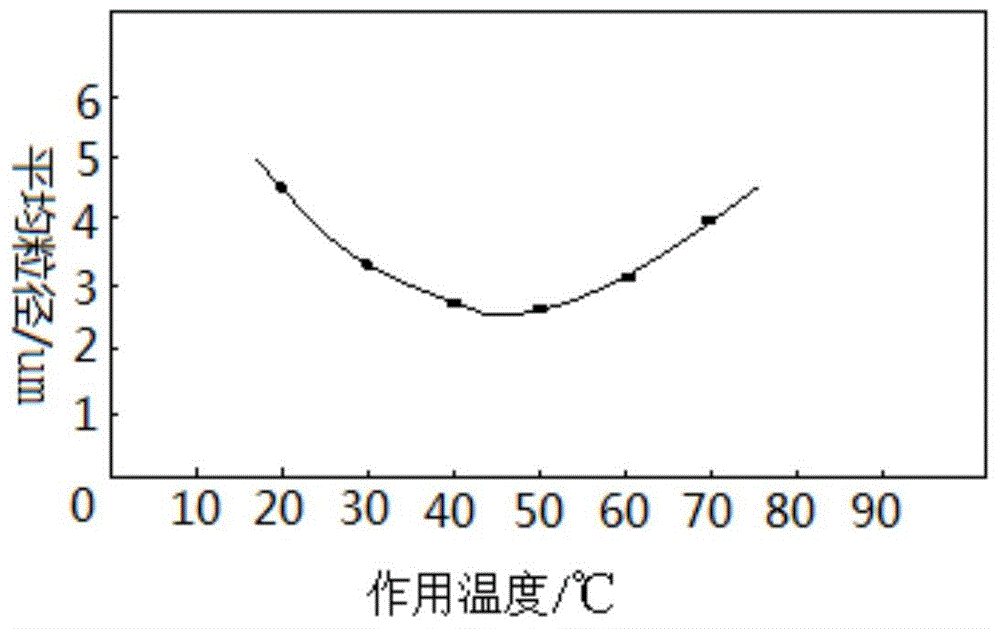

[0031] 1) Weigh 100g of vitamin D3 raw material, and mix it according to the mass ratio of vitamin D3 raw material:VD3 oil at 1:1 under the preheating condition of 45°C;

[0032] 2) Keep preheating at 45°C, and perform ultrasonic emulsification on the mixture of vitamin D3 raw materials and VD3 oil for 8-12 minutes, so that the average particle size of the obtained nanoemulsion emulsion is 3-5um;

