Preparation method of cad/cam personalized zirconia one-piece implant

A technology of zirconia and implants, which is applied in implantology, medical science, dentistry, etc., can solve the problems that cannot be widely used, and achieve the effect of less potential risks, fewer complications, and good aesthetic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step (1). Confirm the single tooth loss of the maxillary first molar through oral clinical examination, and analyze the bone height of the patient's edentulous area by oral CBCT to be 8mm, width 9mm, type 2 bone, jaw-gingival distance 6mm, and gingival thickness 3mm;

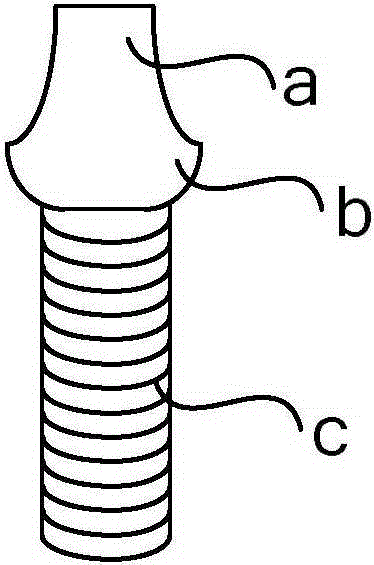

[0026] Step (2), according to the patient’s missing tooth area data obtained in step (1), use exocad software on the computer to design personalized zirconia implant body c thread form, implant body c length and diameter, gingival penetration The height and shape of part b and the height of abutment (such as figure 1 Shown);

example 1

[0027] The design data of Example 1 are as follows: the implant body diameter is 5mm, the body length is 7.5mm, the body shape is columnar, the transgingival height is 2mm, and the abutment height is 5mm.

[0028] Step (3), according to the personalized implant data designed in step (2), use KavoArcticaEngineCAM grinder to process medical zirconia materials to obtain personalized zirconia implants;

[0029] The medical zirconia material contains 4.5% yttrium oxide by mass;

[0030] Step (4). Place the processed personalized zirconia implant in a crystallization furnace at 1440°C for 12 hours, then cool the sintered implant at 10°C / min to 900°C, and then at 5°C / min Cool down to 600°C, then naturally cool to room temperature, and finally perform mechanical polishing on the transgingival part b and upper abutment a of the implant after cooling;

[0031] The mechanical polishing is to polish the implant transgingival part b and abutment a with emery silica gel polishing wheel, and the rou...

Embodiment 2

[0037] Step (1). Confirm the loss of a single maxillary anterior tooth through oral clinical examination, and analyze the bone height of the patient's edentulous area by oral CBCT to be 15mm, width 7mm, type 2 bone, jaw-gingival distance 8mm, and gingival thickness 4mm;

[0038] Step (2), according to the patient’s missing tooth area data obtained in step (1), use exocad software on the computer to design personalized zirconia implant body c thread form, implant body c length and diameter, gingival penetration The height and shape of part b and the height of abutment (such as figure 1 Shown);

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com