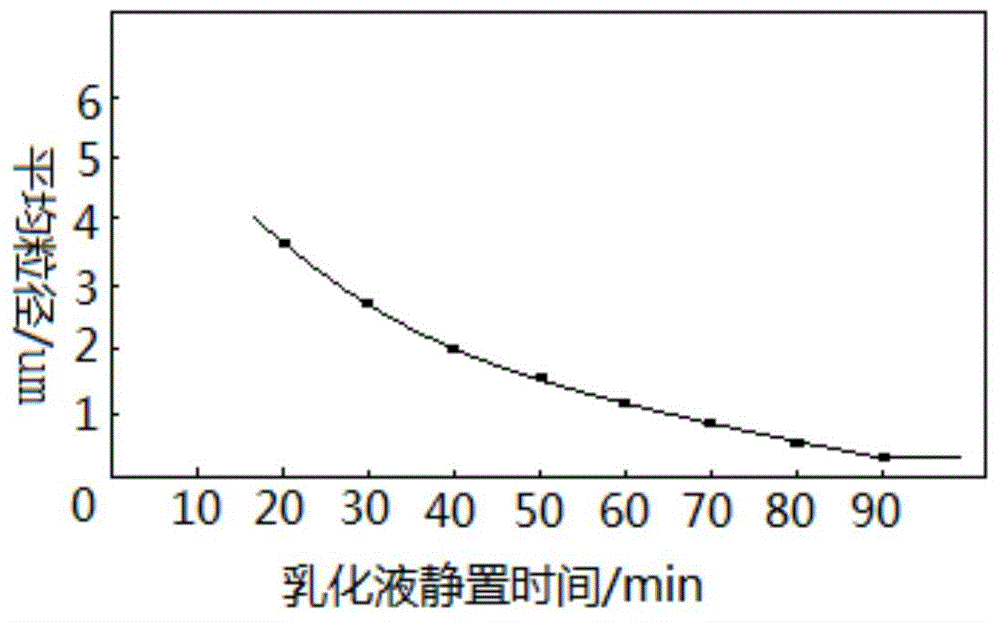

[0033] 3) placing the nanoemulsion obtained above in a sterile dry environment for 1 to 2 days, so that the average particle size of the obtained nanoemulsion is 0.3 to 2 μm;

[0034] 4) Add 120ml of absolute ethanol to the cleaned nanoemulsion emulsion and stir until clear...

Embodiment 2

[0049] Contrast test of nano-vitamin D3, ordinary vitamin D3 and water-soluble vitamin D3 in water.

[0050] The test results are shown in the table below:

[0051]

[0052]

[0053] It can be seen from the above table that the nano-vitamin D3 has the best water solubility, so it can completely meet the needs of the body in the water-soluble medium in the body of livestock and poultry.

Embodiment 3

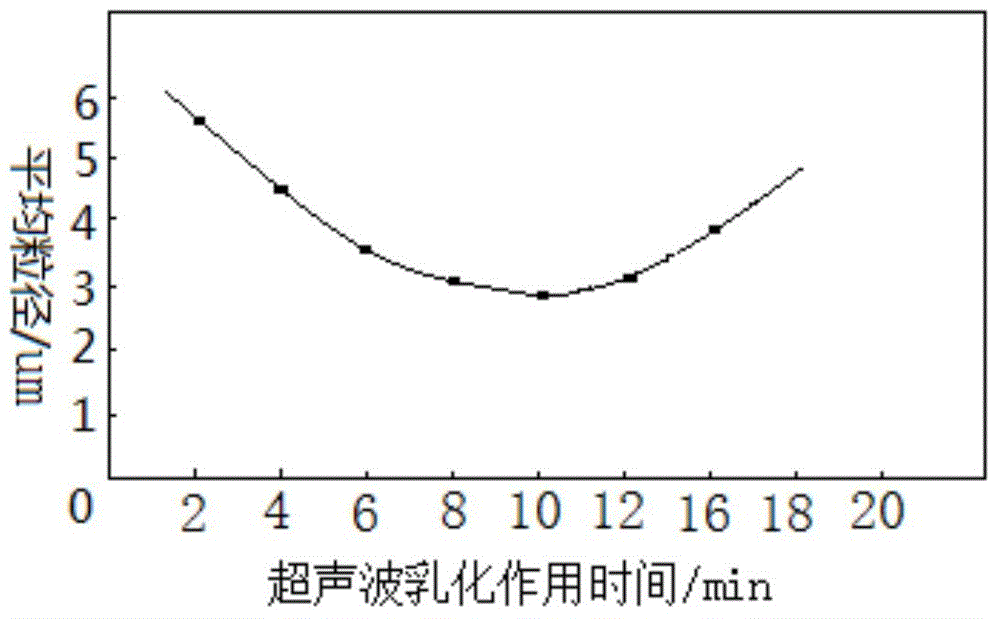

[0055] In the nanoemulsion emulsification process, under different ultrasonic emulsification conditions, the average particle size of the emulsified emulsion has a direct relationship, such as figure 1 As shown, the emulsified particle size obtained in about 10 minutes is the best. figure 1 It is the average particle size change diagram of the ultrasonic emulsification time to the nanoemulsion emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com